Coiled tubing plate-plate butt welding equipment and welding method

A welding equipment and welding method technology, applied in welding equipment, plasma welding equipment, welding/welding/cutting items, etc., can solve the problems of beveling of steel strips, difficult to original steel strips, limited welding thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

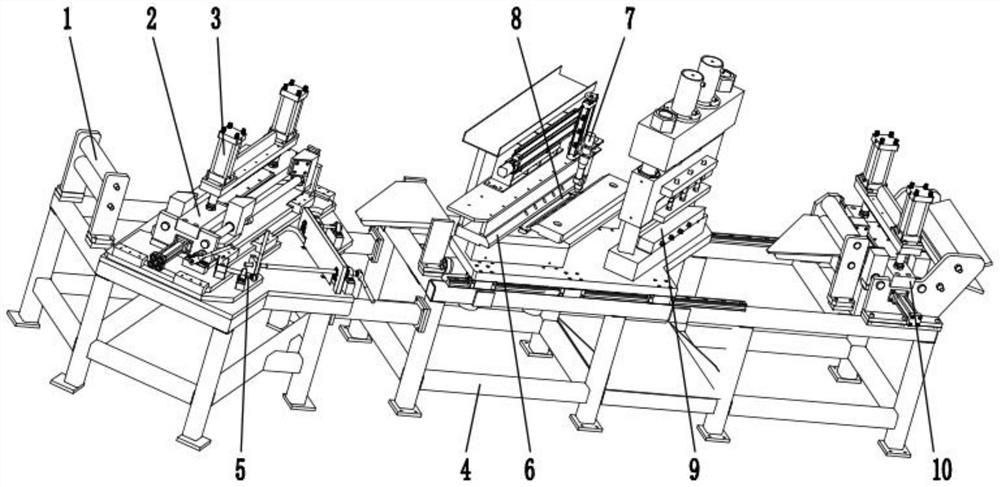

[0025] like figure 1 As shown, a coiled tubing plate-to-plate butt welding equipment includes a bracket 4 and a steel strip straightening wheel 1, a steel strip position adjustment device 2, and a steel strip welding clamping device that are sequentially arranged on the support 4 from left to right 6. Plasma torch 7, steel strip cutting device 9 and steel strip clamping device 10, said steel strip position adjusting device 2 is provided with adjusting steel strip position knob 5 and air pressure driving device 3, said adjusting steel strip position knob 5 The position of the steel belt can be adjusted, and the pneumatic driving device 3 can push and compress the steel belt after being pressurized.

[0026] When the coiled tubing plate-to-plate butt welding equipment and welding method of the present embodiment 1 are in use, first a steel strip is put into the steel strip cutting device 9 through the steel strip clamping device 10, and the steel strip is paired by the steel str...

Embodiment 2

[0038] A coiled tubing plate butt welding method, comprising the following steps:

[0039] Step 1, first put a steel strip into the steel strip cutting device 9 through the steel strip clamping device 10, and fix the steel strip through the steel strip clamping device 10, and send the steel strip cut by the steel strip cutting device 9 into The bottom of the steel strip welding clamping device 6, and then another steel strip is put into the steel strip position adjustment device 2 through the steel strip straightening wheel 1, and then sent to the bottom of the steel strip welding clamping device 6. At this time, the steel strip can be adjusted The position knob 5 adjusts the position of the steel belt, and after the position adjustment is completed, the steel belt is pressed by the pneumatic drive device 3 to fix it;

[0040] Step 2: Arrange the arc starting plate and the arc extinguishing plate at both ends of the steel strip, and press and fix the ends of the two steel stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com