Veneer door plate and preparation method thereof

A door panel and veneer technology, which is applied in the field of veneer door panels and its preparation, can solve the problems of uneven coating of adhesive glue, shortening the service life of veneer door panels, and easy misalignment between panels, so as to increase recognition and aesthetics , Improve the scope of application, good clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of this veneer door panel body is:

[0046] Step 1: Take two wooden boards, use cutting equipment to cut the two wooden boards into square boards of the same specification, and then polish the two wooden boards smoothly through the grinding equipment, one of which is used as a bearing board, and the other is used as a texture board;

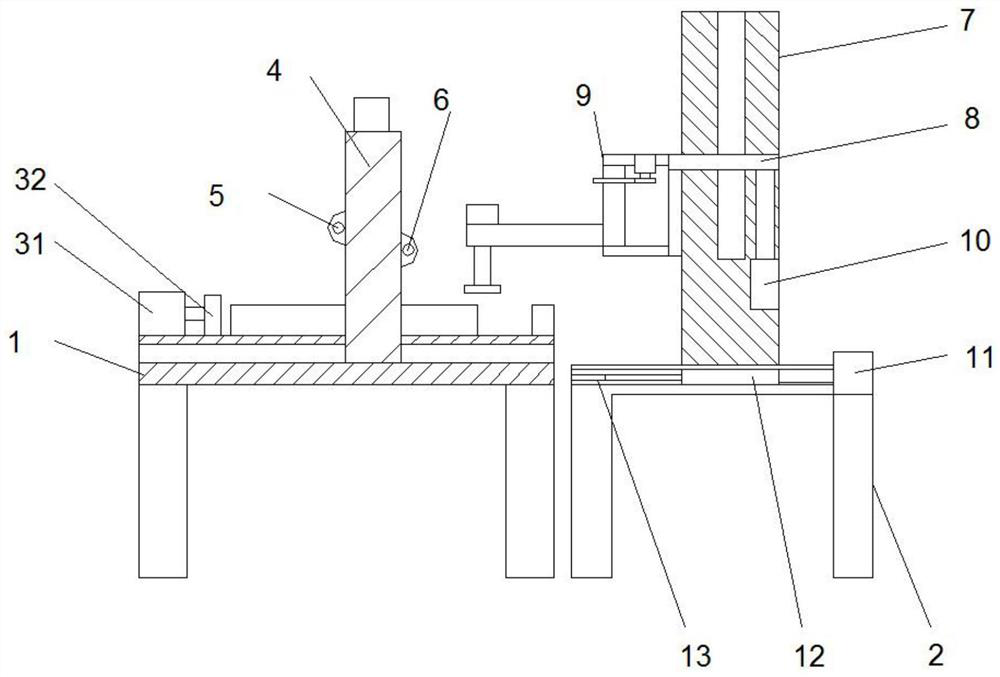

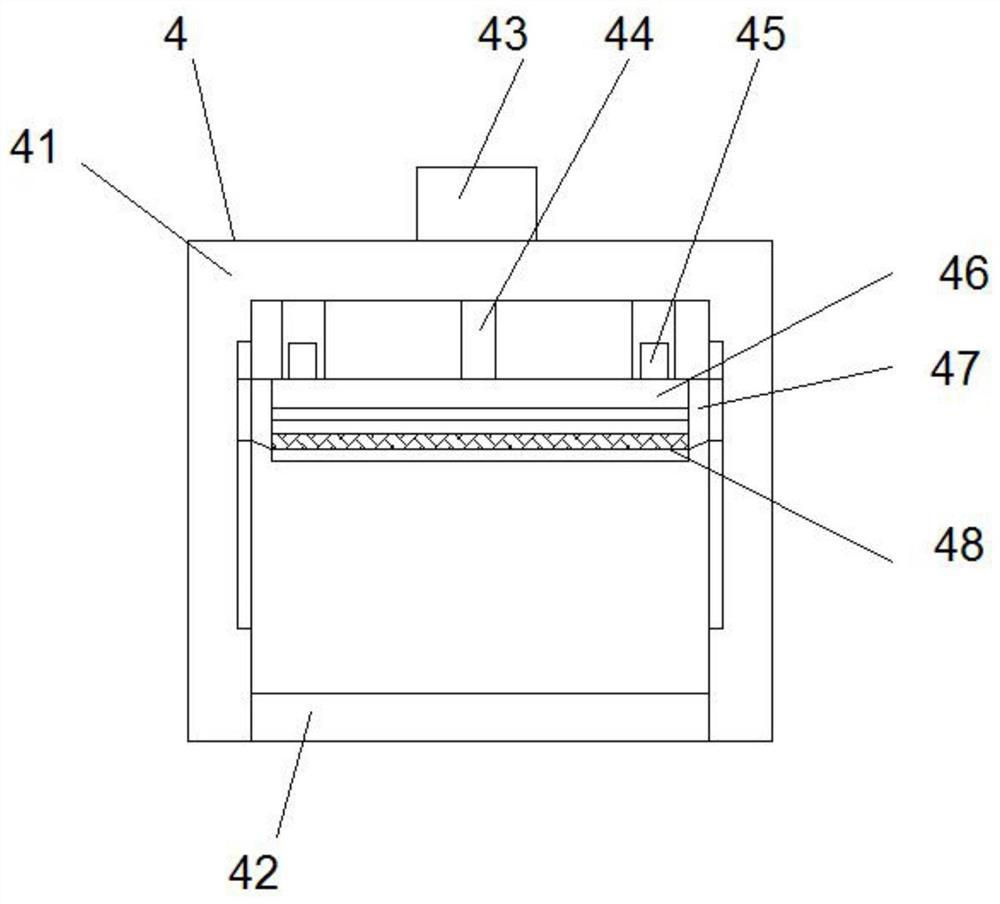

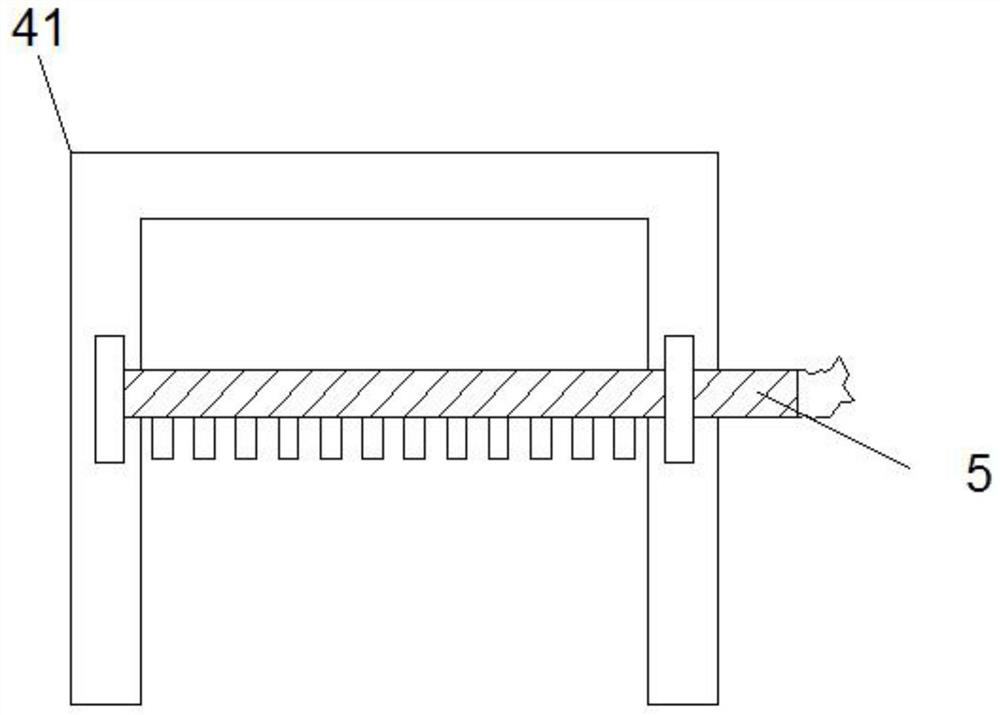

[0047] Step 2: Put the load-bearing plate and texture plate into the pressing equipment for pressing, first place the load-bearing plate in the fixing mechanism set on the upper surface of the bottom plate 1, start the electric telescopic rod 111 to drive the clamping block 112 to move horizontally, so that Drive the connecting plate 42 to move horizontally, and then drive the pressing mechanism 4 to move horizontally until the blowing pipe 5 blows off all the sawdust on the upper surface of the bearing plate, and then abut one side of the bearing plate with the plug plate 35 , one end of the load bearing plate abuts...

Embodiment 1

[0062] The rear end of the blowing pipe 5 is connected with a conduit, the end of the conduit away from the blowing pipe 5 is connected with a fan, the rear end of the rubber hose 6 is connected with a hose, and the end of the hose far away from the rubber hose 6 is connected with the glue outlet of the glue machine, the fixing frame The two ends of the two 91 are respectively welded and fixed with two T-shaped plates 8, and the cross-section of the uniform liquid block 97 is square. In the fixing mechanism provided on the upper surface of the bottom plate 1, start the electric telescopic rod 111 to drive the block 112 to move horizontally, thereby driving the connecting plate 142 to move horizontally, and then driving the pressing mechanism 4 to move horizontally until the blowing pipe 5 pushes the upper surface of the bearing plate All the sawdust is blown off, and then one side of the load-bearing plate is abutted against the plug-in plate 1 35, and one end of the load-beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com