High-performance concrete admixture and preparation method thereof

A high-performance concrete and admixture technology, which is applied in the directions of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of complex preparation method and poor effect of improving concrete performance, and achieves simple preparation process, The effect of large surface energy and good dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

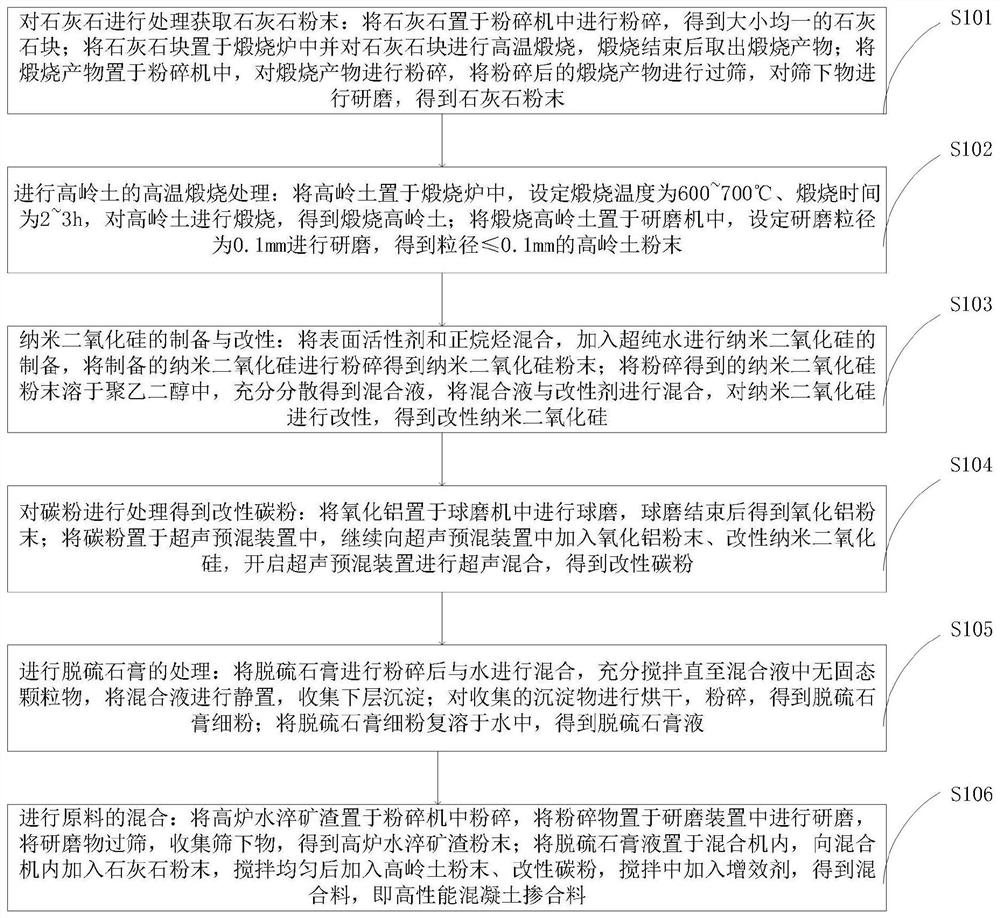

[0042] like figure 1 Shown, the preparation method of the high-performance concrete admixture that the embodiment of the present invention provides comprises the following steps:

[0043] S101, processing the limestone to obtain limestone powder: placing the limestone in a pulverizer for crushing to obtain limestone blocks of uniform size; placing the limestone block in a calciner and calcining the limestone block at high temperature, and taking out the calcined product after the calcining; placing the calcined product in a pulverizer, pulverizing the calcined product, sieving the pulverized calcined product, and grinding the undersieve to obtain limestone powder;

[0044] S102, perform high-temperature calcination treatment of kaolin: put kaolin in a calcination furnace, set the calcination temperature to 600-700° C., and calcination time to 2-3 hours, and calcine the kaolin to obtain calcined kaolin; place the calcined kaolin in a grinder , set the grinding particle size to 0...

Embodiment 1

[0077] Put 6 parts of blast furnace water-quenched slag in a pulverizer for crushing, put the crushed material in a grinding device for grinding, sieve the ground material, collect the under-sieve, and obtain blast furnace water-quenched slag powder; put 4 parts of desulfurization gypsum liquid in In the mixer, add 9 parts of limestone powder into the mixer, stir evenly, add 5 parts of kaolin powder and modified carbon powder modified by 1 part of carbon powder, 2 parts of alumina and 1 part of nano-silica, stirring Add 2 parts of synergist to obtain the mixture, that is, the high-performance concrete admixture.

Embodiment 2

[0079] Put 8 parts of blast furnace water-quenched slag in a pulverizer for crushing, put the crushed material in a grinding device for grinding, sieve the ground material, collect the under-sieve, and obtain blast furnace water-quenched slag powder; put 4 parts of desulfurization gypsum liquid in In the mixer, add 12 parts of limestone powder into the mixer, stir evenly, add 6 parts of kaolin powder and modified carbon powder modified by 2 parts of carbon powder, 3 parts of alumina and 1 part of nano-silica, and stir Add 2 parts of synergist to obtain the mixture, that is, the high-performance concrete admixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com