High-flux evaluation device and method based on erosive wear performance of composite material

A composite material and wear performance technology, which is applied in the direction of measuring devices, analyzing materials, testing wear resistance, etc., can solve the problems that affect the development speed and popularization and application of erosion-resistant materials, low efficiency, and long test cycle, so as to shorten the detection period And the effect of R&D speed and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

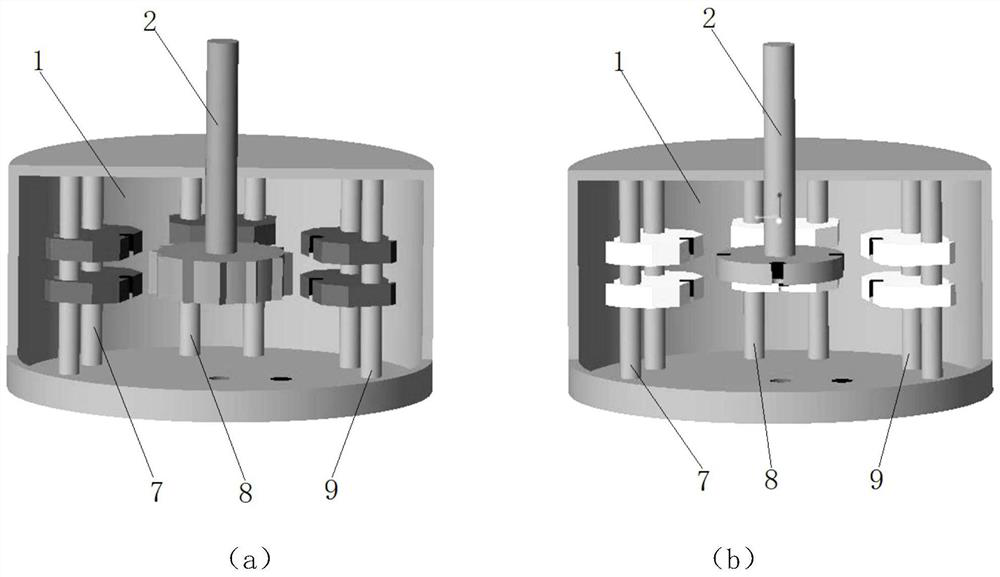

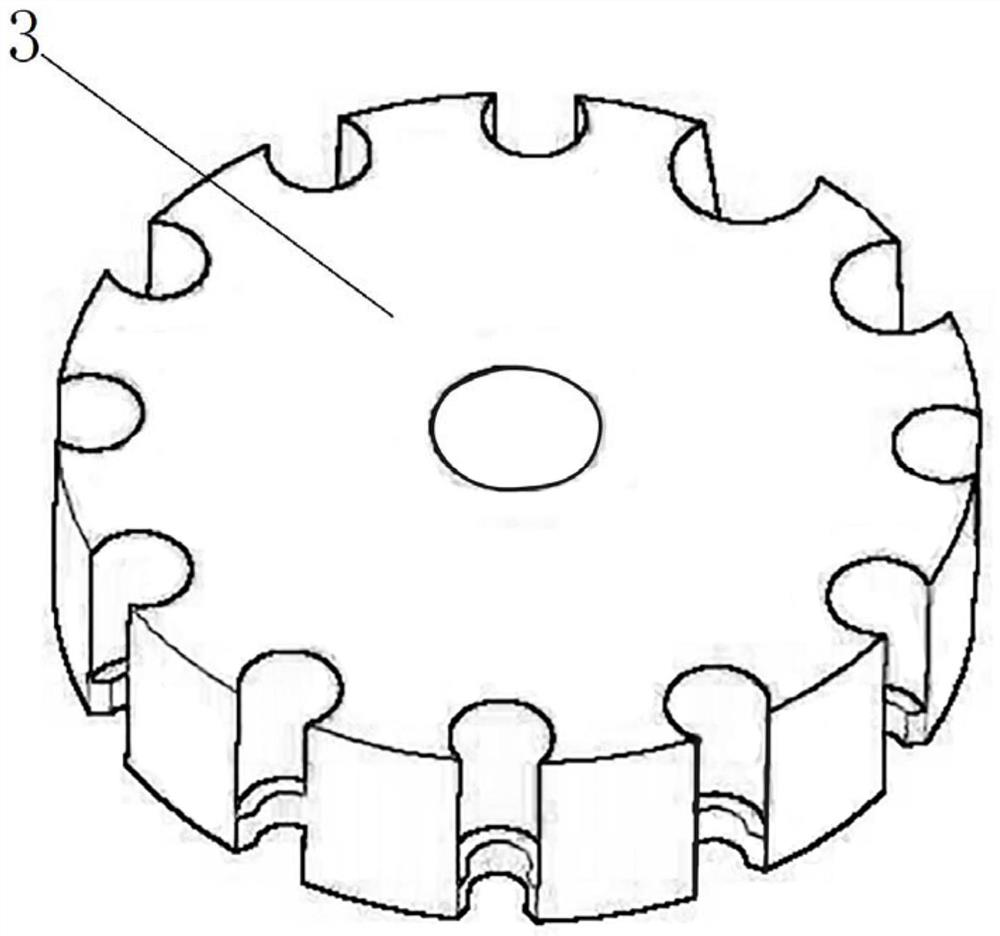

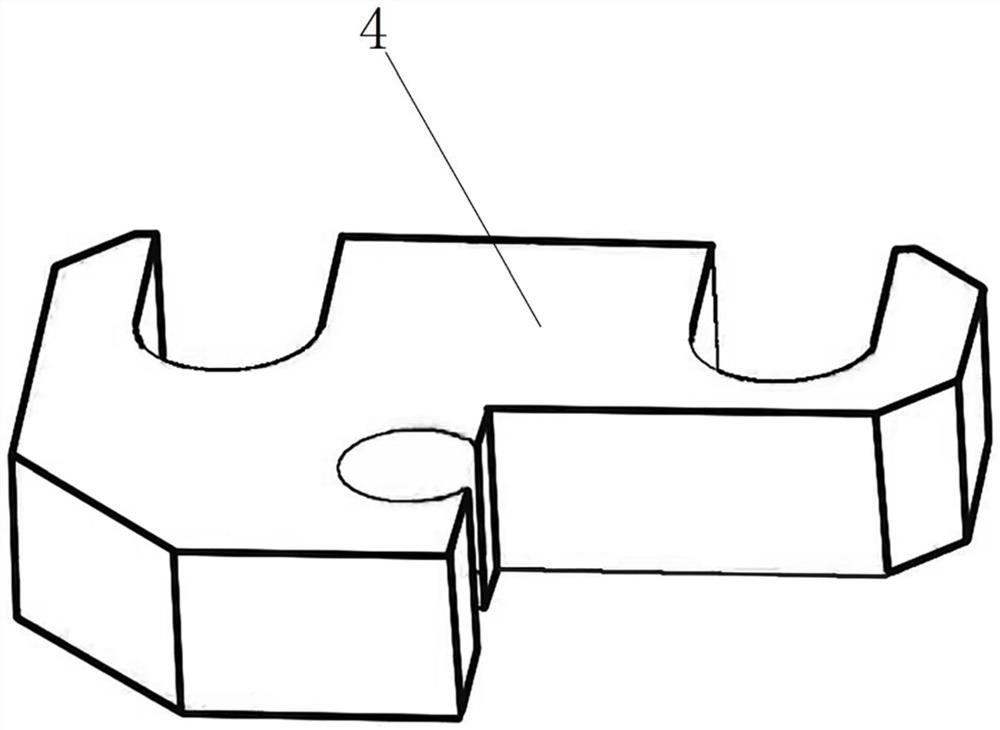

Method used

Image

Examples

Embodiment 1

[0057] 1) Put the sample to be tested into the erosion fixture, select the fixture to fix the sample, and set the erosion angles to 3 groups of 0°, 15°, 30°, 45°, 60°, 75°, and 90° respectively, Install each set of fixtures on 6 sets of fixtures, and connect the sample to the electrochemical measurement system with a test line;

[0058] 2) Prepare alkaline erosion solution components, pH = 10, use 50 mesh SiO 2 Granules, the solid mass fraction accounts for 10%, inject the erosion liquid components into the test chamber;

[0059] 3) Set the erosion rate of the rotating spindle to 800r / min, the test temperature to 25°C, and the test time to 20h, in which a group of samples is taken out every 20 hours for analysis and evaluation.

[0060] After the test, the wear conditions of the samples with different erosion angles and different erosion times were measured with a high-precision analytical balance, and the laser confocal profiler was used to quickly observe the erosion morpho...

Embodiment 2

[0062] 1) First of all, put the sample to be tested for scouring and wear performance into the erosion fixture, select the fixture for sample rotation, the erosion angle is 30°, load 12 groups of samples, and install the fixture on the rotating spindle ;

