Method and apparatus for producing desulfurizing agent, and method for removing sulfur dioxide from cement kiln exhaust gas

A manufacturing method and technology for manufacturing devices, which are applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of difficult adjustment of moisture content, changes in CaO digestibility, clogging of spray nozzles, etc., and achieve small changes in digestibility. , Easy to adjust the moisture content, maintain the effect of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Next, modes for implementing the present invention will be described with reference to the drawings.

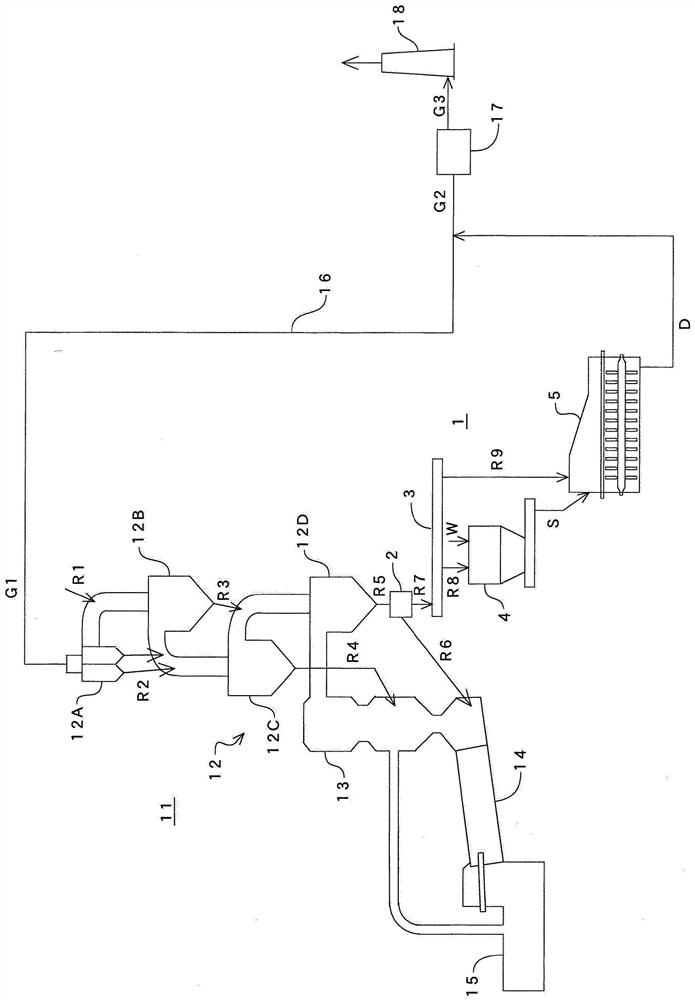

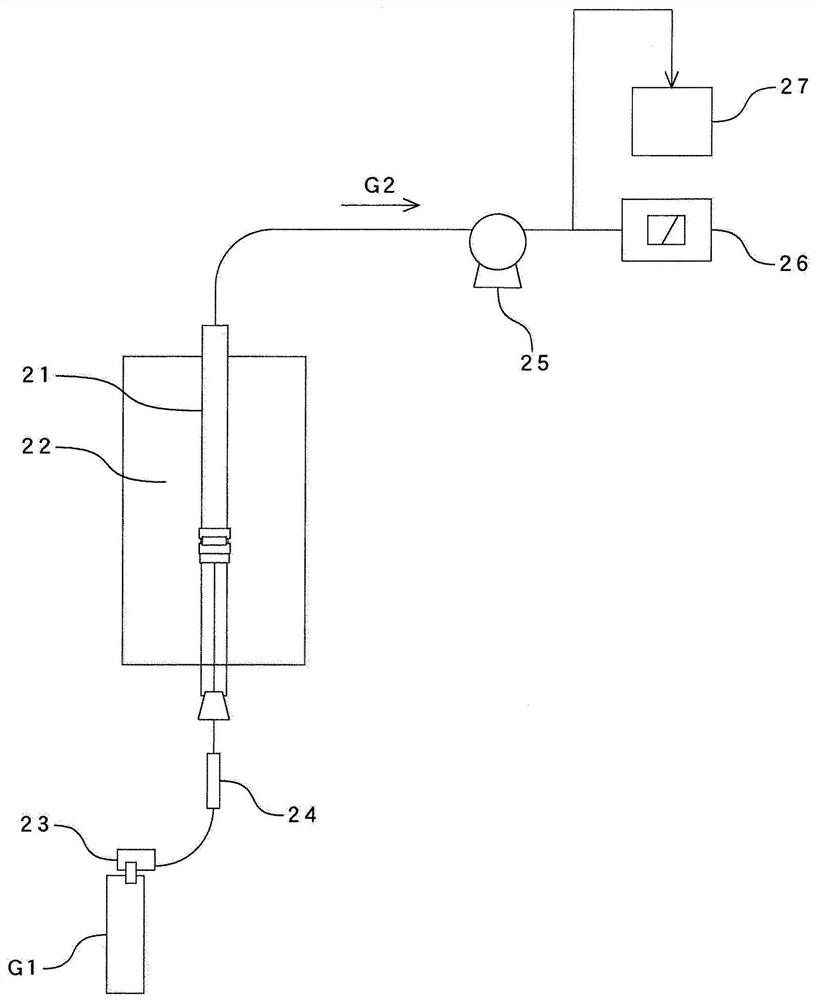

[0025] figure 1 One embodiment of the desulfurizing agent manufacturing apparatus according to the present invention is shown, and this desulfurizing agent manufacturing apparatus 1 is attached to a cement burning apparatus 11 .

[0026] The cement burning device 11 includes a preheater 12, a preburner 13, a cement kiln 14, a clinker cooler 15, etc. The cement raw material R1 put into the preheater 12 from the raw material supply system is preheated in the preheater 12, The clinker is prefired in the calciner 13 , fired in the cement kiln 14 , and cooled in the clinker cooler 15 .

[0027] The preheater 12 is composed of four stages of cyclones 12A to 12D, preheats the cement raw material R1 put into the inlet pipeline of the uppermost cyclone 12A with the cyclones 12B and 12C, and preheats the preheated raw material R4 discharged from the cyclone 12C After calcining...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com