Co-extrusion type solar module back plate and preparation method thereof

A solar module and backplane technology, applied in chemical instruments and methods, electrical components, semiconductor devices, etc., can solve the problems of limited absorption conversion rate of photovoltaic panels, achieve good light transmission, excellent impact resistance, and improve conversion efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

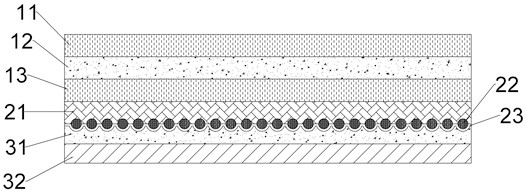

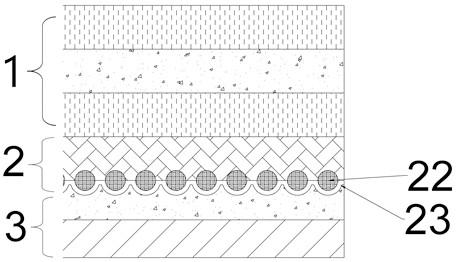

[0031] refer to Figure 1-2 , a co-extruded solar module backsheet, its whole from bottom to top is EVA coating 11, first support layer 12, EVA partition layer 13, filling adhesive layer 21, metal plating layer 23, second support layer 31 , weather-resistant layer 32, a number of glass beads 22 are fixed between the filling adhesive layer 21 and the metal coating 23;

[0032] EVA coating 11, first support layer 12, EVA partition layer 13 three-layer co-extrusion combined to form upper backplane layer 1; filling adhesive layer 21, glass beads 22, metal coating 23 bonded to form reflective layer 2; The support layer 31 and the weather-resistant layer 32 are co-extruded and combined to form the lower backplane layer 3;

[0033] The glass beads 22 are arranged adjacent to each other, evenly distributed, and embedded in the filling adhesive layer 21 and the metal plating layer 23; the metal plating layer 23 is distributed along the contact surface with the filling adhesive layer 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com