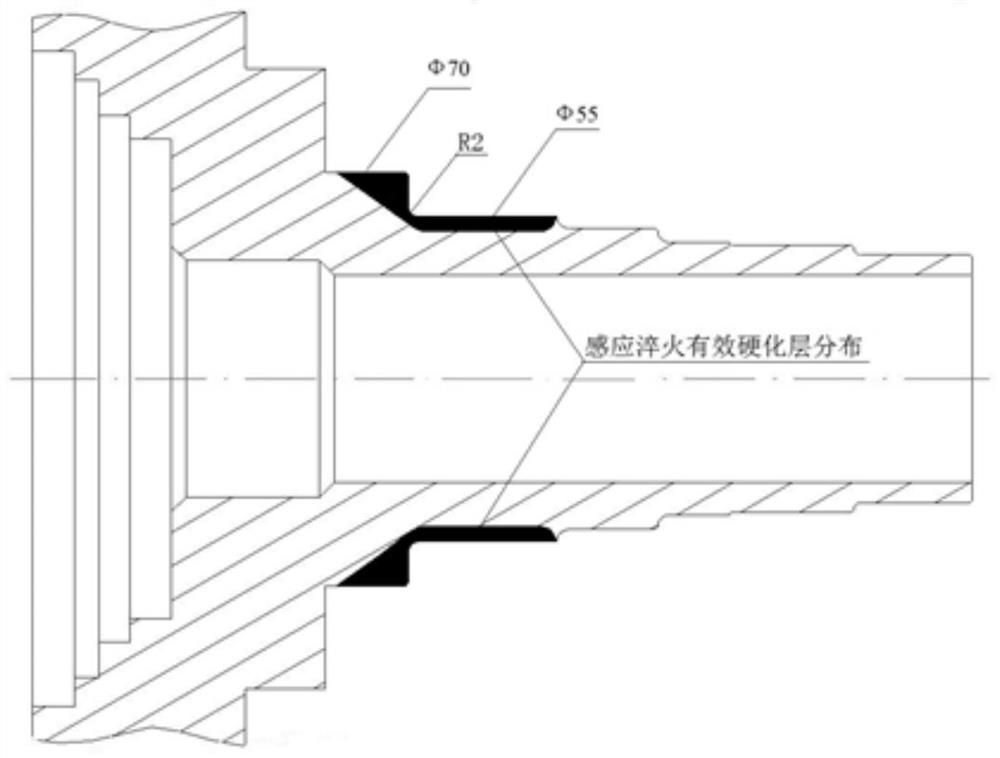

Hollow stepped shaft double-journal and transition fillet simultaneous quenching inductor and quenching method

A quenching sensor and transition fillet technology, which is applied in the field of auto parts processing, can solve the problem that the two journals cannot be heated evenly, and achieve the effects of avoiding melting, preventing tempering, and reducing heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

