Anti-blocking filter element for filtering oil products

An anti-blocking and oil product technology, which is applied in the direction of filtration separation, magnetic separation, solid separation, etc., can solve the problems of poor corrosion resistance, filter elements can not effectively remove various impurities and metal dust, etc., and achieve improved filtration efficiency and good oil resistance , High oil-water separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

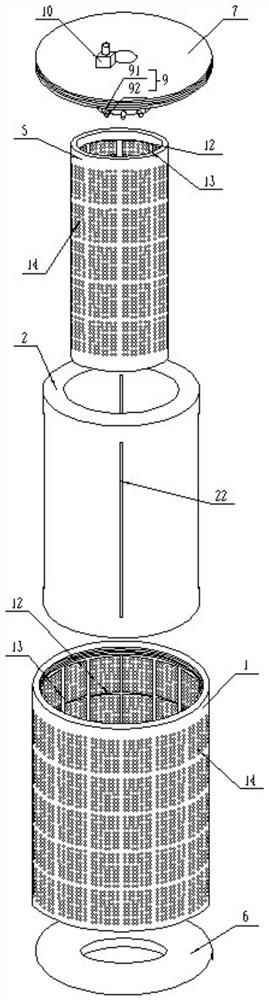

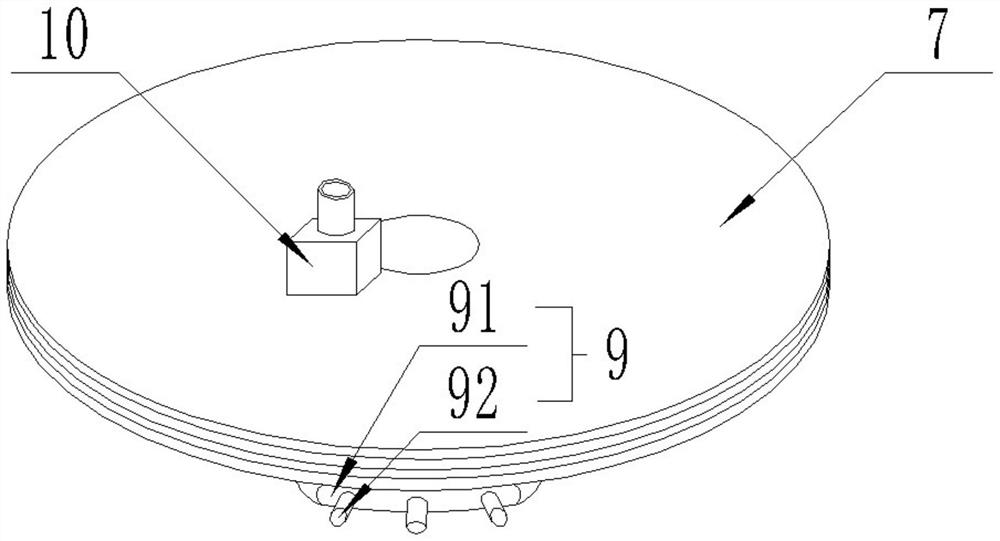

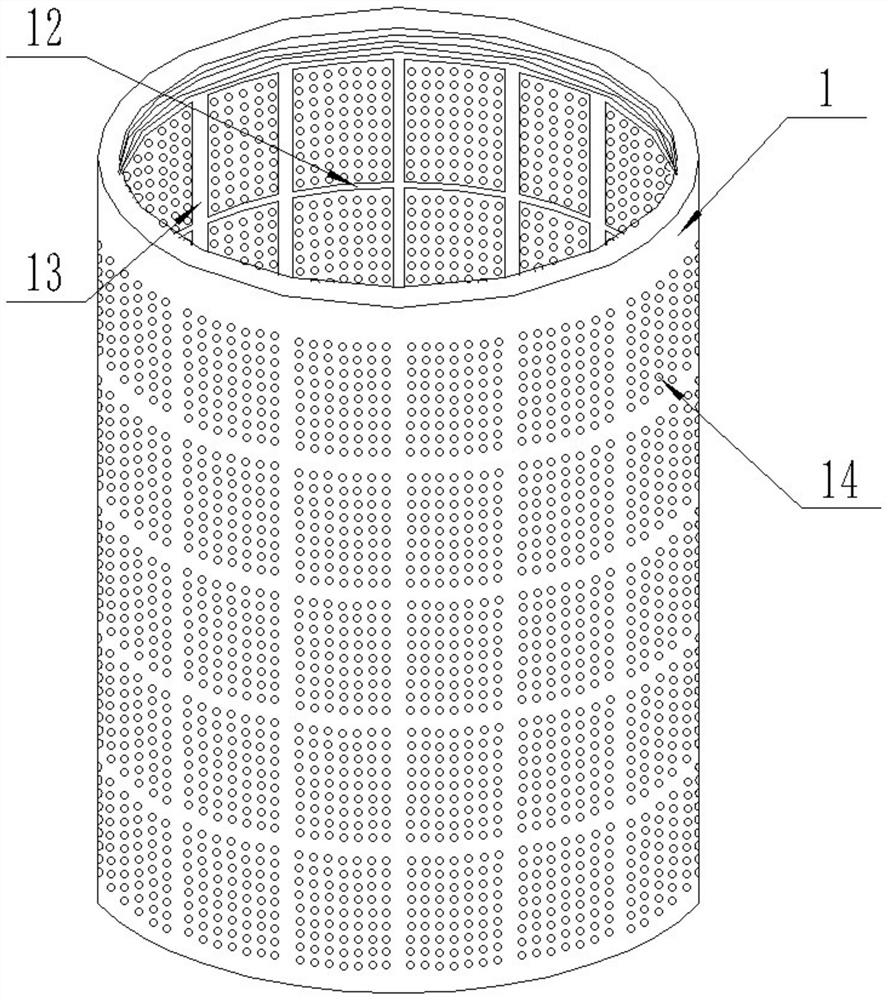

[0020] An anti-clogging filter element for oil filtration, an outer filter cartridge 1, a cartridge bottom 6 and a cartridge cover 7, the outer filter cartridge 1 is coaxially provided with an inner filter cartridge 5, the inner filter cartridge 5 and the outer filter cartridge A magnetic filter cartridge 2 is sandwiched between the cartridges 1, a water pressure sensor and a slag removal device 9 are installed on the inner surface of the cartridge cover 7, and a plurality of Transverse grooves 12 and longitudinal grooves 13, the transverse grooves 12 and the longitudinal grooves 13 are arranged in a cross, and a filtering area is formed between the transverse grooves 12 and the longitudinal grooves 13, and the filtering area is set There are several filter holes 14, the average pore diameter of the filter holes of the magnetic filter cartridge 2 is 50 μm, the average pore diameter of the filter holes of the outer filter cartridge 1 and the inner filter cartridge 5 is 20 μm, an...

Embodiment 2

