Infrared long-wave cut-off filter and preparation method thereof

A cut-off filter, long-wave technology, applied in the direction of filters, optics, optical components, etc., can solve the problems of less variety of infrared film materials and difficult preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

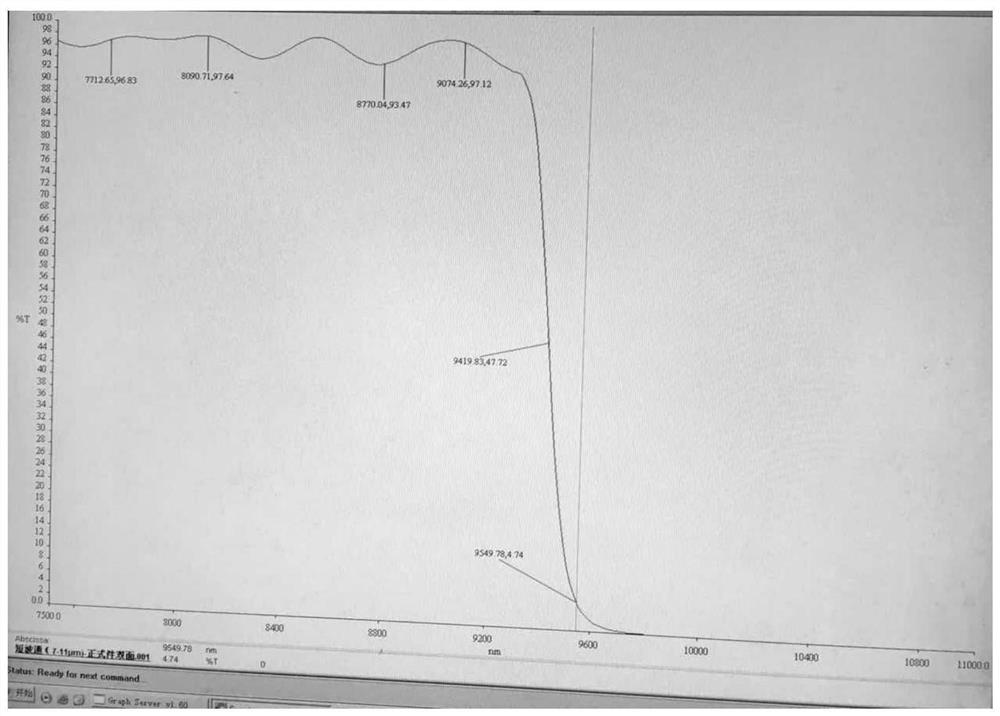

Image

Examples

Embodiment

[0052] An infrared long-wave cut-off filter, the film structure of the filter is:

[0053] MLMHM|Sub|(MH)^11M

[0054] Among them, Sub is the substrate, (MH)^11M is the short-wave pass filter film system, MLMHM is the anti-reflection film system, H is the Ge film layer, M is the ZnS film layer, and L is the YbF film 3 film layer.

[0055] The substrate is a Ge substrate.

[0056] A preparation method of an infrared long-wave cut-off filter, comprising the steps of:

[0057] Step 1: Coating an anti-reflection film system on one side of the germanium substrate;

[0058] Step 1.1: Clean the substrate and bombard it with an ion source for 3 to 5 minutes;

[0059] Step 1.2: Bake the substrate and evacuate to 1×10 -3 Pa, heat the substrate to 120°C and keep it warm for 1 hour;

[0060] Step 1.3: Plating the first layer of film, using ZnS film material for evaporation, and using ion source to assist deposition, the pressure of the vacuum chamber during evaporation is 5×10 -3 P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com