Tail gas sampling device and method for chlorination volatilization system

A sampling device and chlorination volatilization technology, applied in sampling devices, sampling, measuring devices, etc., can solve the problems of pipe wall pollution, no tail gas sampling device, poor cotton adsorption effect, etc., to achieve strong adaptability, improve accuracy and Sampling efficiency, good cohesion capture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

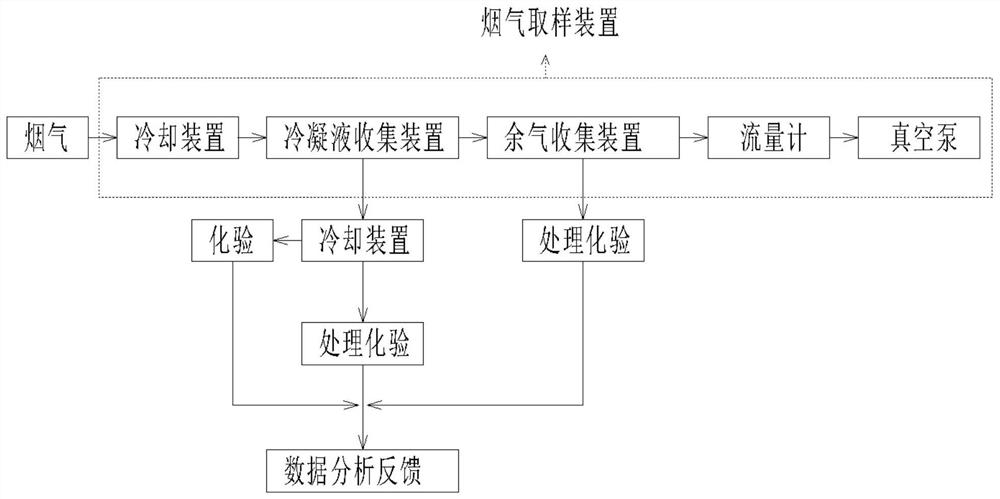

[0034] Example 1, a method for sampling the flue gas of the chlorination and volatilization system was applied in the Xinjiang chlorination and volatilization system. This time, the sampling and testing work was mainly carried out on the tail gas after 2# electrostatic demisting. Its process flow chart is as figure 1 shown, including the following steps:

[0035] A method for sampling tail gas of a chlorination volatilization system, specifically comprising the following steps:

[0036] S1. Sampling device installation

[0037] 1 set of water ring vacuum pump, 1 set of LZB-25 glass rotameter (range 1.6-16m 3 / h), 1 pear-shaped funnel, 1 2500ml suction filter bottle, 3 wide-mouth bottles, 663.79g of activated carbon, several rubber hoses and rubber stoppers, etc. Drill and assemble it so that the extracted exhaust gas passes through in sequence: pear-shaped funnel (the effect of condensing flue gas)-suction filter bottle (collecting flue gas condensate)-jar (built-in activat...

Embodiment 2

[0044] Example 2, a method for sampling the flue gas of the chlorination volatilization system was applied in the chlorination volatilization system in Gansu. This time, the sampling and testing work was mainly performed on the tail gas after the chlorination volatilization absorption system.

[0045] Include the following steps:

[0046] S1. Sampling device installation

[0047] 1 set of water ring vacuum pump, 1 set of LZB-25 glass rotameter (range 1.6-16m 3 / h), 3 spherical condenser tubes, 1 2500ml suction filter bottle, 3 jars, 400g activated carbon, rubber hoses and rubber stoppers, etc.

[0048] It is drilled and assembled so that the extracted exhaust gas passes through in sequence: spherical condenser tube (condensed flue gas effect) - suction filter bottle (collected flue gas condensate) - wide mouth bottle (built-in activated carbon, residual gas absorption) - flow meter (display flow 2.2m 3 / h) - vacuum pump.

[0049] S2. On-site positioning and sampling of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com