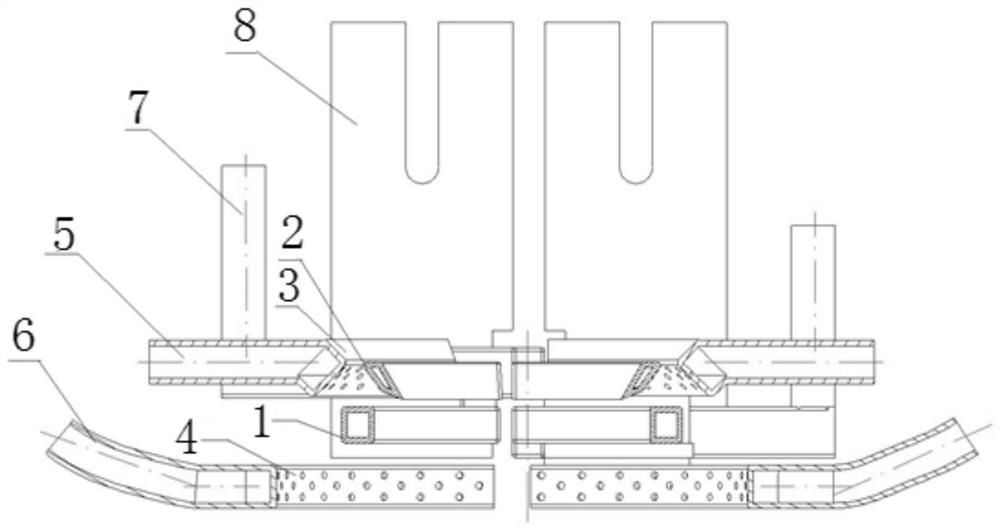

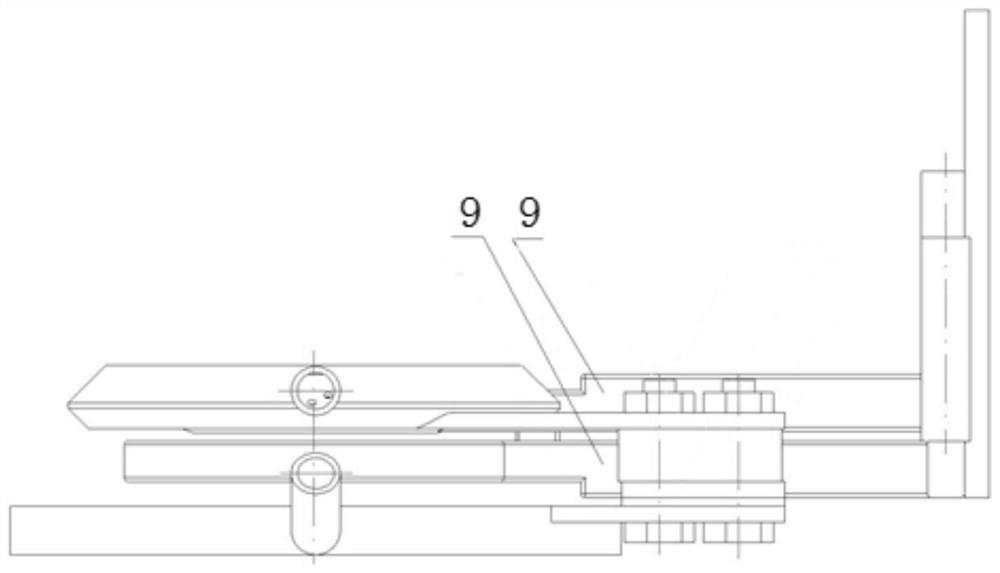

[0060] Such as Figure 2-Figure 6 As shown, the double journal of the hollow stepped shaft and the simultaneous quenching inductor of the transition fillet of the present invention include: the first annular effective ring 1 with a rectangular cross-section made of a 10X9X1.5 copper tube, and the short-circuit tube made of a 10X9X1.5 copper tube 18. Use 12X6X1.5 copper tubes to remake the second-shaped effective circle with an approximate parallelogram cross-section. 2. Two confluence tubes 9 and two transition tubes made of 12X10X1.5 copper tubes. 17. Use Ф 12X1.5 copper tubes for control The completed sensor cooling water pipe joint 7, two left and right symmetrical contact plates made of 5 mm thick copper plate 8, the water spray ring fixing plate made of 5 mm thick copper plate 14 The inductor composed of copper brazing conducts electricity Circuit: use 14X9X1.5 copper tube to remake the first ring-shaped quenching water spray ring with a rectangular cross-section and a 30...

Embodiment 2

[0072] Step 1: Put the part to be processed with the balance weight and place the journal part upwards on the fixture at the lower top of the machine tool, press the start button, and the part to be processed will start to rotate;

[0073] Step 2: After the part rotates for 3 seconds, the sensor moves to the static preheating position at a speed of 3000mm / min, heats for 2 seconds, stops heating for 3 seconds, reheats for 1 second, and moves to the rounded corner static heating position at a speed of 160mm / min ;

[0074] Step 3: Heating at the rounded corner for 7 seconds, spraying water while the sensor quickly moves up 10mm at a speed of 5000mm / min to the second static heating position, and heating for 1 second;

[0075] Step 4: The sensor moves to the end position of the quenching zone at a speed of 200mm / min, stops heating, and at the same time, the sensor quickly moves up 10mm at a speed of 5000mm / min to the static water spray position, sprays water for 30 seconds, stops t...

Embodiment 3

[0078] Step 1: Put the part to be processed with the balance weight and place the journal part upwards on the fixture at the lower top of the machine tool, press the start button, and the part to be processed will start to rotate;

[0079] Step 2: After the part rotates for 3 seconds, the sensor moves to the static preheating position at a speed of 3000mm / min, heats for 1.8 seconds, stops heating for 2 seconds, reheats for 1.2 seconds, and moves to the rounded corner static heating position at a speed of 180mm / min ;

[0080] Step 3: Heating at the rounded corner for 8 seconds, while spraying water, the sensor quickly moves up 12mm at a speed of 5000mm / min to the second static heating position, and heating for 1.2 seconds;

[0081] Step 4: The sensor moves to the end position of the quenching zone at a speed of 180mm / min, and stops heating. At the same time, the sensor moves rapidly upwards at a speed of 5000mm / min by 12mm to the static water spray position, and sprays water fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com