Method for separating dye-containing wastewater based on porous polymer-modified metal carbon nanotube composite membrane

A carbon nanotube composite and porous polymer technology, which is applied in semipermeable membrane separation, chemical instruments and methods, and textile industrial wastewater treatment, can solve the problems of poor separation effect and insufficient separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

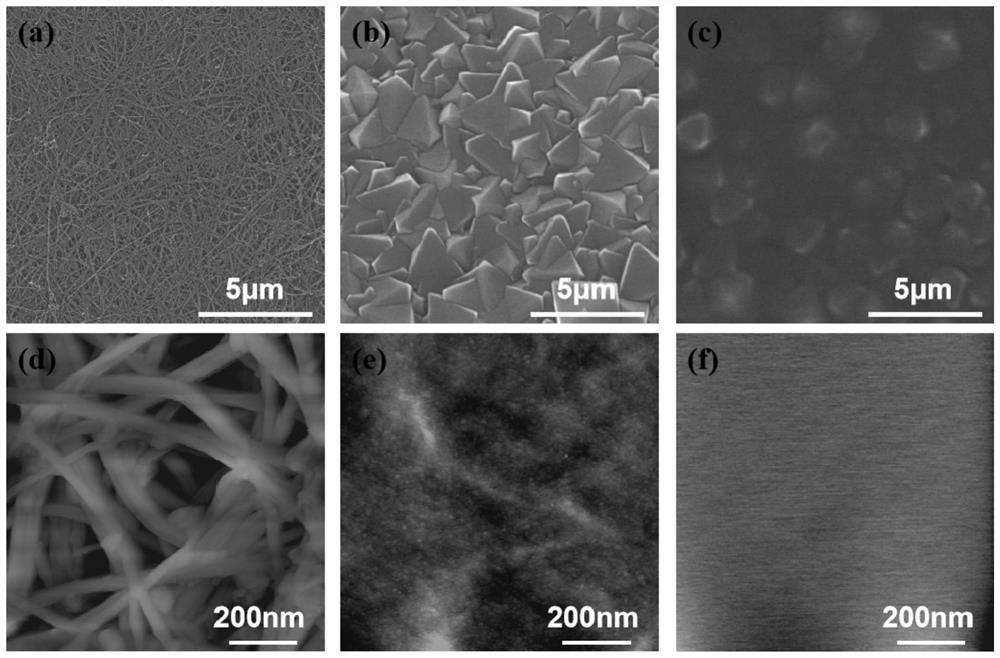

[0028] Preparation example The preparation of porous polymer-modified metal carbon nanotube composite film, the specific steps are as follows:

[0029] (1) Synthesis of modified multi-walled carbon nanotube (MWCNT) films. First, 30 ml of concentrated hydrochloric acid and 10 ml of concentrated nitric acid were prepared into aqua regia at a volume ratio of 3:1, and the existing MWCNT film was placed in it and soaked at 50 °C for 6 hours for acidification. Then, the acidified MWCNT film Wash with ultrapure water and dry;

[0030] Accurately weigh 0.112 g of zirconium tetrachloride and 0.087 g of terephthalic acid, dissolve them in 60 ml of N,N-dimethylformamide (DMF), then sonicate for 20 minutes, and subsequently, add 8.3 Milliliter of acetic acid to obtain the mixture, then transfer the mixture and acidified dried MWCNT film (10*10 cm2) into a 100 ml stainless steel autoclave, heat at 120 °C for 24 hours; after natural cooling, wash with DMF and methanol, Finally, dry at 60 ...

Embodiment 1

[0038]The Congo red aqueous solution with a concentration of 100ppm is introduced into the high-pressure stirring tank of the filter equipment, and argon gas is introduced to pressurize to 3.0 bar (bar). Under the action of pressure, the separation of dye-containing wastewater is completed; the filter membrane is loaded with Metal modified MWCNT membranes or composite membranes modified with porous polymers.

