Metal carbon nanotube composite film modified by porous polymer and its preparation method and application

A carbon nanotube composite, porous polymer technology, used in chemical instruments and methods, membrane technology, water pollutants, etc., can solve problems such as affecting the growth of aquatic organisms and microorganisms, reducing water transparency, and affecting human health, etc. Effects of suitability for dye separation, enhanced stability and durability, large application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 The preparation of a porous polymer-modified metal-carbon nanotube composite membrane, the specific steps are as follows:

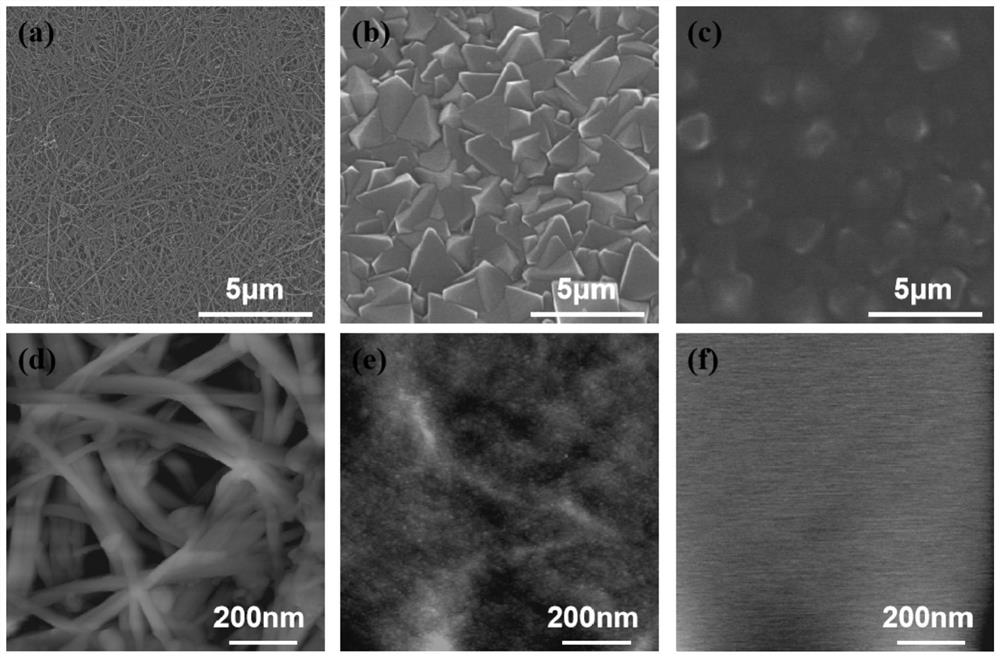

[0022] (1) Synthesis of modified multi-walled carbon nanotube (MWCNT) films. First, 30 ml of concentrated hydrochloric acid and 10 ml of concentrated nitric acid were prepared into aqua regia at a volume ratio of 3:1, and the existing MWCNT film was placed in it and soaked at 50 °C for 6 hours for acidification. Then, the acidified MWCNT film Wash with ultrapure water and dry;

[0023] Accurately weigh 0.112 g of zirconium tetrachloride and 0.087 g of terephthalic acid, dissolve them in 60 ml of N,N-dimethylformamide (DMF), then sonicate for 20 minutes, and subsequently, add 8.3 Milliliter of acetic acid to obtain the mixture, then transfer the mixture and acidified dried MWCNT film (10*10 cm2) into a 100 ml stainless steel autoclave, heat at 120 °C for 24 hours; after natural cooling, wash with DMF and methanol, Finally, dry at 60 degr...

