Method and equipment for precise micro-welding of nonferrous metals through composite dual wavelengths

A non-ferrous metal, welding method technology, applied in welding equipment, laser welding equipment, metal processing equipment and other directions, can solve the problems of small welding spot welding, the size of the spot cannot be adjusted, and the welding spot is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following specific implementation methods are used to explain the technical solutions of the claims of the present invention, so that those skilled in the art can understand the claims. The protection scope of the present invention is not limited to the following specific implementation structures. The protection scope of the present invention includes the technical solution of the claims of the present invention made by those skilled in the art and is different from the following specific embodiments.

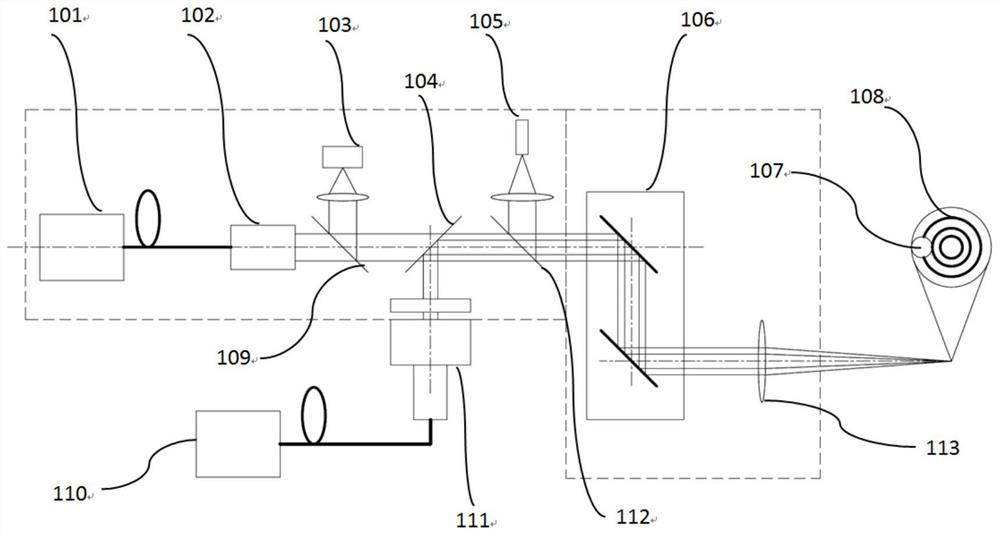

[0033] Such as figure 1 As shown, in the embodiment, the first laser 101 is a blue laser: the wavelength is 440-460nM, the power is adjustable from 10-250W, the working mode is continuous, the output fiber core diameter is 200-400uM, and the numerical aperture is 0.10-0.23. A first collimator 102 is arranged on the output optical path of the first laser 101 to adjust the divergent laser light output by the optical fiber to be close to parallel light. A total refle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com