Carbon fiber composite material front-end reinforcing beam and preparation method thereof

A composite material and reinforcing beam technology, which is applied in the field of auto parts to achieve the effects of excellent rigidity, excellent comprehensive performance and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

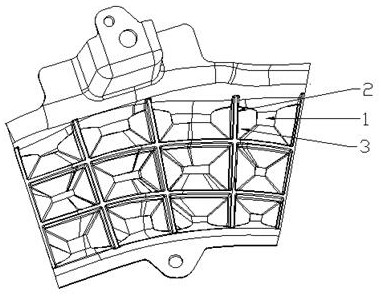

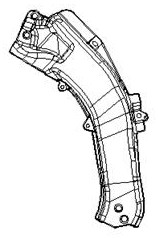

[0028] The present invention discloses a carbon fiber composite material front reinforced beam, which has a left front reinforced beam and a right front reinforced beam, including a reinforced beam body 1 and a rib 2; the reinforced beam body 1 is designed as a bow with a bending radius of 8-12mm type structure, the thickness of the reinforcing beam body 1 is 3 mm, and the flange height of its edge is 16-24 mm; the reinforcing ribs 2 are distributed on the back of the reinforcing beam body 1 in a grid pattern; There is also a reinforcement layer 3 with variable wall thickness around; the thickness of the reinforcement layer 3 gradually decreases from the side of the reinforcement 2 to the side of the reinforcement beam body 1; the reinforcement beam body 1, reinforcement 2 It is integrally formed with the reinforcing layer 3. Through the structural design of the reinforcement beam body 1, the design of the reinforcement rib 2 and the reinforcement layer 3, the overall rigidity...

Embodiment 2

[0033] A method for preparing a front-end reinforced beam of a carbon fiber composite material. The raw material of the carbon fiber SMC sheet is an epoxy vinyl resin system, the mass percentage of the fiber is 53%, and the length of the carbon fiber is 25-26 mm.

[0034] The forming mold selected is a metal mold with one mold and two cavities. The mold temperature is controlled at 135°C by an oil temperature controller.

[0035] The thickness of the front reinforcing beam body 1 is designed to be 3 mm, the thickness of the reinforcing layer 3 from the end point on the side near the reinforcing rib 2 to the opposite side of the reinforcing beam body 1 is 4 mm; the thickness of the reinforcing rib 2 is 3 mm.

[0036] Described preparation method specifically comprises the following steps:

[0037] (1) Raw material punching and layering: place the carbon fiber SMC sheet on the punch platform, and form the reinforcing beam body into a sheet of the required shape and size at the ...

Embodiment 3

[0045] A method for preparing a front reinforced beam of carbon fiber composite material. The raw material carbon fiber SMC sheet is an epoxy resin system, the mass percentage of the fiber is 50-52%, and the length of the carbon fiber is 25-26mm.

[0046] The forming mold selected is a metal mold with one mold and two cavities. The mold temperature is controlled at 145°C by an oil temperature controller.

[0047] The thickness of the front reinforcing beam body 1 is designed to be 3 mm, the thickness of the reinforcing layer 3 from the end point on the side near the reinforcing rib 2 to the opposite side of the reinforcing beam body 1 is 4 mm; the thickness of the reinforcing rib 2 is 3 mm.

[0048] Described preparation method specifically comprises the following steps:

[0049] (1) Raw material punching and layering: place the carbon fiber SMC sheet on the punch platform, and form the reinforcing beam body into a sheet of the required shape and size at the punching place of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com