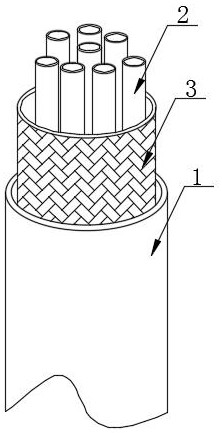

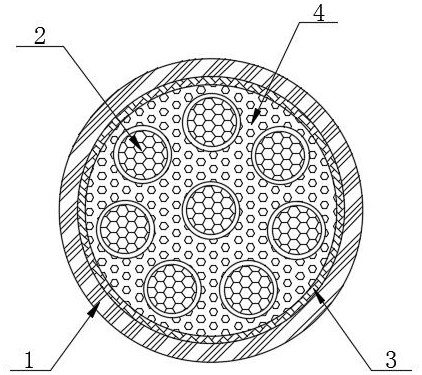

Composite cable and preparation process thereof

A preparation process and composite technology, applied in cable/conductor manufacturing, insulating cables, insulating conductors/cables, etc., can solve the problems of poor cable strength, general torsion resistance, poor fire resistance, etc., and achieve improved strength and length. The effect of increasing and decreasing cross-section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

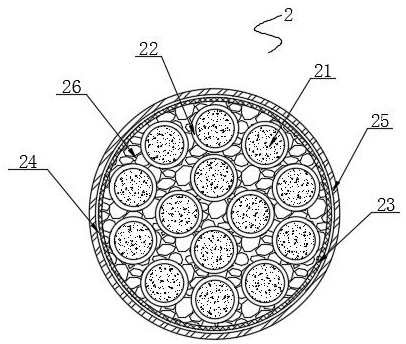

[0030] S1. Preparation of filling material 26: Select 15 parts of vulcanization-free rubber and 7 parts of anti-aging agent, pour the selected raw materials into the mixer, start the mixer to stir, control the temperature during stirring at 180°C, and stir for 45 minutes , the stirring rate of the mixer is controlled at 175 rpm, so that it is fully mixed, and then 8 parts of rubber filler oil, 10 parts of zinc oxide and 11 parts of coupling agent are added, and the stirring is continued. The stirring temperature is controlled at 240 ° C. The time is 65 minutes, the stirring rate of the mixer is controlled at 175 rpm, and the filling material 26 can be obtained after mixing it evenly;

[0031] S2, preparation of cable core 2: use copper plate as raw material, place it in a smelting furnace for smelting, after the copper plate is completely melted, inject molten copper in a rolling machine into a rolling machine and let it cool naturally for 2.5 hours before rolling. The time is...

Embodiment 2

[0035] S1. Preparation of filling material 26: Select 10 parts of vulcanization-free rubber and 5 parts of anti-aging agent, pour the selected raw materials into the mixer, start the mixer to stir, the temperature during stirring is controlled at 160°C, and the stirring time is 30 Minutes, the stirring rate of the mixer is controlled at 150 rpm, so that it is fully mixed, and then 6 parts of rubber filler oil, 8 parts of zinc oxide and 10 parts of coupling agent are added, and the stirring is continued. The stirring temperature is controlled at 200 ° C. The time is 50 minutes, the stirring rate of the mixer is controlled at 150 rpm, and the filling material 26 can be obtained after mixing it evenly;

[0036] S2, preparation of cable core 2: use copper plate as raw material, place it in a smelting furnace for smelting, after the copper plate is completely melted, inject molten copper in a rolling machine into a rolling machine and let it cool naturally for 2 hours before rolling...

Embodiment 3

[0040] S1. Preparation of filling material 26: Select 20 parts of vulcanization-free rubber and 10 parts of anti-aging agent, pour the selected raw materials into the mixer, start the mixer to stir, control the temperature at 200°C during stirring, and stir for 60 minutes , the stirring speed of the mixer is controlled at 200 rpm, so that it is fully mixed, and then 10 parts of rubber filler oil, 12 parts of zinc oxide and 12 parts of coupling agent are added, and the stirring is continued. The stirring temperature is controlled at 280 ° C. The time is 80 minutes, the stirring rate of the mixer is controlled at 200 rpm, and the filling material 26 can be obtained after mixing it evenly;

[0041] S2, preparation of cable core 2: use copper plate as raw material, place it in a smelting furnace for smelting, after the copper plate is completely melted, inject molten copper in a rolling machine into a rolling machine and let it cool naturally for 3 hours before rolling. The time i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com