A microscopic model of carbonate reservoir and its preparation method and application

A technology of carbonate reservoirs and microscopic models, applied in teaching models, educational tools, instruments, etc., can solve problems affecting the contact angle between water and calcium carbonate surface, affecting experimental results, etc., and achieves simple, fast and fast preparation methods Accelerated, strong pressure-bearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The present embodiment provides a method for preparing a carbonate reservoir microscopic model, which includes the following steps:

[0056] 1. Calcite crystal cutting:

[0057] (1) Crystal slicing: Cut the calcite crystal into crystal slices with a thickness of 3-4 mm using a thin saw or a precision wire cutter.

[0058] (2) Grinding of crystal slices: Use digitally controlled precision machining lathes to grind the crystal slices to ensure that both sides are smooth and flat, in preparation for subsequent uniform etching and bonding.

[0059] (3) Cleaning of crystal slices: Rinse the calcite crystal slices with ethanol and ether respectively, then rinse the surface with deionized water for 3 minutes, and place them in an oven at 105°C for 2 hours to dry after rinsing.

[0060] 2. Preparation of protective coating:

[0061] (1) Production of wax coating: put the crystal sheet into a beaker heated to 160°C filled with molten beeswax and soak for 1 min, then take it ou...

Embodiment 2

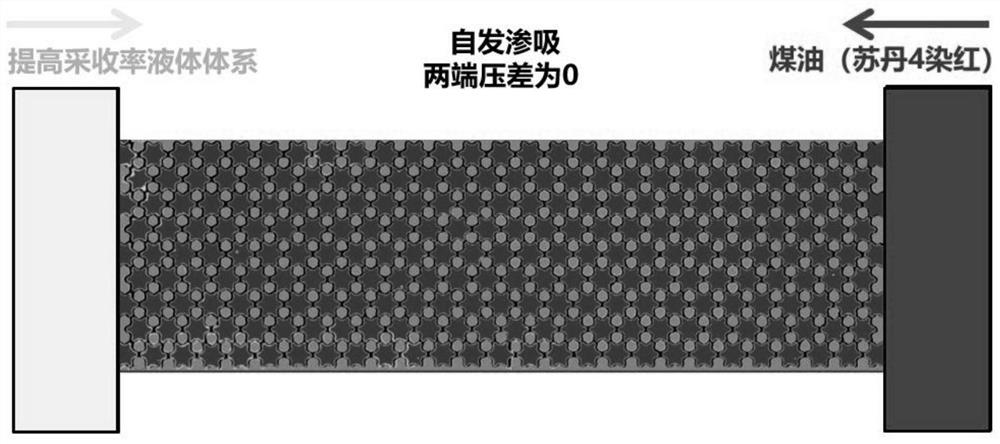

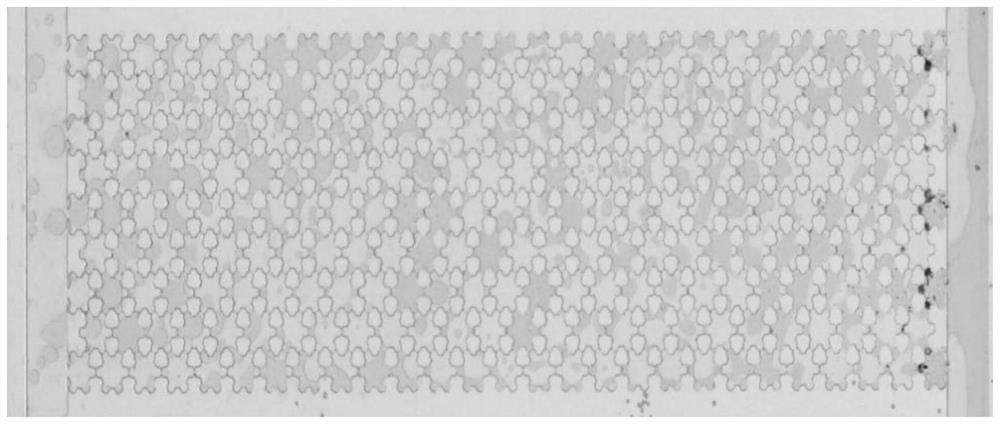

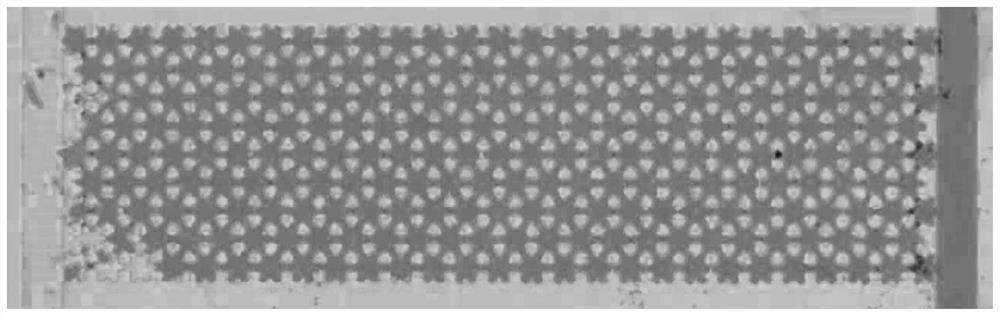

[0076] Adopt the method for preparing the microscopic model of carbonate rock reservoir in embodiment 1, design the model pattern channel to be many regular 2.5D hexagonal channels of etching, the inlet and outlet channels on both sides are parallel straight channels, and the length is 100mm. The channel width is 100 μm (such as figure 1 Shown), according to the method of embodiment 1, preparation obtains the microscopic model of carbonate rock reservoir, this model is used in the research of water injection development of carbonate rock, and concrete operation is as follows:

[0077] The Sudan 4 red-dyed kerosene was injected from the inlet and outlet channels on both sides until the model was fully saturated with kerosene, and then the inlet and outlet channels on both sides were simultaneously injected with kerosene and EOR liquid system with enhanced water injection effect at the same pressure and constant pressure. The pressure on both sides is the same, and the pressure ...

Embodiment 3

[0080] Adopt the method for preparing the microscopic model of the carbonate rock reservoir in Example 1, design the channel of the model pattern to be a straight channel, the width of the straight channel is inconsistent, and the intervals of 30 μm and 120 μm are arranged (in order to be consistent with the occurrence of remaining oil in the water injection process, by observing the remaining oil The contact angle between oil and wall surface and water, to judge the effect of enhanced oil recovery liquid system with enhanced water injection effect), prepare and obtain the microscopic model of carbonate rock reservoir according to the method of Example 1, and use this model to judge the effect of enhanced oil recovery liquid system The research on the effect of the enhanced oil recovery liquid system of the water injection effect, the specific operation is as follows:

[0081] Inject Sudan 4 red-dyed kerosene from the injection port of the model until the model is fully saturat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com