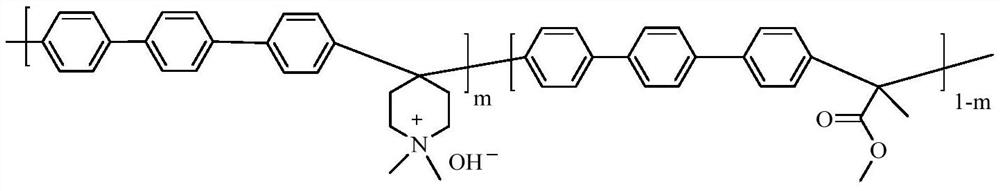

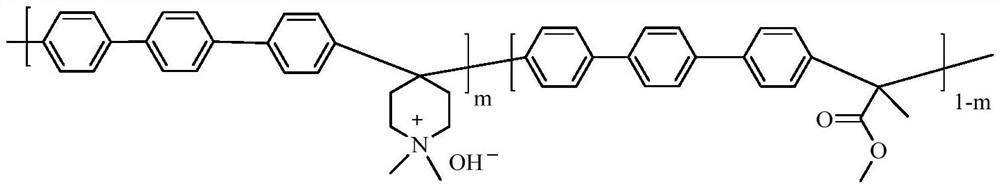

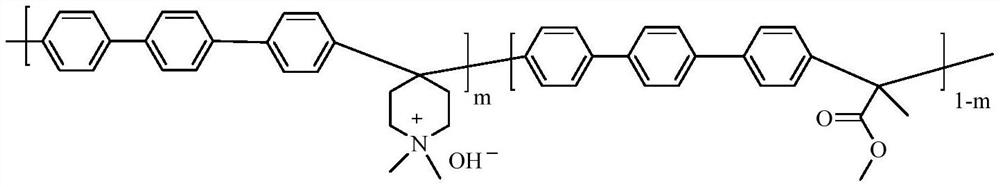

Piperidine type anion exchange membrane for alkaline electrolytic tank and preparation method thereof

An anion-exchange membrane and electrolytic cell technology, applied in the field of piperidine-type anion-exchange membrane and its preparation, can solve the problems of poor dimensional stability, high water absorption swelling, low ion conductivity, etc., and achieve the effect of fewer reaction steps and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Synthesis of piperidine-type three-monomer polymer: 1.41g (6mmol) of p-terphenyl was added to a 25mL three-necked flask, then 8mL of dichloromethane solution was added, followed by 0.6928g (6mmol) of N-methyl-4-piper Pyridone and 56 μL (0.6 mmol) of methyl pyruvate, after mechanical stirring for a period of time, slowly add 1 mL (9.98 mmol) of trifluoroacetic acid and 5 mL (56.5 mmol) of trifluoromethanesulfonic acid under ice bath conditions, and then the temperature of the reaction system rises gradually to room temperature. When the reaction solution became highly viscous, the reaction solution was poured into methanol to precipitate a crude polymer, then washed with potassium carbonate solution until neutral, and vacuum-dried at 60°C for 24 hours to obtain a three-monomer polymer material.

[0035] Preparation of quaternized anion-exchange membrane: Weigh 1g (3.08mmol) of the three-monomer polymer material and add it to a 50mL one-port bottle, then add 20mL DMSO, di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com