Preparation method of high-performance stable PPA and SBS composite modified asphalt

A composite modified asphalt, stabilized technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of limited performance improvement and inability to meet the needs of use, so as to improve temperature sensing performance, increase softening point, and reduce high temperature Effect of Viscosity and High Temperature Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

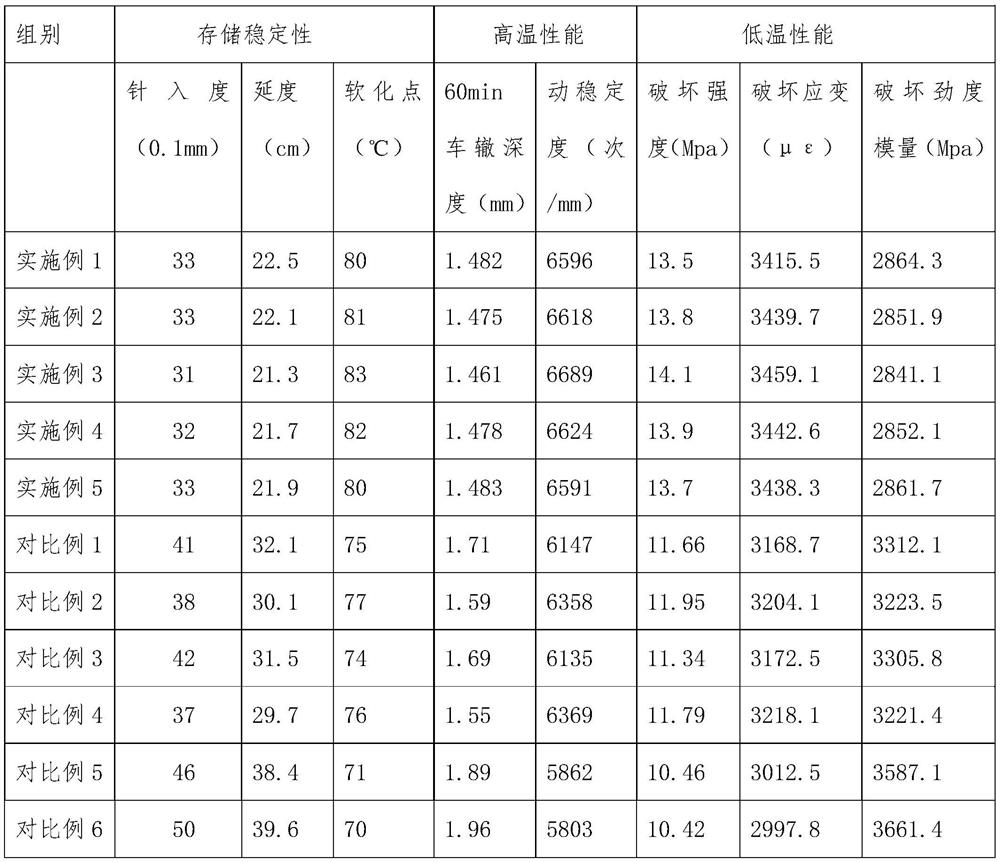

Examples

Embodiment 1

[0027] In the embodiment of the present invention, a high-performance stable PPA and SBS composite modified asphalt preparation method, the steps are as follows:

[0028] Prepare the following raw materials in parts by weight: 60 parts of base asphalt, 40 parts of natural asphalt, 30 parts of vegetable asphalt, 50 parts of waste tire rubber powder, 20 parts of thermoplastic elastomer, 10 parts of modified calcium carbonate, and 6 parts of modified sulfur , 10 parts of modified starch, 2 parts of organic acid, 4 parts of modified paraffin, 1 part of hydroxypropyl methylcellulose, 1 part of antioxidant, 3 parts of solubilizer, 2 parts of stabilizer, 1 part of PPA polyphosphoric acid , 2 parts of SBS linear modifier, then heat the base asphalt to 140°C, put the natural asphalt and plant asphalt into the base asphalt and stir for 40min to obtain the first mixture; send the first mixture into the shear tank, at 180 At a temperature of ℃, put the thermoplastic elastomer into the fir...

Embodiment 2

[0038] In the embodiment of the present invention, a high-performance stable PPA and SBS composite modified asphalt preparation method, the steps are as follows:

[0039] Prepare the following raw materials in parts by weight: 65 parts of base asphalt, 45 parts of natural asphalt, 32 parts of vegetable asphalt, 52 parts of waste tire rubber powder, 23 parts of thermoplastic elastomer, 12 parts of modified calcium carbonate, and 8 parts of modified sulfur , 12 parts of modified starch, 2.5 parts of organic acid, 6 parts of modified paraffin, 1.5 parts of hydroxypropyl methylcellulose, 1.5 parts of antioxidant, 4 parts of solubilizer, 3 parts of stabilizer, 1.5 parts of PPA polyphosphoric acid , 2.5 parts of SBS linear modifier, then heat the base asphalt to 145°C, put the natural asphalt and plant asphalt into the base asphalt and stir for 45min to obtain the first mixture; send the first mixture into the shear tank, at 185 At a temperature of ℃, put the thermoplastic elastomer...

Embodiment 3

[0049] In the embodiment of the present invention, a high-performance stable PPA and SBS composite modified asphalt preparation method, the steps are as follows:

[0050] Prepare the following raw materials in parts by weight: 70 parts of base asphalt, 50 parts of natural asphalt, 35 parts of plant asphalt, 55 parts of waste tire rubber powder, 25 parts of thermoplastic elastomer, 15 parts of modified calcium carbonate, and 9 parts of modified sulfur , 13 parts of modified starch, 3 parts of organic acid, 7 parts of modified paraffin, 2 parts of hydroxypropyl methylcellulose, 2 parts of antioxidant, 5 parts of solubilizer, 4 parts of stabilizer, 2 parts of PPA polyphosphoric acid , 3 parts of SBS linear modifier, then heat the base asphalt to 150°C, put the natural asphalt and plant asphalt into the base asphalt and stir for 50min to obtain the first mixture; send the first mixture into the shear tank, at 190 At a temperature of ℃, put the thermoplastic elastomer into the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com