A multi-scale micro-nano particle composite solder paste for electronic packaging field and preparation method thereof

A technology of micro-nano particles and electronic packaging, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of easy oxidation of nano-Cu solder paste, uneven particle distribution, poor electromigration resistance, etc., and achieve improved anti-electromigration Performance, simple process, and the effect of increasing electrical and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

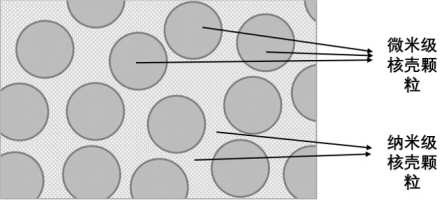

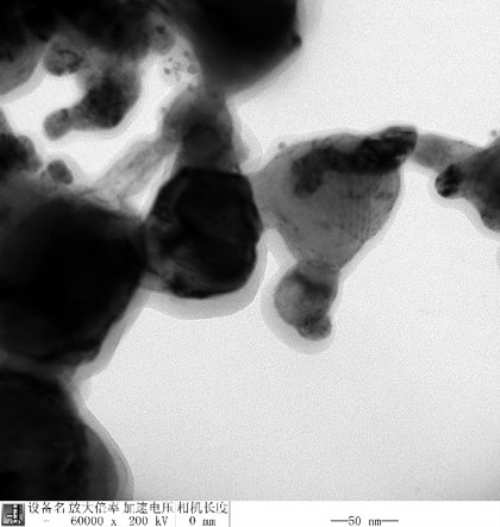

[0044] Example 1 Preparation of particles with a particle size of 30-70nm Cu@Ag core-shell structure.

[0045] The first step is to weigh 1g of copper powder with a particle size of about 50nm, add it to a sulfuric acid solution with a volume concentration of 20%, and perform centrifugation and washing.

[0046] In the second step, mix the silver nitrate solution with a concentration of 0.08g / L and 3.2% sodium hydroxide solution, and then add ammonia water with a mass fraction of 20% drop by drop until the precipitation disappears, that is, a silver ammonia solution is prepared.

[0047] The third step is to mix absolute ethanol and deionized water according to the volume ratio of 1:4, add 40ml of ethanol, 160ml of deionized water, add the copper powder treated in step 1, add 0.5g of dispersant PVP, and at the same time Add the above prepared silver ammonia solution and 0.75g reducing agent hydrazine hydrate, adjust the pH value of the reaction solution to 9~13, and stir the r...

Embodiment 2

[0049] Example 2 Preparation of particles with a particle size of 3-7 μm Cu@Ag core-shell structure.

[0050] The first step is to weigh 1 g of copper powder with a particle size of about 5 μm, add it to a sulfuric acid solution with a volume concentration of 20%, and perform centrifugation and washing.

[0051] The second step is to prepare silver ammonia solution: mix the silver nitrate solution with a concentration of 0.2625g / L and 3.2% sodium hydroxide solution, and then add ammonia water with a mass fraction of 20% drop by drop until the precipitation disappears, that is, silver ammonia is prepared solution.

[0052] The third step is to mix absolute ethanol and deionized water according to the volume ratio of 1:4, add 40ml of ethanol, 160ml of deionized water, add the copper powder treated in step 1, add 0.5g of dispersant PVP, and at the same time Add the above prepared silver ammonia solution and 0.75g reducing agent hydrazine hydrate, adjust the pH value of the react...

Embodiment 3

[0054] Example 3 Preparation of particles with a particle size of 15-25 μm Cu@Ag core-shell structure.

[0055] The first step is to weigh 1 g of copper powder with a particle size of about 20 μm, add it to a sulfuric acid solution with a volume concentration of 20%, and perform centrifugation and washing.

[0056] In the second step, mix the silver nitrate solution with a concentration of 0.6575g / L and 3.2% sodium hydroxide solution, and then add ammonia water with a mass fraction of 20% drop by drop until the precipitate disappears, that is, a silver ammonia solution is prepared.

[0057] The third step is to mix absolute ethanol and deionized water according to the volume ratio of 1:4, add 40ml of ethanol, 160ml of deionized water, add the copper powder treated in step 1, add 0.5g of dispersant PVP, and at the same time Add the above prepared silver ammonia solution and 0.75g reducing agent hydrazine hydrate, adjust the pH value of the reaction solution to 9~13, stir the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com