A kind of production method of high pressure resistant sheet-shaped tantalum powder

A production method and high-voltage-resistant technology, used in transportation and packaging, electrolytic capacitors, capacitors, etc., can solve the problems of low breakdown voltage, poor voltage resistance and reliability, and achieve high breakdown voltage, good burn resistance, short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

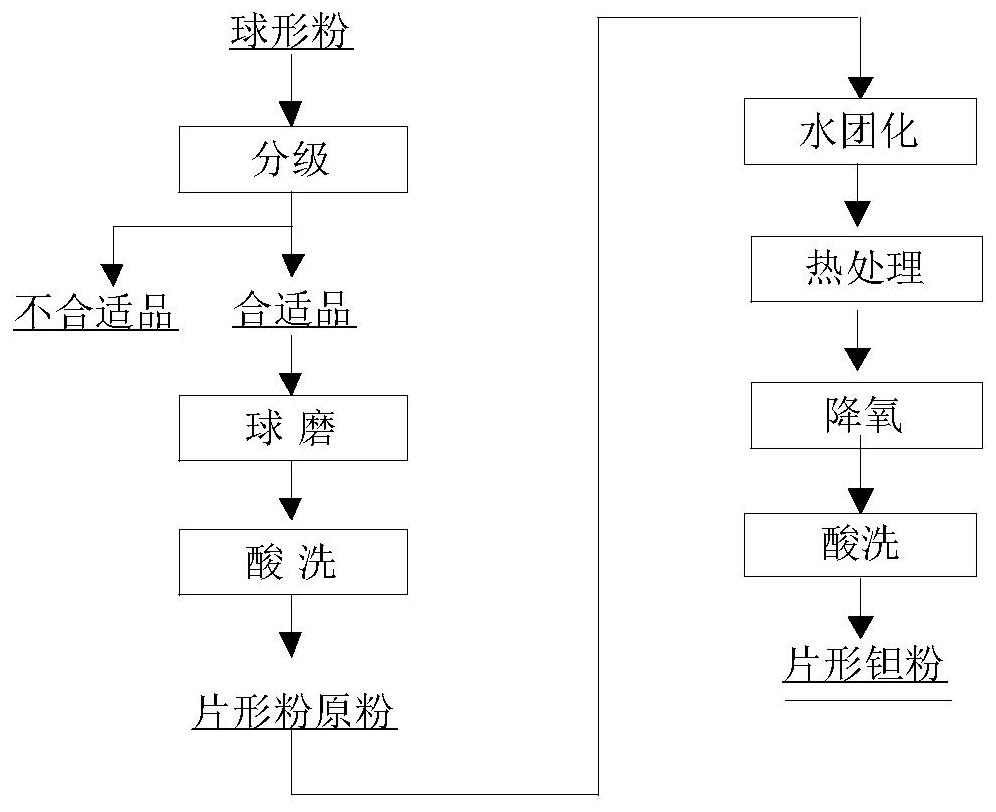

Method used

Image

Examples

Embodiment 1

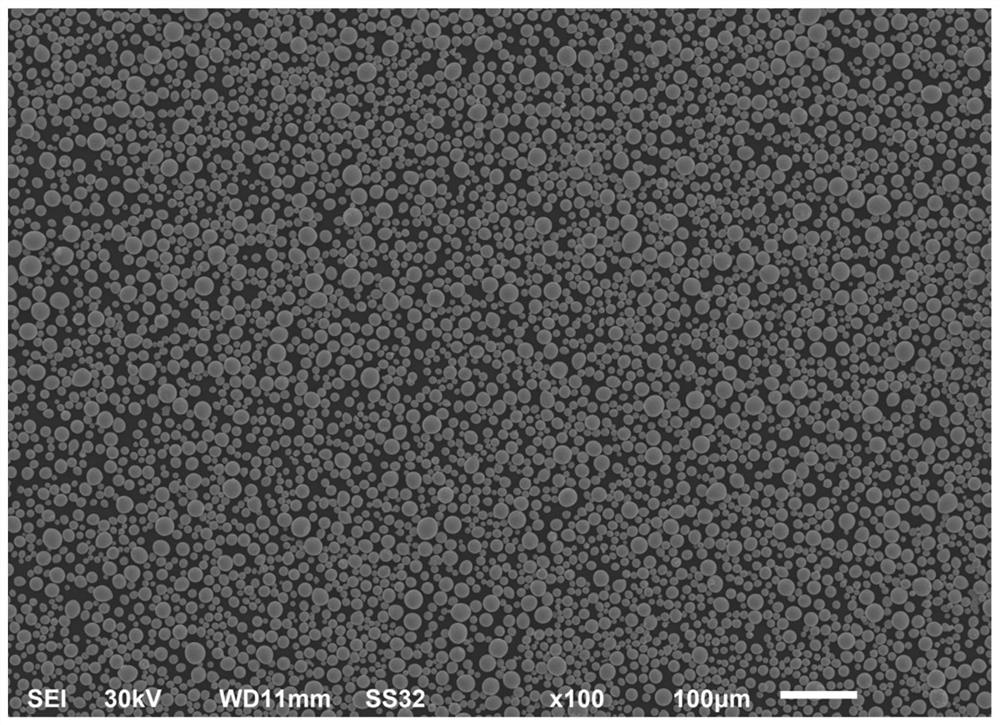

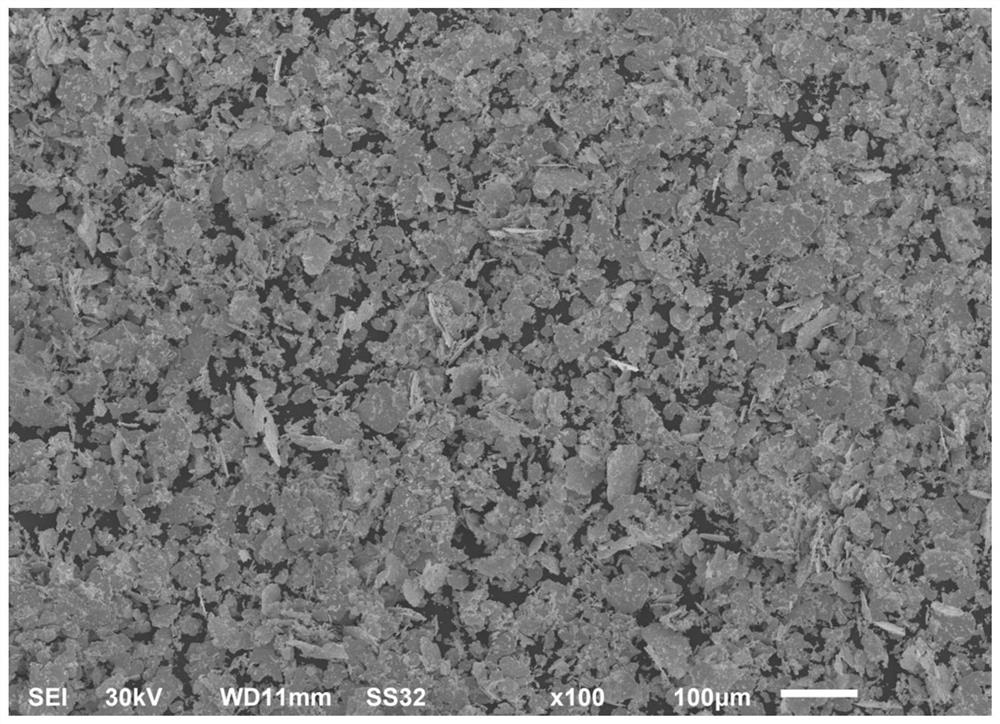

[0040] Use atomized spherical tantalum powder, see SEM figure 2 , wet sieve 1200 mesh, take the undersieve, and carry out planetary ball milling after the classified powder is dried, with analytical pure anhydrous ethanol as the ball milling medium, ball milling time 60min, ball milling ball material ratio is 5:1, ball milling speed is 100r / min. Ball milled powder with HNO 3 and HF mixed acid (concentration of 69% HNO 3 Solution, HF solution with a concentration of 40% is prepared by adding water, HNO 3 Solution, HF solution and water (volume ratio is 20:1:60) pickling to remove metal impurities, drying and sieving to obtain sheet-shaped raw powder. The physical properties and chemical impurity content of the flake-shaped raw powder are shown in Table 1, and SEM is shown in image 3 .

[0041] The above-mentioned sheet-shaped raw powder is subjected to water agglomeration granulation, and the amount of agglomerated water is 18%. After the dough is formed, it is dried a...

Embodiment 2

