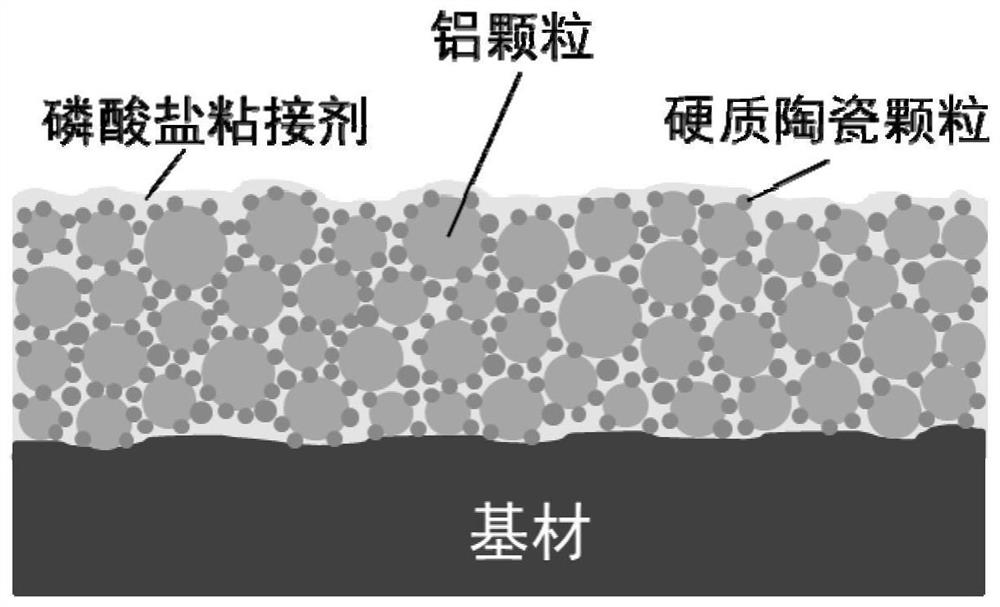

Wear-resistant corrosion-resistant aluminum-based metal ceramic composite coating and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

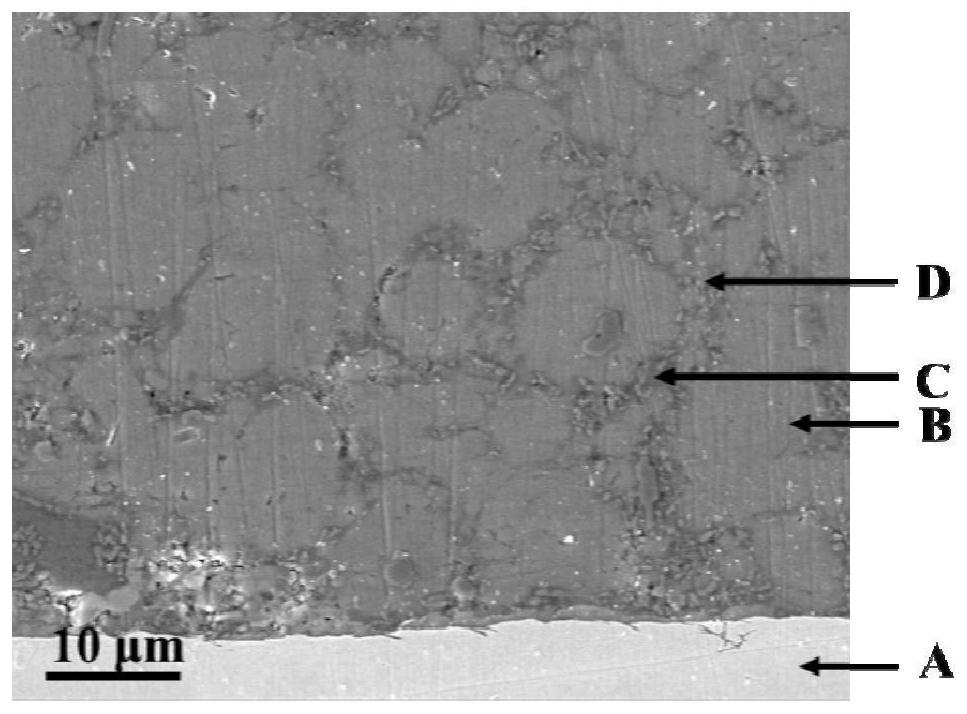

Method used

Image

Examples

Embodiment 1

[0036] An embodiment of the wear-resistant and anti-corrosion aluminum-based cermet composite coating of the present invention, the preparation method of the composite coating described in this embodiment comprises the following steps:

[0037] (1) Treating the base material: degreasing and sandblasting the surface of the 45# steel plate base material. The degreasing treatment adopts high temperature degreasing method, the degreasing temperature is 330°C, and the degreasing time is 1h; sandblasting is used for rust removal and surface activation, the sandblasting pressure is 0.3MPa, the sandblasting distance is 150mm, and the sand particle size is 180 head.

[0038] (2) Preparation of composite coating: the composite coating comprises the following components by weight: 1000 parts of aluminum dihydrogen phosphate, 1000 parts of distilled water, 20 parts of coating additive tetraethyl silicate, 30 parts of passivating agent magnesium chromate, curing agent oxidation A total of...

Embodiment 2

[0044] An embodiment of the wear-resistant and anti-corrosion aluminum-based cermet composite coating of the present invention, the preparation method of the composite coating described in this embodiment comprises the following steps:

[0045] (1) Treating the base material: degreasing and sandblasting the surface of the 304 stainless steel plate base material. Degreasing Treatment Use organic care agent to soak to remove surface grease; use sandblasting for rust removal and surface activation, with a sandblasting pressure of 0.4MPa, a sandblasting distance of 200mm, and a sand particle size of 150 mesh.

[0046] (2) Preparation of composite coating: the composite coating comprises the following components by weight: 1200 parts of aluminum dihydrogen phosphate and potassium dihydrogen phosphate altogether, wherein 800 parts of aluminum dihydrogen phosphate, 1200 parts of distilled water, 35 parts of coating additive orthosilicate 20 parts, 20 parts of passivating agent magnes...

Embodiment 3

[0051] An embodiment of the wear-resistant and anti-corrosion aluminum-based cermet composite coating of the present invention, the preparation method of the composite coating described in this embodiment comprises the following steps:

[0052] (1) Treating the base material: degreasing and sandblasting the surface of the 304 stainless steel plate base material. Degreasing Treatment Use organic care agent to soak to remove surface grease; use sandblasting for rust removal and surface activation, with a sandblasting pressure of 0.5MPa, a sandblasting distance of 200mm, and a sand particle size of 180 mesh.

[0053] (2) Preparation of composite coating: the composite coating comprises the following components by weight: 1200 parts of aluminum dihydrogen phosphate, 1000 parts of distilled water, 40 parts of coating additive tetraethyl silicate, 40 parts of passivating agent magnesium chromate, curing agent oxidation A total of 15 parts of zinc and magnesium oxide, of which the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com