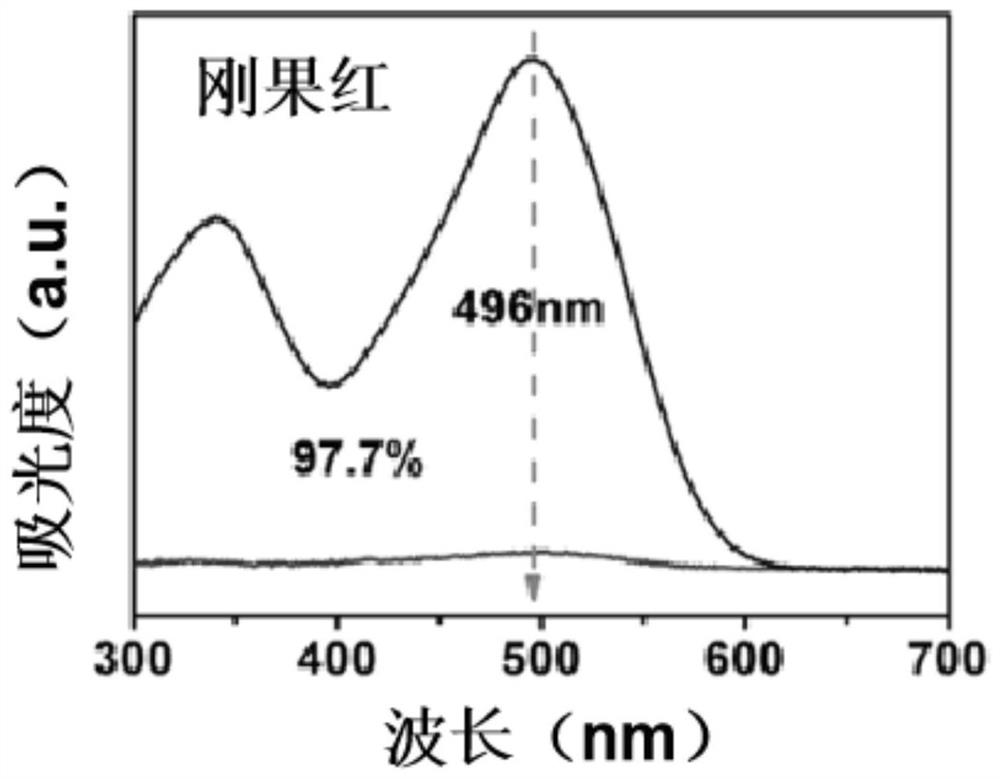

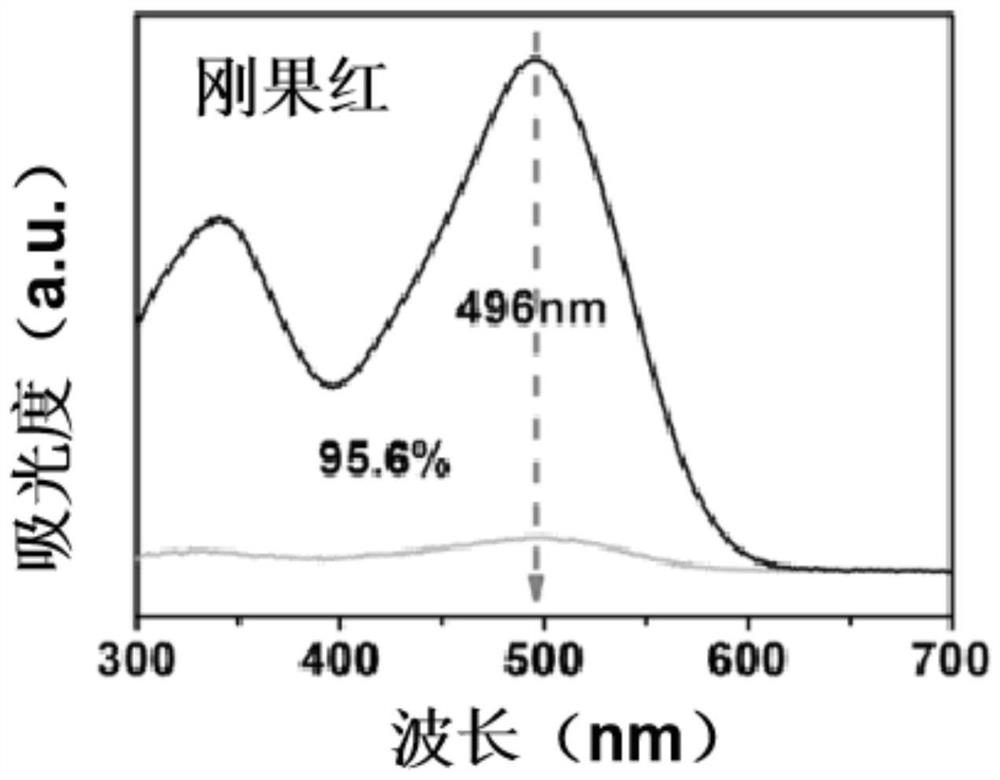

[0039] See attached figure 2 , the separation efficiency of the composite membrane modified with porous polymer was 97.7% (Congo red); see attached image 3 , the separation efficiency of the metal-loaded modified MWCNT membrane was 95.6% (Congo red).

[0040] At the same time, the circular separation effect on the dye solution was tested. After the first separation, it was washed with water, dried and then separated again; see attached Figure 4 , after 5 cycles, the separation efficiency of Congo red by the composite membrane modified with porous polymer can be kept...

Embodiment 2

[0042] The rhodamine B aqueous solution with a concentration of 100ppm is introduced into the high-pressure stirring tank of the filter equipment, and argon is introduced to pressurize to 3.0 bar (bar). Under the action of pressure, the separation of dye-containing wastewater is completed; the filter membrane is the load Metal-modified MWCNT membranes or composite membranes modified with porous polymers.

[0043] See attached Figure 5 , the separation efficiency of the composite membrane modified with porous polymer was 91.9% (rhodamine B), see attached Figure 6 , the separation efficiency of the modified MWCNT membrane loaded with metal is 61.0% (rhodamine B), and the separation efficiency of the composite membrane can be significantly improved;

[0044] At the same time, the circular separation effect on the dye solution was tested. After the first separation, it was washed with water, dried and then separated again; see attached Figure 7 , after 5 cycles, the separatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com