[0049] Select atomized spherical tantalum powder, wet sieve 1500 mesh, take the undersieve, and carry out planetary ball milling after the classified powder is dried, with analytical pure anhydrous ethanol as the ball milling medium, ball milling time is 180min, and the ball-to-material ratio of ball milling is 4: 1. The ball milling speed is 100r / min. Ball milled powder with HNO 3 and HF mixed acid (concentration of 69% HNO 3 Solution, HF solution with a concentration of 40% is prepared by adding water, HNO 3 Solution, HF solution and water volume ratio is 20:1:60) pickling to remove metal impurities, drying and sieving to obtain sheet-shaped raw powder 2. The physical properties and chemical impurity content of the sheet-shaped raw powder are shown in Table 3.

[0050] The above-mentioned sheet-shaped raw powder is subjected to water agglomeration granulation, and the amount of agglomerated water is 18%. After the dough is formed, it is dried and sieved. at 10 -3 Heate...

Embodiment 3

[0057] Select atomized spherical tantalum powder, wet sieve 1000 mesh, take the undersieve, and carry out planetary ball milling after the classified powder is dried, with analytical pure anhydrous ethanol as the ball milling medium, ball milling time is 30min, and the ball-to-material ratio of ball milling is 8: 1. The ball milling speed is 100r / min. Ball milled powder with HNO 3 and HF mixed acid (concentration of 69% HNO 3 Solution, HF solution with a concentration of 40% is prepared by adding water, HNO 3 Solution, HF solution and water (volume ratio is 20:1:60) pickling to remove metal impurities, drying and sieving to obtain sheet-shaped raw powder 3. The physical properties and chemical impurity content of the sheet-shaped raw powder are shown in Table 5.

[0058] The above-mentioned sheet-shaped raw powder is subjected to water agglomeration granulation, and the amount of agglomerated water is 18%. After the dough is formed, it is dried and sieved. at 10 -3 Heate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown voltage | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com