Nanowire-fluorocarbon composite coating and preparation method thereof

A technology of composite coating and fluorocarbon coating, which is applied in the direction of coating, nanotechnology, nanotechnology, etc., can solve the problems of inability to arrange heat transfer channels, decrease of binding force, unfavorable droplet condensation, etc., to improve effective heat conduction Coefficient, prevent the accumulation of dust and dirt, solve the effect of poor thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

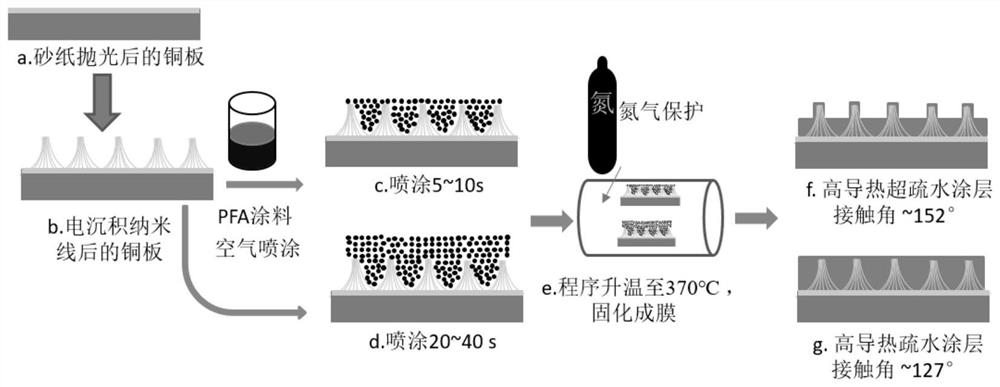

[0058] The technical scheme of the present invention is: firstly use the electrochemical deposition method to grow copper nanowires of a certain height on the surface of the metal substrate, then adjust the viscosity of the coating, and use an appropriate spraying process to form a film in the gaps of the nanowires. It solves the problem of poor heat transfer performance while condensing. The specific process is as follows:

[0059] 1. Substrate pretreatment: Use 800# and 3000# sandpaper to polish the copper substrate (copper substrate) sequentially, and polish the surface of the copper substrate. The polished substrate (copper substrate) was ultrasonically cleaned with acetone and ethanol, respectively, and then rinsed with deionized water.

[0060] 2. Electroplating nanowires: Place the copper substrate, porous alumina (PAA) template, filter paper, and copper sheet connected to the counter electrode in order and fix them with clips, and immerse the edge of the filter paper ...

Embodiment 2

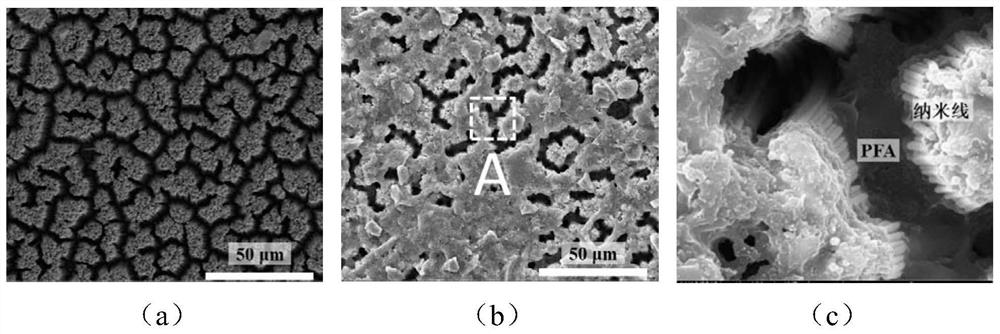

[0067]Construct the surface of 1# nanowire, and spray PFA to prepare 3# nanowire-PFA composite coating. The preparation steps are as follows: polish the copper substrate with 800# and 3000# sandpaper in sequence, and polish the substrate surface well. The polished substrates were ultrasonically cleaned with acetone and ethanol, respectively, and then rinsed with deionized water. Place the porous alumina (PAA) template (model 450-200), the filter paper and the counter electrode of the copper sheet in order and fix them with clips, and dip the edge of the filter paper into the electroplating solution to ensure that the solution can be completely absorbed by the filter paper through capillary action , and evenly distributed in the PAA template. A constant potential was applied between the copper substrate and the counter electrode to plate the nanowires. After electroplating for 1100 s, a layer of short copper nanowire arrays was attached to the copper substrate. After that, re...

Embodiment 3

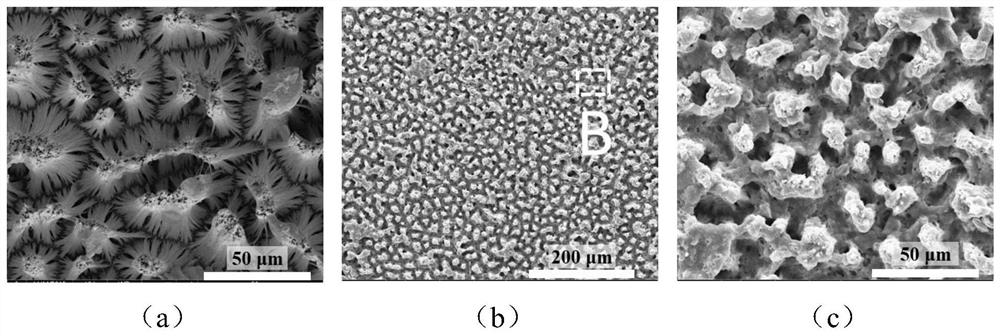

[0069] Construct 2# nanowire surface, and spray PFA to prepare nanowire-PFA composite surface, this embodiment differs from embodiment 1 in that the type of template used is changed, i.e. the distance between nanowires, the preparation steps are as follows: use 800# and 3000# sandpaper grinds the copper substrate in turn to polish the surface of the substrate well. The polished substrates were ultrasonically cleaned with acetone and ethanol, respectively, and then rinsed with deionized water. Place the porous alumina (PAA) template (model 450-110), the filter paper and the counter electrode of the copper sheet in sequence and fix them with clips, and dip the edge of the filter paper into the electroplating solution to ensure that the solution can be completely absorbed by the filter paper through capillary action , and evenly distributed in the PAA template. A constant potential was applied between the copper substrate and the counter electrode to plate the nanowires. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com