Gear material and production process thereof

A production process and gear technology, applied in the field of gears, can solve the problems of high procurement costs and lack of market competitiveness, and achieve the effects of low scrap rate, improved overall competitiveness, and low production and procurement costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

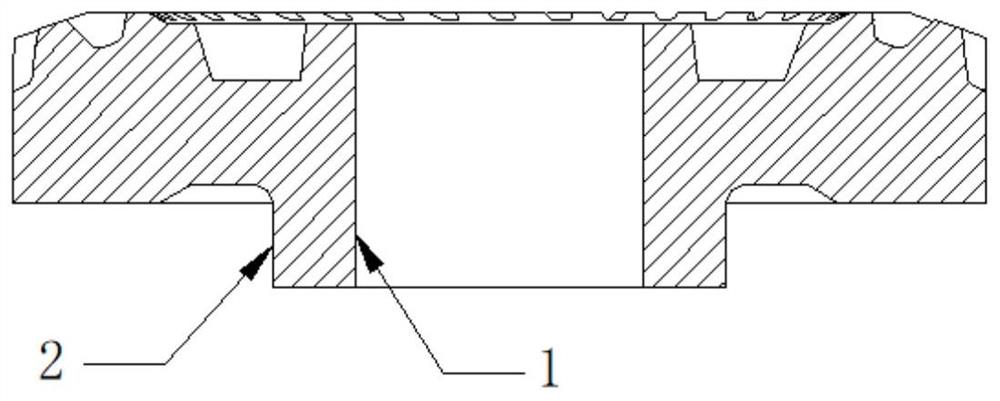

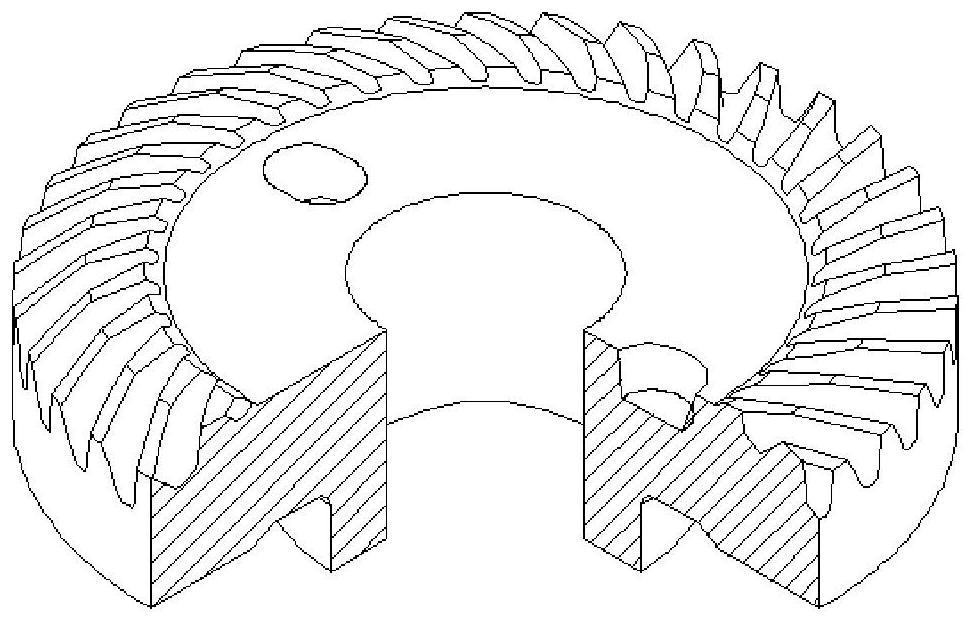

Image

Examples

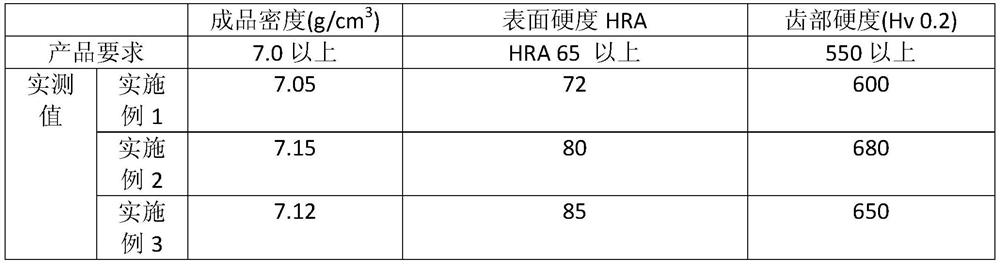

Embodiment 1

[0027] A kind of gear material, wherein: comprise the raw material of following weight part: 420 parts of water atomized iron powders, 2.5 parts of copper powders, 2 parts of graphites, 15 parts of nickel powders, 3 parts of molybdenum powders and 1.5 parts of lubricants, lubricants are Kenolube P11.

[0028] A gear production process, wherein: comprising the following steps:

[0029] (1) Mixing: In parts by weight, add 2 parts of graphite, 1.5 parts of lubricant and 60 parts of water-atomized iron powder into a biconical mixer and mix for 10 minutes to obtain primary mixed powder. For 3 equal parts as ready-mixed powder, add the remaining 360 parts of water-atomized iron powder into the double-cone mixer, and add 2.5 parts of copper powder, 15 parts of nickel powder, 3 parts of molybdenum powder and one part of pre-mixed powder to stir After 15 minutes, add a portion of premix powder and stir for 15 minutes, and finally add a portion of premix powder and stir for 15 minutes ...

Embodiment 2

[0035] A gear material, wherein: comprising the following raw materials in parts by weight: 450 parts of water atomized iron powder, 10 parts of copper powder, 3 parts of graphite, 20 parts of nickel powder, 5 parts of molybdenum powder and 2 parts of lubricant, the lubricating The agent is Kenolube P11.

[0036] A gear production process, wherein: comprising the following steps:

[0037] (1) Mixing: In parts by weight, add 3 parts of graphite, 2 parts of lubricant and 80 parts of water-atomized iron powder into a biconical mixer and mix for 15 minutes to obtain primary mixed powder. For 3 equal parts as ready-mixed powder, add the remaining 370 parts of water-atomized iron powder into the double-cone mixer, and add 10 parts of copper powder, 20 parts of nickel powder, 5 parts of molybdenum powder and one part of pre-mixed powder to stir 20 minutes, then add a portion of ready-mix powder and stir for 20 minutes, finally add a portion of pre-mix powder and stir for 15 minutes ...

Embodiment 3

[0043] A kind of gear material, wherein: comprise the raw material of following weight part: 480 parts of water atomized iron powders, 15 parts of copper powders, 4 parts of graphites, 40 parts of nickel powders, 8 parts of molybdenum powders and 4 parts of lubricants; The agent is Kenolube P11.

[0044] A gear production process, wherein: comprising the following steps:

[0045] (1) Mixing: In parts by weight, add 4 parts of graphite, 4 parts of lubricant and 100 parts of water-atomized iron powder into a biconical mixer and mix for 20 minutes to obtain primary mixed powder. For 3 equal parts as ready-mixed powder, add the remaining 380 parts of water-atomized iron powder into the double-cone mixer, and add 15 parts of copper powder, 40 parts of nickel powder, 8 parts of molybdenum powder and one part of pre-mixed powder to stir After 25 minutes, add a portion of ready-mix powder and stir for 25 minutes, and finally add a portion of pre-mix powder and stir for 25 minutes to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com