Embodiment 2

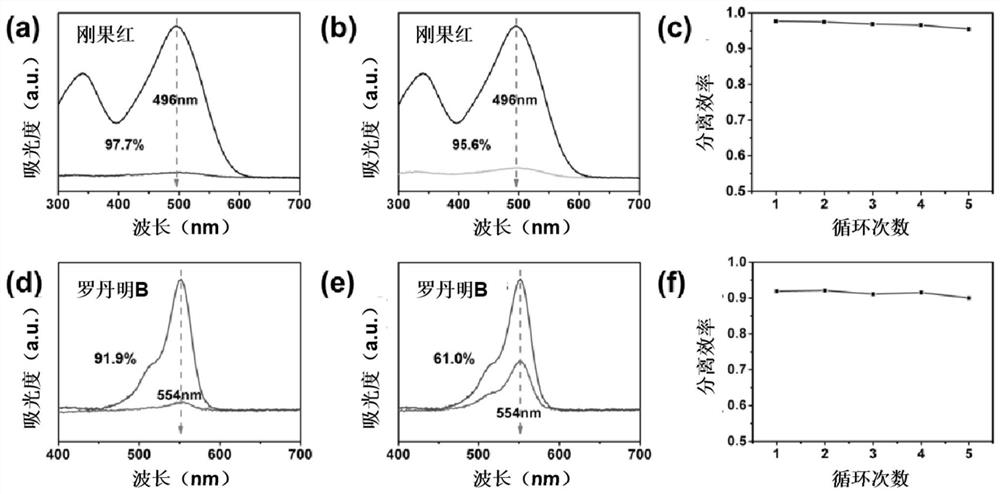

[0030] Example 2 Comparative test of the dye separation effect of the metal-loaded modified MWCNT membrane before and after modifying the porous polymer

[0031] attached figure 2 Separation experiments of two single-component dye solutions were carried out to compare the separation effects of membranes before and after coating with porous polymers; figure 2 Among them, a is the separation efficiency of Congo red by the composite membrane modified with porous polymer, b is the separation efficiency of Congo red by the modified MWCNT membrane loaded with metal, and c is the separation efficiency of Congo red solution by the composite membrane modified with porous polymer. Cycle separation efficiency, d is the separation efficiency of rhodamine B by the composite membrane modified with porous polymer, e is the separation efficiency of rhodamine B by the modified MWCNT membrane loaded with metal, f is the separation efficiency of rhodamine B by the composite membrane modified w...

Embodiment 3

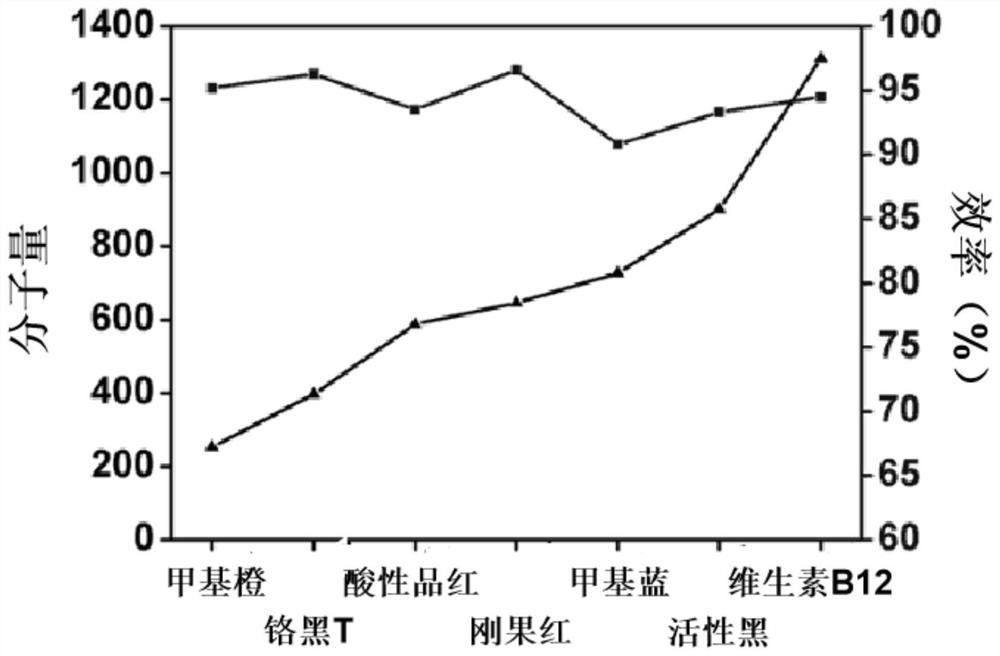

[0040] Example 3 Dye Separation Performance Test of Composite Membrane Modified with Porous Polymer

[0041] The separation efficiency of the composite membrane for dyes with different molecular weights was tested. The results show that the separation efficiency of the membrane for various dyes with a molecular weight of 200 to 1300 is above 90%, which indicates that the separation performance of the composite membrane has wide applicability. In addition, chrome black T was selected as the dye for testing the cycle performance of the membrane. After 10 cycles, the separation efficiency of Chrome Black T decreased from 98% to 96%, and the separation flux remained at 40 L m -2 the s -1 MPa -1 Above, it is shown that composite membranes modified with porous polymers can effectively perform a variety of separation operations.

[0042] attached image 3 is the separation efficiency of dyes with different molecular weights; Figure 4 is the recirculation separation efficienc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com