[0063] 2) Next, prepare the acidic erosion liquid components, pH = 4, use 30 mesh SiC particles, the solid mass fraction accounts for 5%, and inject the erosion liquid components into the test chamber of the erosion wear performance testing device;

[0064] 3) Set the erosion rate to 1000r / min, the test temperature to 30°C, and the test time to 5×12h, in which a group of samples is taken out every 5 hours for analysis and evaluation.

[0065] After the test, the wear of the samples with different erosion times was measured using a high-precision analytical balance, and the laser confocal profiler was used to quickly observe the erosion morphology and degree. As well as scanning electron microscopy to observe the morphology ...

Embodiment 3

[0067] Put the sample to be tested into the erosion fixture, select the fixture to fix the sample, and the erosion angle is 0°, 30°, 60°, 90° in 4 groups, and install each set of fixtures to 6 sets of fixing frames Connect the sample to the electrochemical measurement system with a test line;

[0068] 2) Prepare acidic erosion solution components, pH = 3, use 20 mesh Al 2 o 3 Granules, the solid mass fraction accounts for 15%, inject the erosion liquid components into the test chamber;

[0069] 3) Set the erosion rate of the rotating spindle to 1500r / min, the test temperature to 45°C, and the total test time to 40h, in which a group of samples is taken out every 10 hours for analysis and evaluation.

[0070] After the test, the wear conditions of the samples with different erosion angles and different erosion times were measured with a high-precision analytical balance, and the laser confocal profiler was used to quickly observe the erosion morphology and degree. As well as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com