Preparation method and application of blocky raw wheat koji for brewing food

A raw wheat koji and block technology, which is applied in the preparation of vinegar, alcoholic beverages, food science and other directions, can solve the problems of large storage area of koji, affecting the aroma components of fermented products, and restricting the production of raw wheat koji, etc. Achieve the effect of improving production efficiency, avoiding season-dependent problems, and inhibiting the growth of miscellaneous bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The design of embodiment 1 stacking frame

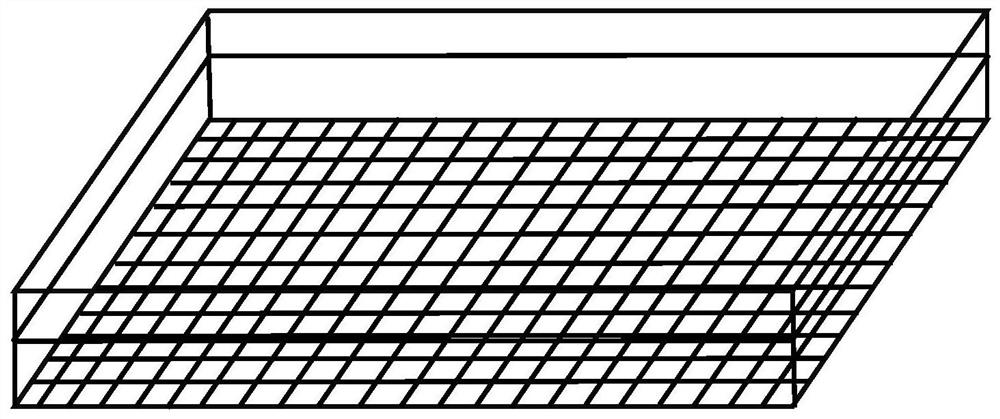

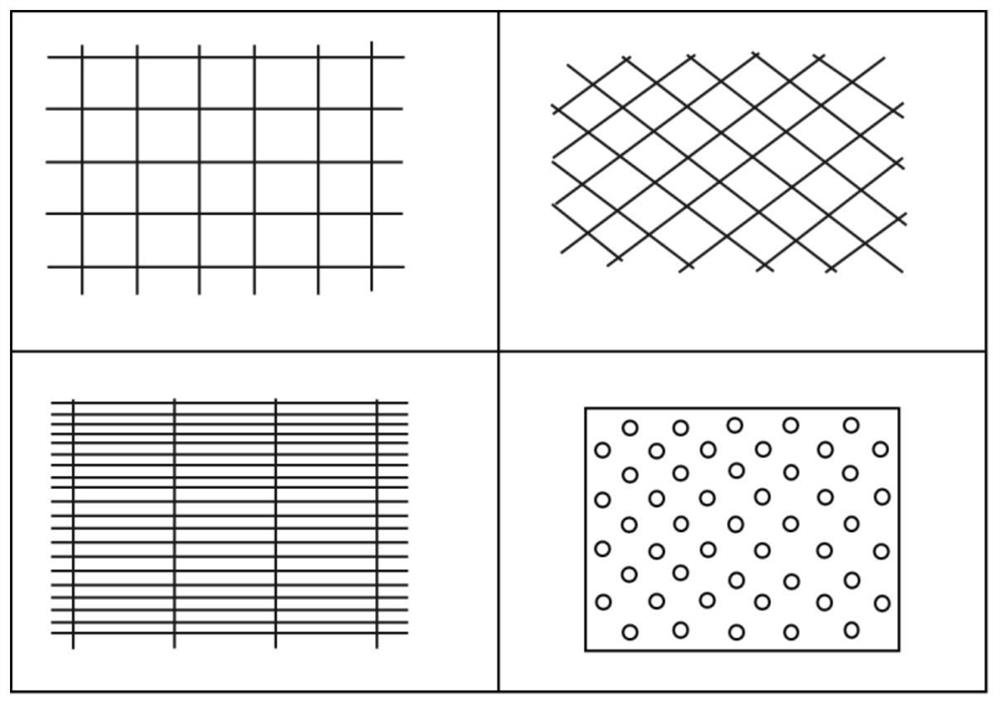

[0047] Such as Figure 1~4 As shown, the stacking frame is uncapped at the top, and has a cubic shape with air holes on the bottom and side walls. The material of the stacking frame is steel wire or steel sheet. When steel wire is used to make the stacking frame, follow the figure 2 Construct the basic unit, and then follow the figure 1 The basic unit is pressed into a cuboid-shaped stacking frame according to a fixed size, and the formed stacking frame can meet the requirements of load-bearing and good ventilation at the same time; when the material of the stacking frame is steel sheet, ventilation performance is given priority, so each square The number of rice round holes must exceed 350.

