Preparation method and application of sulfur-doped tin disulfide/tin dioxide@C/rGO material

A technology of tin disulfide and tin dioxide, which is applied in the repair/maintenance of secondary batteries, secondary batteries, electrochemical generators, etc., can solve problems such as electrode pulverization failure, improve conductivity, and increase electron-absorbing ability , to promote the effect of stable generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

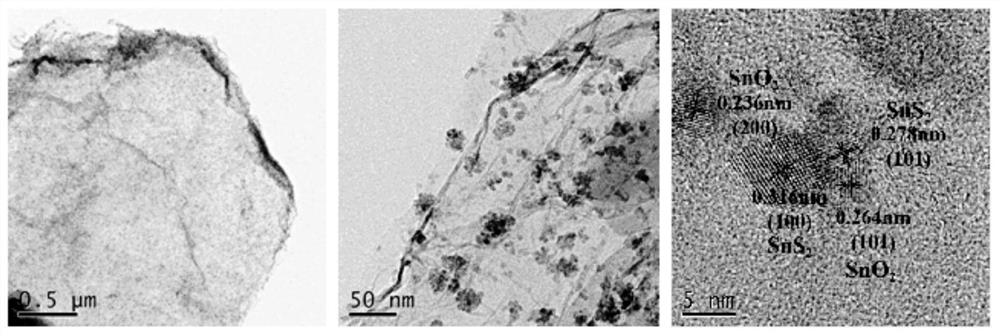

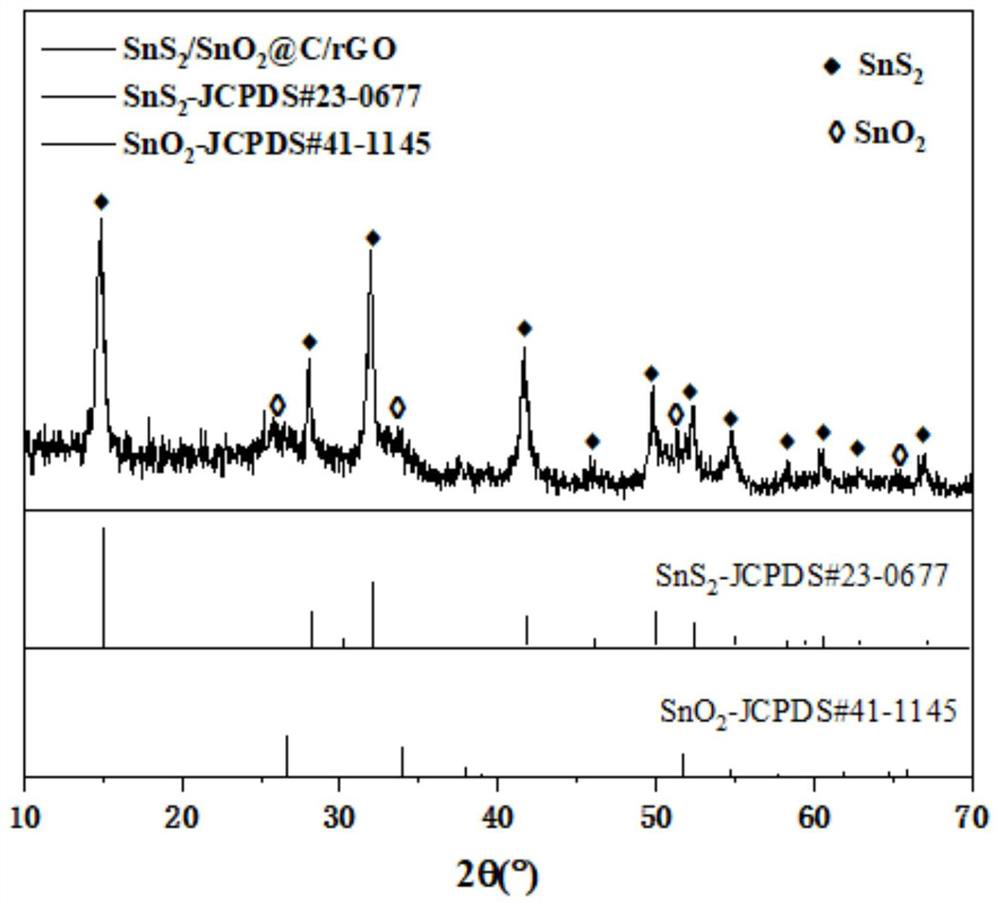

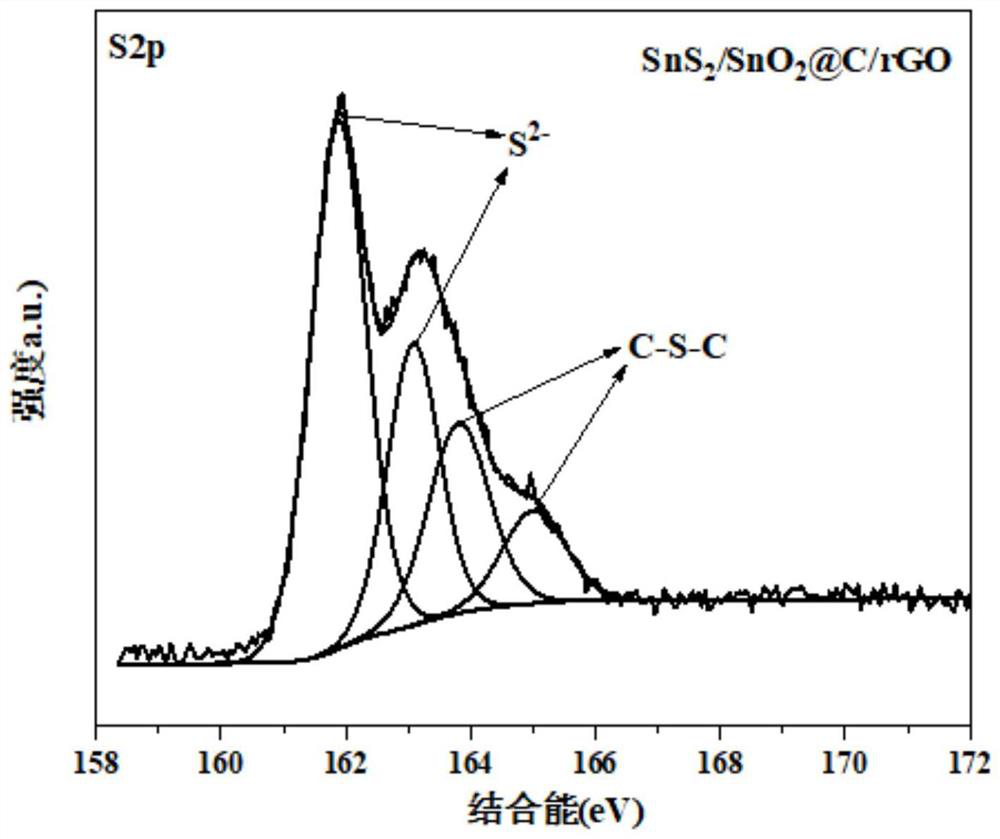

Image

Examples

Embodiment 1

[0026] All raw materials used in Example 1 are commercially available products.

[0027] Example 1

[0028] A sulfur-doped SnS 2 / SnO 2 @C / rGO nanocomposite preparation method, the specific steps are:

[0029] (1) Weigh 0.5g SnCl 2 Dissolve in 0.4mL of concentrated HCl (mass concentration: 37%) and stir evenly to form SnCl 2 acid;

[0030] (2) 0.4mL of SnCl 2 Add the acid solution to 343mL of distilled water, and at the same time add 267.5mg of L-ascorbic acid, stir magnetically until it is completely dissolved; finally add 107mL of GO colloid (concentration: 5mg / mL) and 50mL of thiourea solution (50mg / mL) to the above solution , stir evenly to form a mixed solution A;

[0031](3) Place the solution A obtained in step (2) in a water bath at 80°C, and evaporate the solution A under negative pressure at a pressure of -0.1Pa. After the solution A evaporates to 100mL, transfer the formed gel to the hydrothermal kettle at 1°C·min -1 The heating rate is at 180°C, hydrotherm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com