Foamable cleaning composition

A technology of cleaning composition and composition, applied in the direction of high foaming composition, detergent composition, cleaning composition solvent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0133] Material

[0134] Alkoxylated anionic surfactant = SLES paste (70%): sodium lauryl ether sulfate (LES 702EO), available from Galaxy Surfactants

[0135] · Nonionic Surfactant = Ethoxylated Fatty Alcohol-C 12 EO 7 (100%) from Galaxy Surfactants, Tergitol 15-S-7 from Dow Chemicals

[0136] · Glycol Ether = Hexyl Carbitol, Hexyl Cellosolve, Di(Propylene Glycol) n-Butyl Ether, available from Dow Chemicals & Sigma Aldrich

[0137] Fatty acid esters = methyl laurate, ethyl laurate, ethyl caprylate, available from Sigma Aldrich

[0138] Chelating agent = Dequest 2010 (1-hydroxyethylidene-1,1-diphosphonic acid, HEDP, 59% solution): available from Thermphos, Switzerland

[0139] Citric acid (used as is) purchased from Merck India

[0140] · Sodium citrate dihydrate, purchased from Merck India

[0141] ·Deionized water

[0142] Control: Stain removal spray (commercially available sample, imported from Brazil)

[0143] Method for preparing the composition

[0144] Add e...

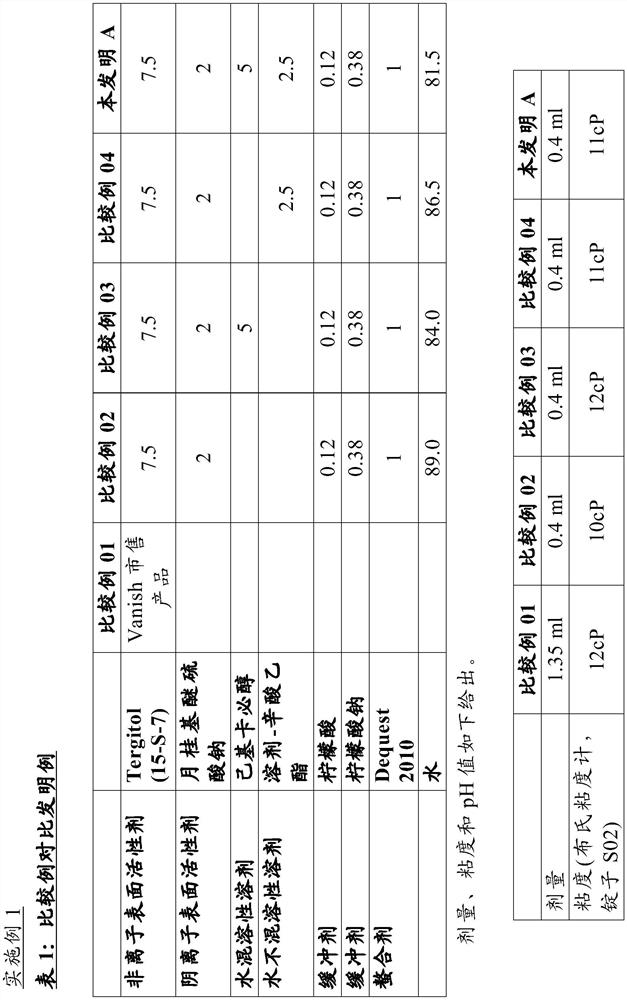

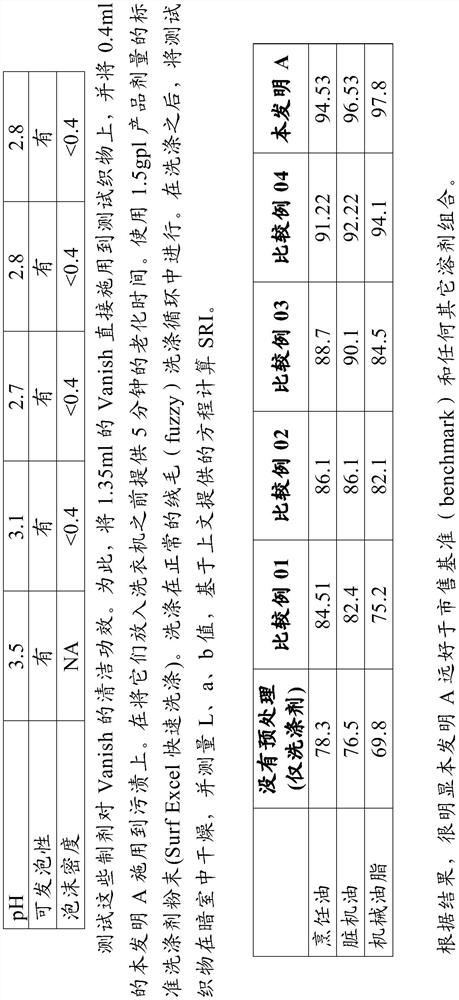

Embodiment 2

[0169] Example 2: Effect of pH

[0170] Foaming cleansing compositions were prepared based on the formulations shown in Table 2, and the pH of the resulting formulations were maintained at 2.5, 5 and 8 by adding buffers. The composition is sprayed onto the dyed fabric and after this treatment the pretreated fabric is washed according to the procedure described earlier herein. The results are summarized in the table below.

[0171] Table 2: Compositions under different pH conditions

[0172] The present invention A Comparative example 05 Comparative Example 06 Tergitol (15-S-7) 7.5 7.5 7.5 Sodium Lauryl Ether Sulfate 2 2 2 Hexyl Carbitol 5.0 5.0 5.0 Solvent - ethyl octanoate 2.5 2.5 2.5 citric acid 0.12 Sodium citrate 0.38 2.0 5.0 Dequest 2010 1.0 1.0 1.0 water 81.5 80.0 77.0

[0173]The pH of the formulations was measured with a pH meter and the viscosity was measured with a Brookfield ...

Embodiment 3

[0179] Example 3: Effect of Chelating Agents

[0180] To understand the effect of chelating agents, take black tea, latte coffee and ketchup stains. The pH of the formulation was maintained with 1% citric acid.

[0181] The present invention A Comparative Example 07 Tergitol (15-S-7) 7.5 7.5 Sodium Lauryl Ether Sulfate 2 2 Hexyl Carbitol 5.0 5.0 Solvent - ethyl octanoate 2.5 2.5 citric acid 0.12 1.0 Sodium citrate 0.38 -- Dequest 2010 1.0 -- water 81.5 81.0

[0182] The pH of comparative formulation 07 was maintained at 3.0 by adding 1% citric acid. Cleanliness evaluations were performed on black tea, coffee with milk and ketchup.

[0183]

[0184] The difference in 2 SRI units is significant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| foaming density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com