Cleaning-heat treatment coupling technology for high-concentration petroleum-contaminated soil

A technology for oil pollution and polluted soil, which is applied in the field of cleaning-heat treatment coupling process, can solve problems such as difficulty in meeting the target needs of practitioners, and achieve the effects of reducing the coefficient of variation, saving costs, and reducing pollution loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

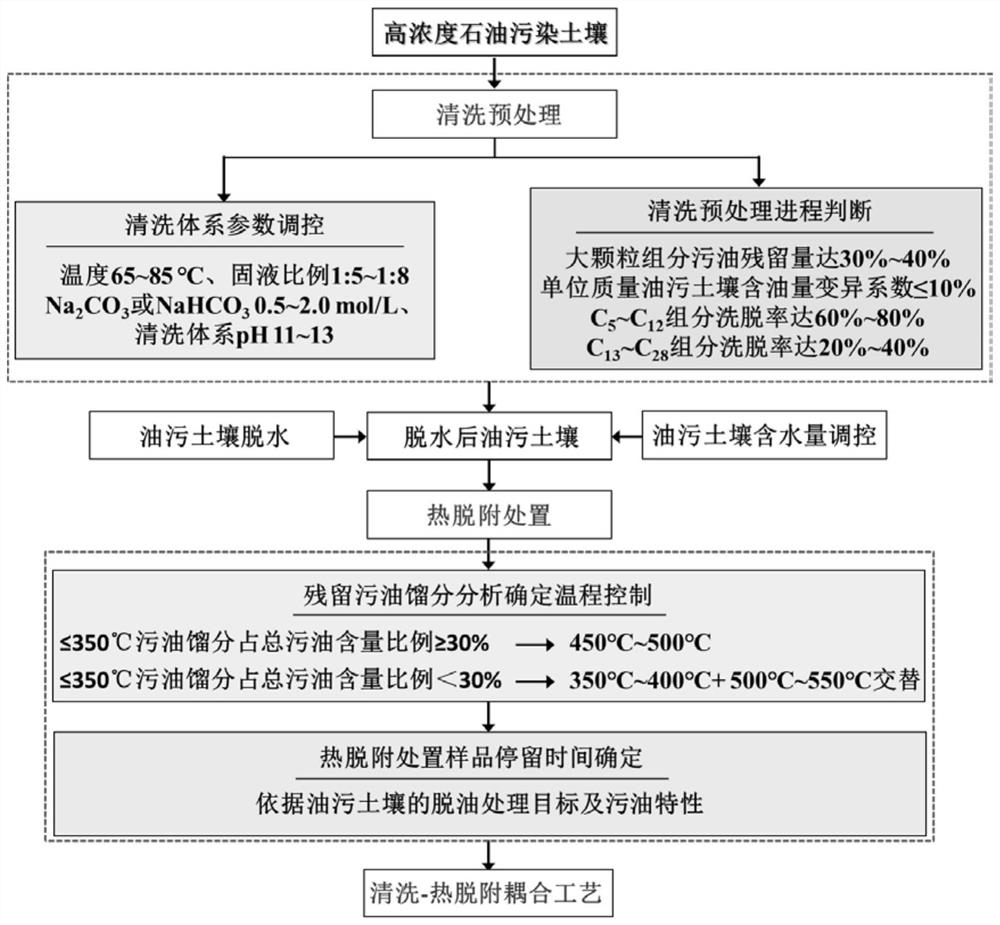

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Cleaning and pretreatment of high-concentration petroleum-contaminated soil in the oilfield area

