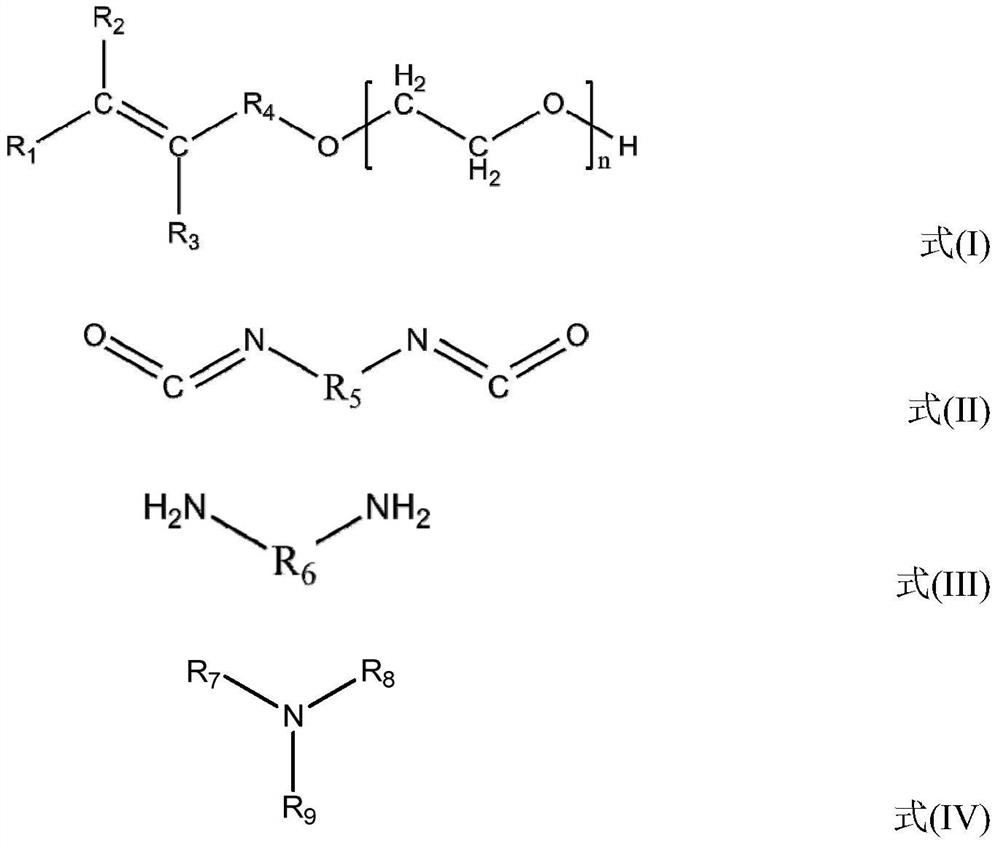

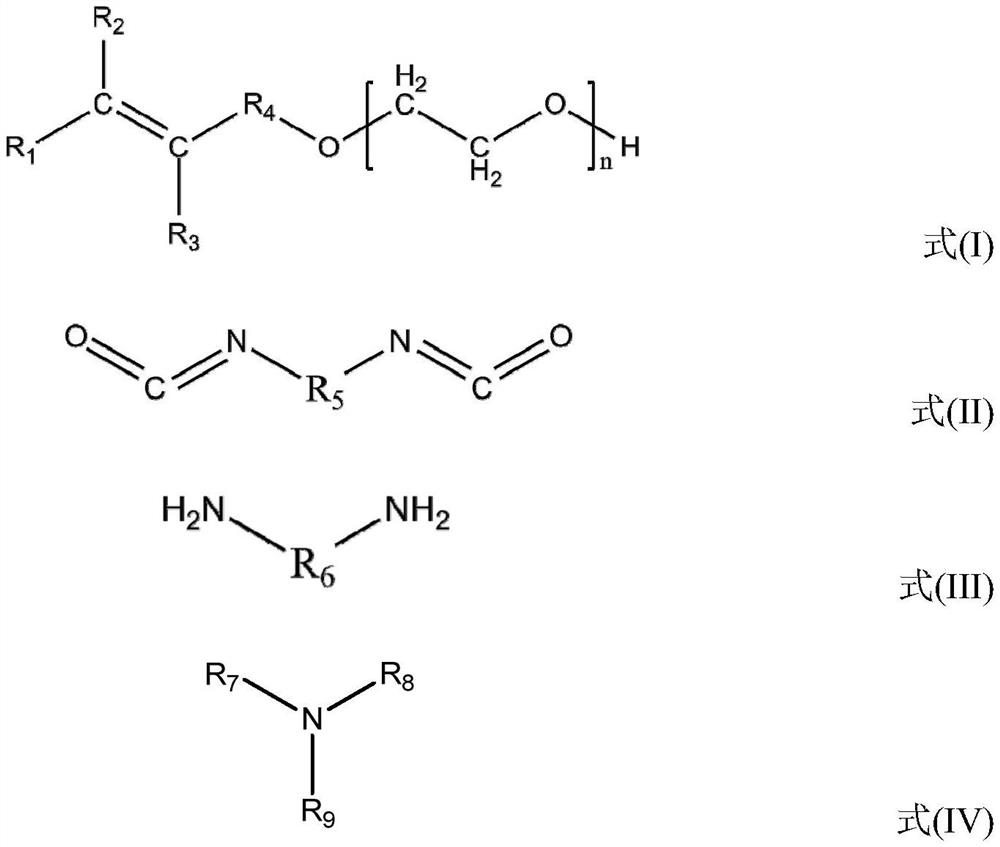

Unsaturated amino polyoxyethylene ether and polycarboxylate superplasticizer as well as synthesis method and application thereof

A technology of amino polyoxyethylene ether and polyoxyethylene ether, which is applied in the field of building material admixtures and can solve problems such as poor product stability and complex production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

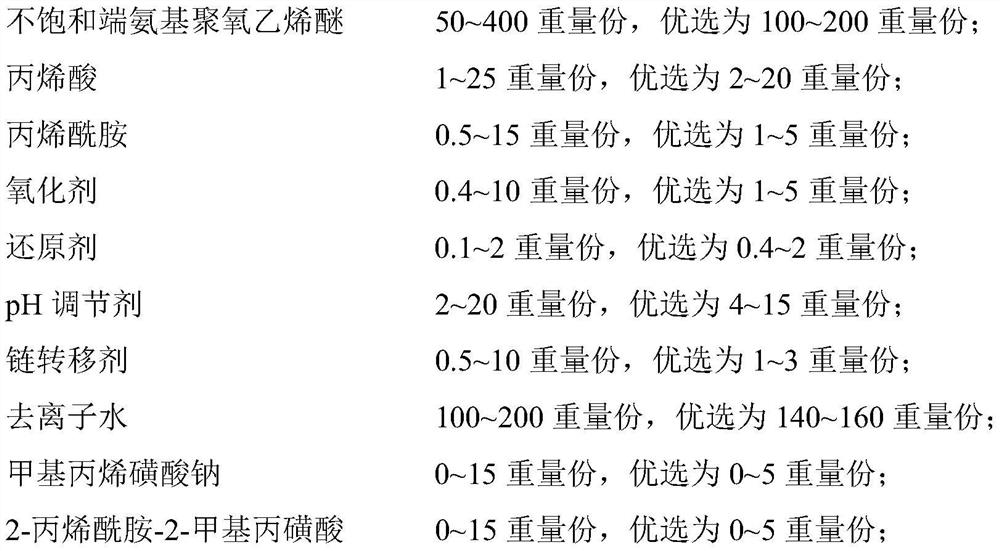

Method used

Image

Examples

Embodiment 1

[0080] (1) Heat and melt 1000 g of HPEG with a molecular weight of 2000, vacuum dehydrate at 120° C. for 2 hours, and cool to 60° C. to obtain molten unsaturated polyoxyethylene ether;

[0081] (2) Add 111.2g of isophorone diisocyanate to the molten unsaturated polyoxyethylene ether obtained in step (1) according to a molar ratio of 1:1, take HPEG as a benchmark, add 0.05% by weight of dibutyltin dilaurate, heat up to 75°C, react for 2 hours, measure the NCO content to the theoretical value, the theoretical value is 1.89% by weight, and then cool down to room temperature;

[0082] (3) The reaction product obtained in step (2) was added dropwise to 85.2 g of isophorone diamine, and after the dropwise addition was completed, the reaction was continued for 1 h to obtain unsaturated amino polyoxyethylene ether.

Embodiment 2

[0084] Example 2 is basically the same as Example 1, except that HPEG is replaced by isopentenol polyoxyethylene ether (TPEG, molecular weight 2400), and isophoronediamine is replaced by diphenylmethanediamine , replacing isophorone diisocyanate with toluene diisocyanate, and the molar ratio of prenol polyoxyethylene ether (1200g), toluene diisocyanate, and diphenylmethanediamine is 1:1:1.2.

Embodiment 3

[0086] Example 3 is basically the same as Example 1, except that the molar ratio of HPEG (1000 g), isophorone diisocyanate, and isophorone diamine is 1:1:0.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com