Oil-soluble heavy oil viscosity reducer and preparation method thereof

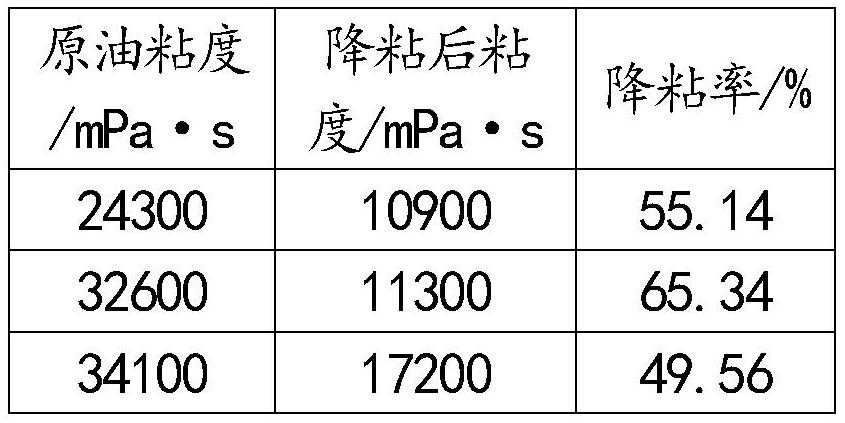

A heavy oil viscosity reducer and oil-soluble technology, applied in the field of oil-soluble heavy oil viscosity reducer and its preparation, can solve the problems of poor universality, insufficient oil solubility, insignificant viscosity reduction effect, etc. The effect of significant viscosity reduction and good universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

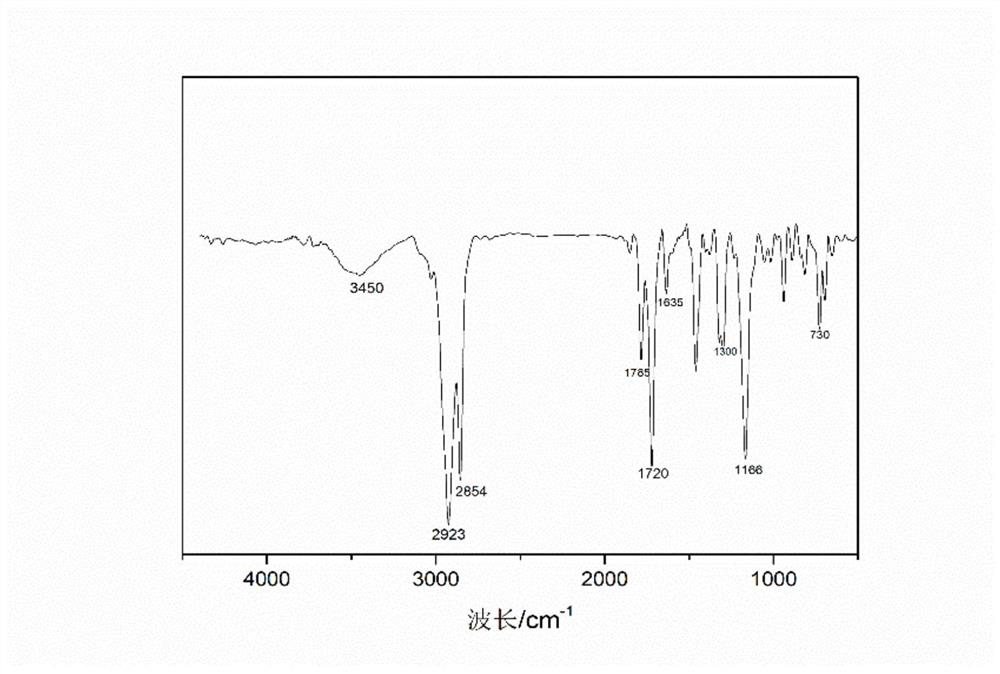

Image

Examples

preparation example Construction

[0026] The present invention also provides a preparation method of an oil-soluble heavy oil viscosity reducer, comprising: mixing 2,2,3,3-tetrafluoropropyl methacrylate, styrene, maleic anhydride and formaldehyde according to the molar ratio Stearyl acrylate is mixed, dissolved and heated to initiate a reaction to obtain an oil-soluble thick oil viscosity reducer.

[0027] Preferably, the molar ratio is: 2,2,3,3-tetrafluoropropyl methacrylate:styrene:maleic anhydride:octadecyl methacrylate=1:3:2:10.

[0028] Preferably, the solvent selected in the dissolution process is toluene, and the mass of the toluene is 90%-110% of the mass sum of the four monomers. Compared with other solvents, this solvent is less toxic and will not affect the progress of the reaction.

[0029] Preferably, the heating temperature in the heating process is 60°C-80°C.

[0030] Preferably, the initiator for initiating the reaction is benzoyl peroxide, and the mass of the benzoyl peroxide is 1%-2% of the...

Embodiment 1

[0036] The molar ratio of the reaction monomers is: 2,2,3,3-tetrafluoropropyl methacrylate: styrene: maleic anhydride: octadecyl methacrylate is 1:2:1:9.

[0037] The preparation process is: add 0.2g of 2,2,3,3-tetrafluoropropyl methacrylate, 0.22g of styrene, 0.1g of The octadecyl methacrylate of maleic anhydride and 3.05g, add the toluene of 1.57g again as solvent, when stirring while heating in oil bath until temperature is 60 ℃, 0.714g benzoyl peroxide is dissolved in 2 g of toluene was added dropwise into a three-necked flask to initiate the reaction. After 5 hours of reaction, the heating was stopped, and the above reaction solution was rotary evaporated under vacuum conditions to remove the solvent toluene to obtain an oil-soluble heavy oil viscosity reducer.

Embodiment 2

[0039] The molar ratio of the reaction monomers is: 2,2,3,3-tetrafluoropropyl methacrylate: styrene: maleic anhydride: octadecyl methacrylate is 1:4:3:11.

[0040] The preparation process is: add 0.2g of 2,2,3,3-tetrafluoropropyl methacrylate, 0.44g of styrene, 0.3g of The octadecyl methacrylate of maleic anhydride and 3.72g, add the toluene of 2.66g again as solvent, when stirring while heating in oil bath until the temperature is 60 ℃, 0.0932g benzoyl peroxide is dissolved in 2 g of toluene was added dropwise into a three-necked flask to initiate the reaction. After 5 hours of reaction, the heating was stopped, and the above reaction solution was rotary evaporated under vacuum conditions to remove the solvent toluene to obtain an oil-soluble heavy oil viscosity reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com