An agricultural waste water treatment device

A treatment device and agricultural wastewater technology, which is applied in animal husbandry wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of fluid state, difficult deep processing, long sedimentation time, etc., and achieve improvement Speed, fast solid-liquid separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

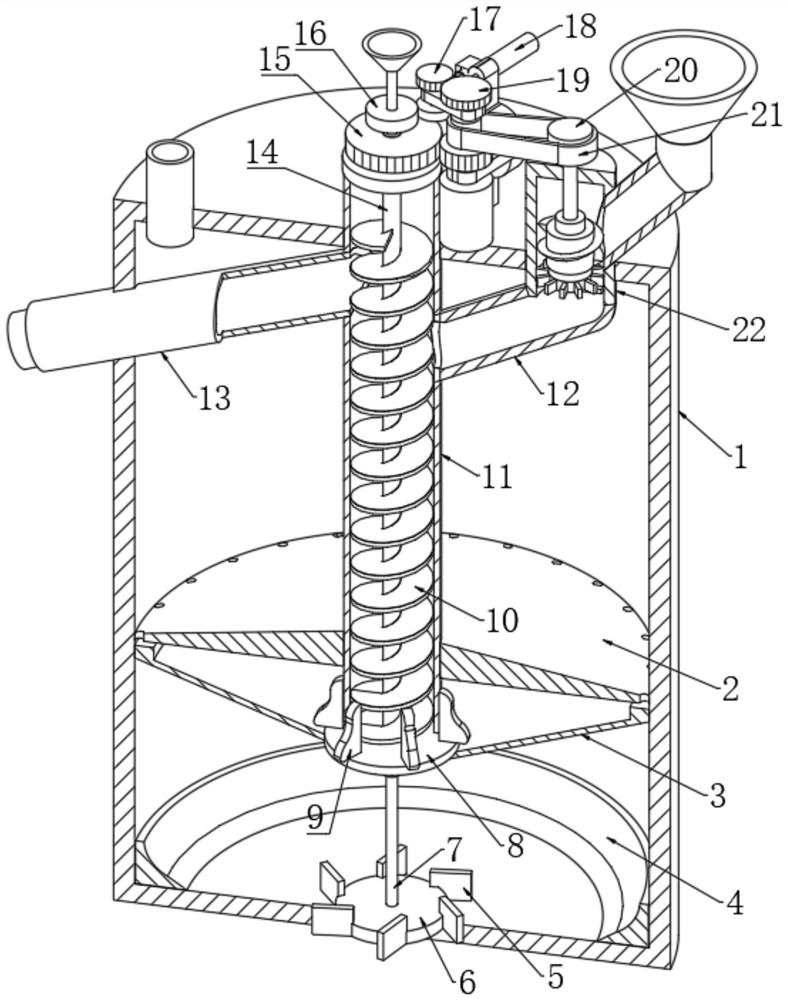

[0026] An agricultural waste water treatment device includes a tank body 1, a sleeve 11 is fixedly connected to the center of the upper end of the tank body 1 through a round opening, a sealing plate is fixedly connected to the upper end of the sleeve 11, and the center of the sealing plate rotates through a first rolling bearing A rotating shaft 14 is connected, the shaft wall of the rotating shaft 14 is fixedly connected with a gear ring 15, the lower end of the rotating shaft 14 extends into the sleeve 11 through the first sealing bearing and is fixedly connected with the spiral blade 10, and the tank body 1 is provided with a conical plate 2. The center of the conical plate 2 is slidably sleeved with the pipe wall of the casing 11 through a circular hole. The tank body 1 is located below the conical plate 2 and is fixedly connected with a filter plate 3 with an inverted conical structure. A circular plate 8 is provided, the upper end of the circular plate 8 is evenly and fi...

Embodiment 2

[0028] Embodiment 2: What is different based on Embodiment 1 is;

