A toughened intermediate and preparation method thereof, and a toughened mosquito repellent polymer biodegradable composite material for 3D printing

A polymer material and 3D printing technology, applied in additive processing, carboxylate preparation, chemical instruments and methods, etc., can solve problems such as the decline of mosquito repellent effect, expand application development space, enhance network structure, and reduce pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

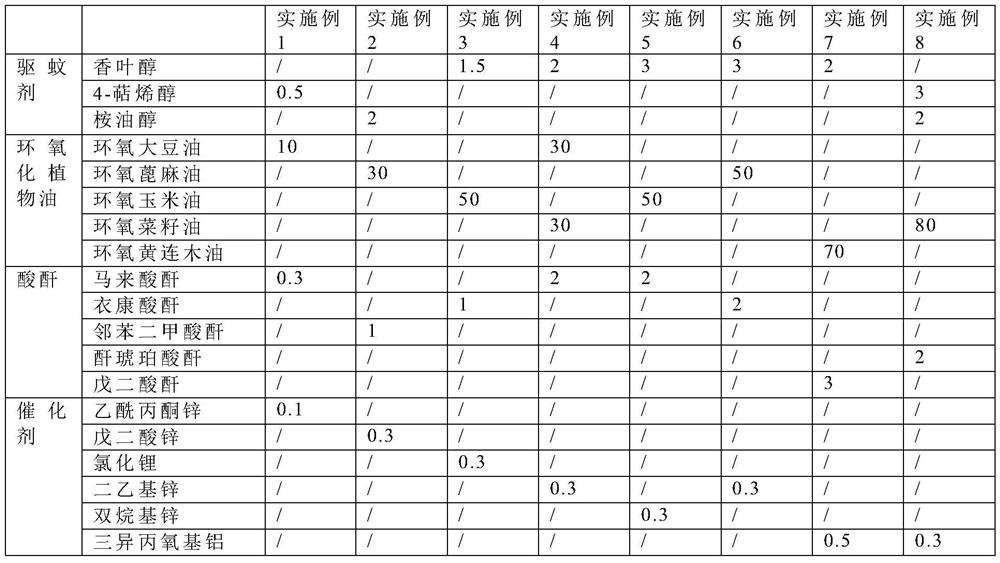

Embodiment 1

[0038] Epoxidized vegetable oil, mosquito repellent, acid anhydride, and catalyst were weighed according to the toughening intermediate raw materials and their parts by weight described in Example 1 in Table 1, and were pre-dried in an oven.

[0039] Then, the mosquito repellent and the acid anhydride are slowly stirred evenly, and gradually heated to 90° C. within one hour to obtain a mosquito repellent intermediate.

[0040] Then, epoxidized vegetable oil and catalyst are added, and the temperature is raised to 150° C. and kept under catalyst conditions for 1 hour to obtain a toughened intermediate.

Embodiment 2

[0042] The raw materials were weighed according to the toughening intermediate raw materials and their parts by weight described in Example 2 in Table 1.

[0043] Then, the mosquito repellent and the acid anhydride are slowly stirred evenly, and then gradually heated to 95° C. within one hour to obtain a mosquito repellent intermediate.

[0044] Then, epoxidized vegetable oil and catalyst are added, and the temperature is raised to 155° C. and kept under catalyst conditions for 1 hour to obtain a toughened intermediate.

Embodiment 3

[0046] The raw materials were weighed according to the toughening intermediate raw materials and their parts by weight described in Example 3 in Table 1.

[0047] Then, the mosquito repellent and the acid anhydride are slowly stirred evenly, and gradually heated to 100° C. within one hour to obtain a mosquito repellent intermediate.

[0048] Then, the epoxidized vegetable oil and the catalyst are added, and the temperature is raised to 160° C. and kept under the catalyst condition for 2 hours to obtain a toughened intermediate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com