Device for graphene modified sintered neodymium iron boron permanent magnet materials

A graphene-modified and permanent-magnet material technology, which is applied to a device for graphene-modified sintered NdFeB permanent magnet materials, and in the field of graphene-modified sintered NdFeB, can solve the problem that the overall temperature is not high and the reaction temperature is difficult to control. , time-consuming and labor-intensive problems, to achieve the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

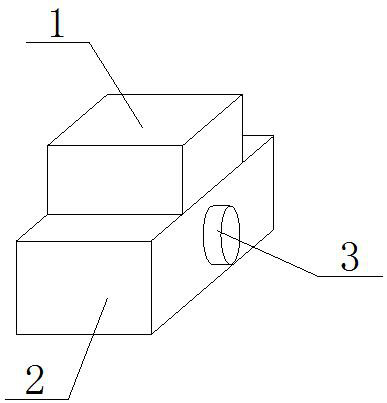

[0029] Such as figure 1 As shown, the present invention provides a kind of device of graphene modified sintered NdFeB permanent magnet material, comprises raw material distribution equipment 1, discharge plasma sintering equipment 2 and control panel 3, the bottom of raw material distribution equipment 1 is connected in discharge plasma Inside the sintering equipment 2 , a control panel 3 is fixedly installed on one side of the spark plasma sintering equipment 2 .

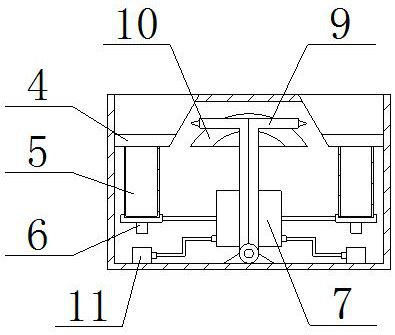

[0030] optional, such as figure 2As shown, the raw material distribution equipment 1 includes an induction valve 4, a material weighing bucket 5, an induction power head 6, an inductance connection channel 11 and a weighing control room 7. The raw material distribution equipment 1 is provided with a feed box inside, and the feed box The bottom of the material weighing bucket 5 is fixedly installed with a sensing valve 4, the top of the material weighing bucket 5 is lapped on the bottom of the feed box, and one en...

Embodiment 2

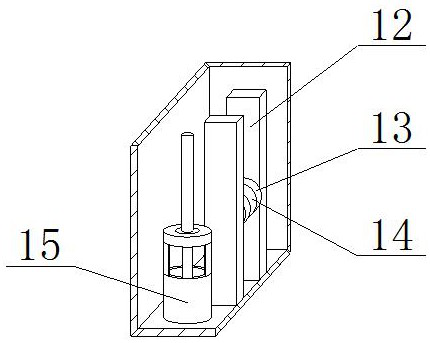

[0035] Such as Figure 4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: spark plasma sintering equipment 2 includes a heat storage and discharge chamber 17, a heat accumulation layer 18 and a temperature sensing probe 19, and one end of the heat storage and discharge chamber 17 is fixedly connected Inside the heat gathering layer 18 , the bottom of the temperature sensing probe 19 is fixedly installed inside the heat gathering layer 18 .

[0036] preferred, such as Figure 5 As shown, the spark plasma sintering equipment 2 is provided with a material sintering mold 21 inside, the two ends of the material sintering mold 21 are fixedly installed with an electrode layer 23, the bottom of the electrode layer 23 is provided with a pulse current transmitter 24, and the two sides of the electrode layer 23 are fixed. An electron reflective layer 25 is installed, and a material receiving port 22 is opened on the top of the material sinteri...

Embodiment 3

[0040] Such as Image 6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: preferably, an internal gas control device 20 is fixedly installed inside the spark plasma sintering device 2, and the internal gas control device 20 is located in the discharge plasma sintering device. On both sides of the sintering equipment 2, the internal gas control equipment 20 includes a gas exchange plate 26, an argon / vacuum extraction and infusion chamber 27, an automatic telescopic connecting rod 28, an air pressurized extraction and injection chamber 29, and a limit card joint 30. The bottom of the vacuum extraction and infusion chamber 27 is fixedly connected to the top of the gas exchange plate 26, one end of the automatic telescopic connecting rod 28 is fixedly connected to the top of the argon / vacuum extraction and infusion chamber 27, and the other end of the automatic telescopic connecting rod 28 is fixedly connected to the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com