[0048] When in use, the cuboid koji pieces pressed by the koji making machine are placed in the air hole stacking frame. The design of the air hole stacking frame is helpful for the heat and moisture removal of the curved blocks, whi...

Embodiment 2

[0050] The production process flowchart of embodiment 2 self-heating mechanical block bent

[0051] Such as Figure 5 As shown, the production process of the self-heating mechanical bent block is:

[0052] (1) Raw material processing: select the soft wheat grains produced in the current year to make wheat koji, and the wheat grains should be kept dry and sieved before use;

[0053] (2) Put the screened wheat grains into the hopper of the wheat rolling machine, set the roller spacing of the roller machine to adjust the suitable discharge granularity, and each grain of wheat is crushed into 2-8 wheat grains; After crushing, put it into a koji mixer and add water with 12-25% of the wheat mass, and stir to make the wheat granules absorb water evenly, so as to ensure that no starch lumps and water masses are produced;

[0054] (3) the loose groat after moistening is made into a compact cuboid of 20-30cm long, 10-15cm wide and 6-15cm high by a koji making machine;

[0055] (4) Le...

Embodiment 3

[0057] Embodiment 3 The production technology of self-heating mechanical block bent

[0058] After sieving, 50kg of red skin or yellow skin soft wheat produced in the same year will be pulverized, and the water content of the wheat will be 13% (± 1.5%). When pulverizing, pay attention to that the rollers of the roller machine should be set to discharge the crushed wheat grains. 4 ± 2 granules, add 10-12kg of clear water to the koji mixer to obtain a wet material, and pay special attention not to produce white heart water blocks formed by starch agglomerates absorbing water.

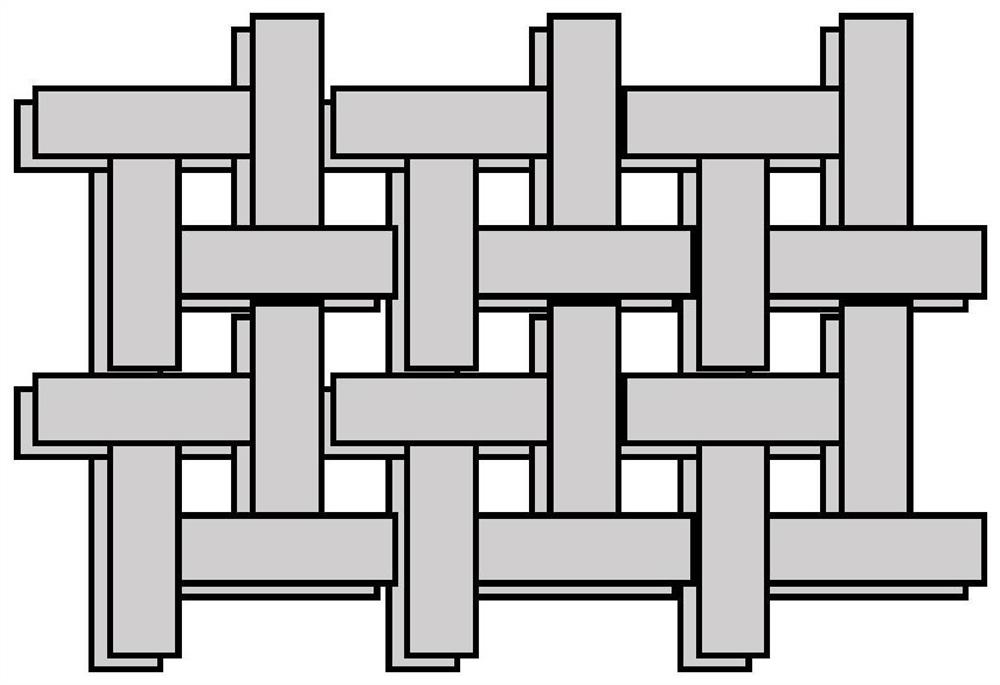

[0059] A mechanical bending machine is used to press a specific shape of the curved block, the length of the curved block is 28 (± 1) cm, the width is 18 (± 1) cm, and the height is 8 (± 1) cm. After putting the pressed pieces in the transfer area for 20 minutes, use an automatic palletizer to place the pieces in a T-shape or a T-shape according to the adjacent pieces in the layer, and place the pieces in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com