[0024] An anti-clogging filter element for oil filtration, an outer filter cartridge 1, a cartridge bottom 6 and a cartridge cover 7, the outer filter cartridge 1 is coaxially provided with an inner filter cartridge 5, the inner filter cartridge 5 and the outer filter cartridge A magnetic filter cartridge 2 is sandwiched between the cartridges 1, a water pressure sensor and a slag removal device 9 are installed on the inner surface of the cartridge cover 7, and a plurality of Transverse grooves 12 and longitudinal grooves 13, the transverse grooves 12 and the longitudinal grooves 13 are arranged in a cross, and a filtering area is formed between the transverse grooves 12 and the longitudinal grooves 13, and the filtering area is set There are several filter holes 14, the average pore diameter of the filter holes of the magnetic filter cartridge 2 is 50 μm, the average pore diameter of the filter holes of the outer filter cartridge 1 and the inner filter cartridge 5 is 20 μm, an...

Embodiment 3

[0028] An anti-clogging filter element for oil filtration, an outer filter cartridge 1, a cartridge bottom 6 and a cartridge cover 7, the outer filter cartridge 1 is coaxially provided with an inner filter cartridge 5, the inner filter cartridge 5 and the outer filter cartridge A magnetic filter cartridge 2 is sandwiched between the cartridges 1, a water pressure sensor and a slag removal device 9 are installed on the inner surface of the cartridge cover 7, and a plurality of Transverse grooves 12 and longitudinal grooves 13, the transverse grooves 12 and the longitudinal grooves 13 are arranged in a cross, and a filtering area is formed between the transverse grooves 12 and the longitudinal grooves 13, and the filtering area is set There are several filter holes 14, the average pore diameter of the filter holes of the magnetic filter cartridge 2 is 50 μm, the average pore diameter of the filter holes of the outer filter cartridge 1 and the inner filter cartridge 5 is 20 μm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| oil-water separation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com