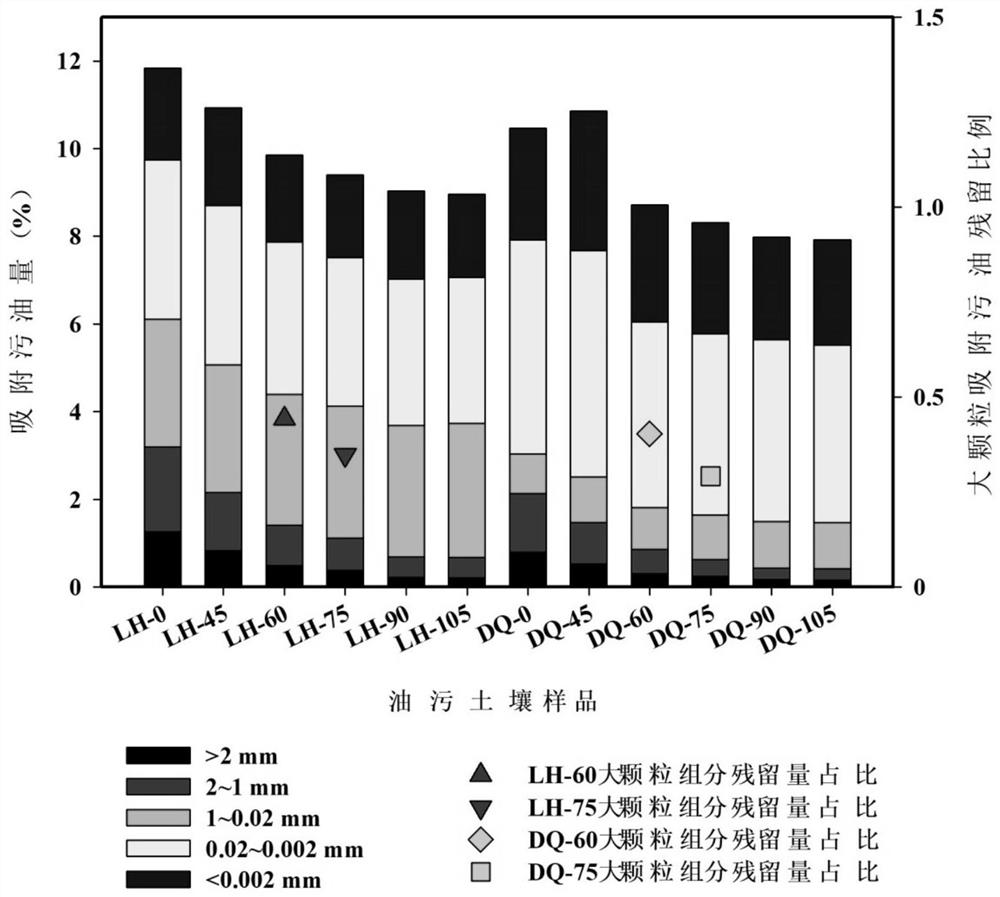

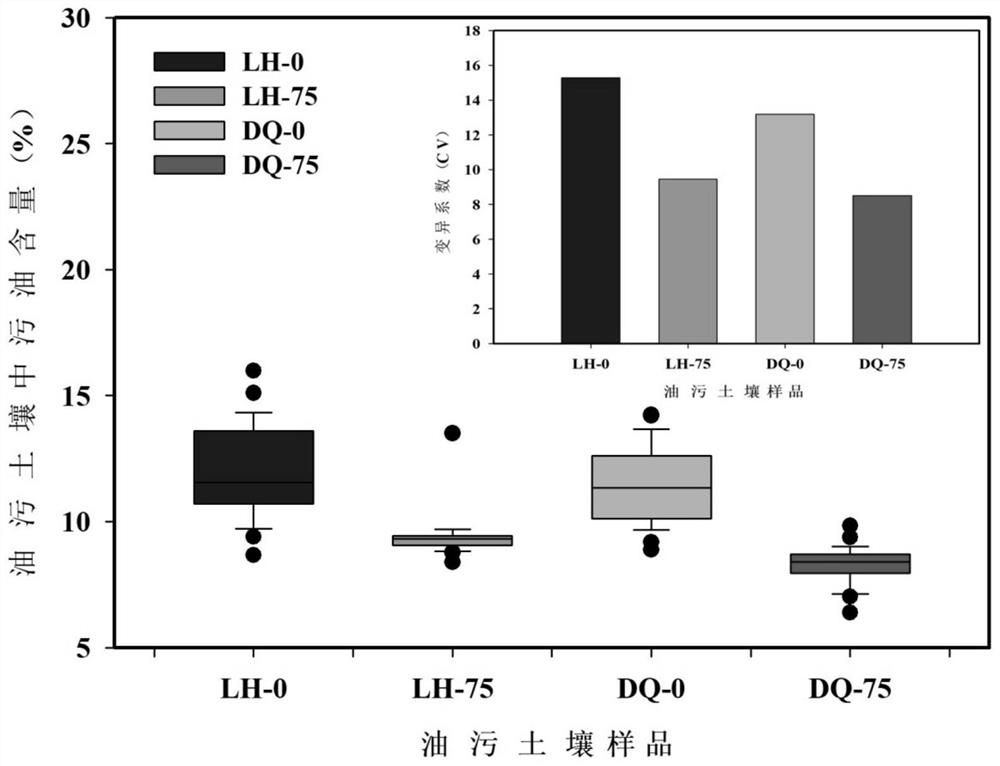

[0041] The objects to be disposed of are high-concentration oil-contaminated soils from Liaohe Oilfield (LH) and Daqing Oilfield (DQ). The contaminated soils are cleaned and pretreated after impurity removal and crushing. The parameters of oil-contaminated soil are analyzed in Table 1. The total amount of dirty oil contained in the soil is repeatedly sampled and measured, and the average values of the dirty oil content calculated by statistical analysis are 11.84% and 10.47% (that is, the oil-containing g number per 100g of soil), and the coefficient of variation of the dirty oil content of each sample Respectively reached 15.29% and 13.19%. Extracting and analyzing the group components of the dirty oil samples showed that the contents of saturated hydrocarbons, aromatic hydrocarbons and non-hydrocarbons in the LH dirty oil samples were 6.11%, 1.52%, and 4.22%, ...

Embodiment 2

[0053] Example 2 Cleaning-heat treatment coupled treatment of high-concentration petroleum-contaminated soil in oilfield areas

[0054] The cleaned and pretreated high-concentration petroleum-contaminated soils in the Liaohe Oilfield and Daqing Oilfield were subjected to wet screening and dehydration treatment to separate large particle components with a particle size > 1 mm. The remaining soil samples were set to different degrees of dehydration, namely After dehydration, the water content in the oily soil is 0%, 5%, 8%, 12%, 15% and 20%, respectively, and thermal desorption treatment is carried out. The temperature range of thermal desorption treatment is 450 ℃ ~ 550 ℃, and the desorption residence time is 55min, the desorption result is as follows Figure 5 Shown, wherein, the thermal desorption polluted oil removal rate of the LH and DQ oil-contaminated soils with a water content of 8% all reaches the maximum value, showing that for the two kinds of oil-contaminated soil s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com