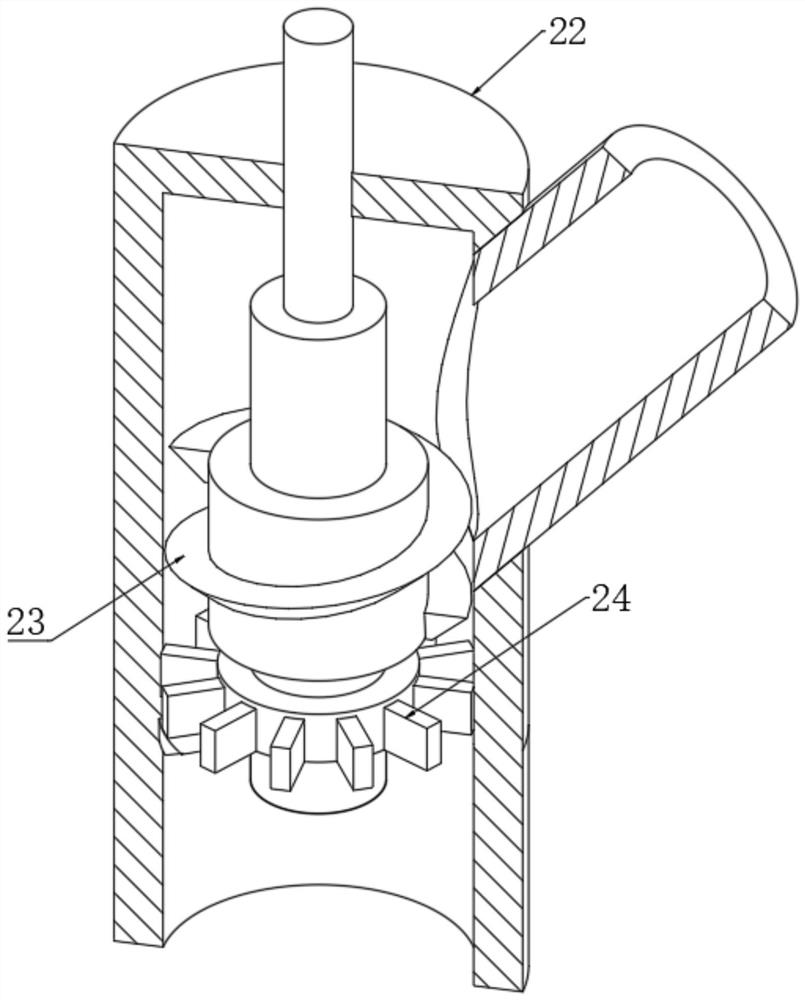

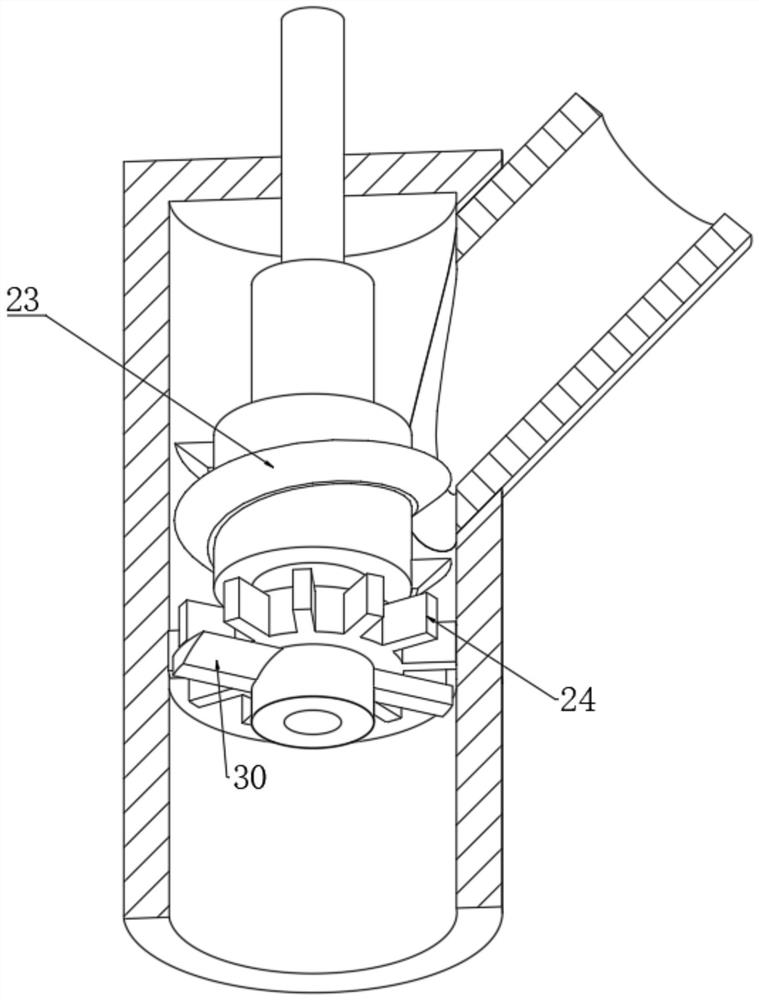

[0029] The crushing mechanism includes a transmission shaft that is vertically rotatably connected to the housing 22 through a second rolling bearing. The upper end of the transmission shaft passes through the second rolling bearing and is fixedly connected with a second pulley 20. The first pulley 27 and the second pulley 20 are connected together. A transmission belt 21 is wound around, a helical roller knife 23 is fixedly connected to the shaft wall of the transmission shaft, a plurality of baffles 24 are fixedly connected in the casing 22, and a positioning ring is fixedly connected to the opposite side of the plurality of baffles 24 together, and The positioning ring is slidably sleeved with the shaft wall of the transmission shaft. Two blades 30 are fixedly connected to the shaft wall of the transmission shaft. The upper ends of the two blades 30 are both slidably connected to the lower end of the baffle p...

Embodiment 3

[0031] Embodiment 3: The difference based on Embodiment 1 is;

[0032] The mixing mechanism includes a disc 6 fixed on the lower end of the liquid inlet pipe 7, the edge of the disc 6 is fixedly connected with a plurality of evenly distributed spoilers 5, and the inner wall of the lower end of the tank body 1 is fixedly connected with an annular block 4. The inner corner of 4 is provided with an arc surface, one side of the transmission wheel 16 is slidably connected with a rubber wheel 31, the upper end of the rubber wheel 31 is fixedly connected with a connecting shaft, and the upper end of the connecting shaft is fixedly connected with the third gear 17. A gear 19 meshes with the third gear 17, a fixed rod 32 is rotatably connected to the shaft wall of the transmission shaft through a second sealed bearing, and the rod wall of the fixed rod 32 is rotatably connected to the shaft wall of the main shaft through a third sealed bearing. A support frame 28 is fixedly connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com