A wire pole production line

A production line and utility pole technology, which is applied in the field of utility pole production equipment, can solve problems such as unreasonable layout of utility pole production lines, large manpower and material resources for pouring molds, and large floor space, so as to save labor costs and time costs, and save occupational costs. Floor space, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

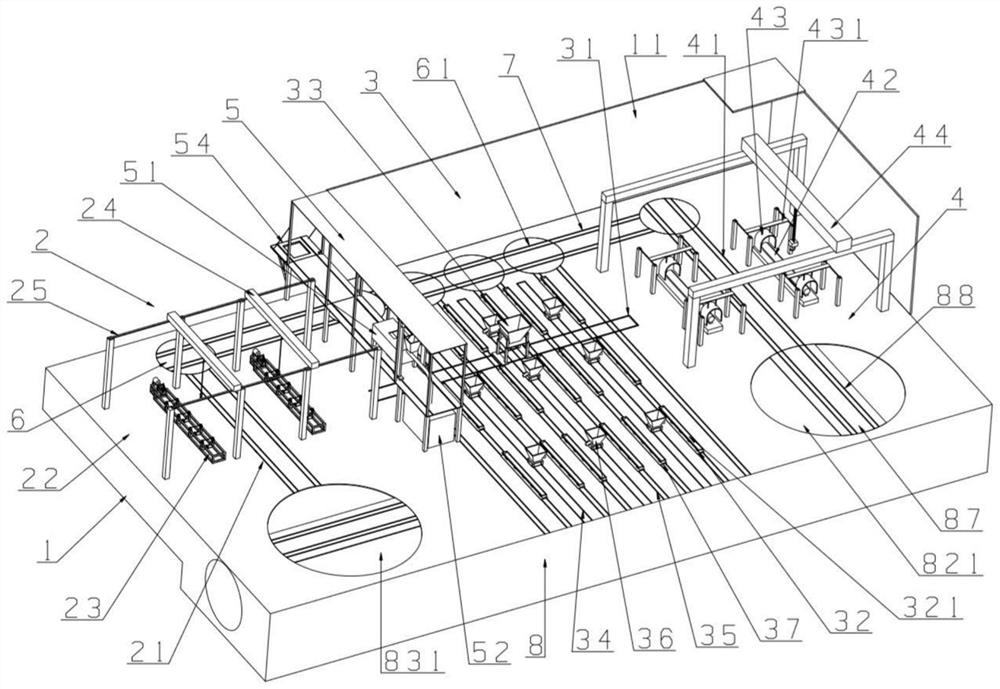

[0039] The top of the foundation 1 is divided into a cage line 2, a watering line 3 and a centrifugal line 4 in turn, and a workshop 11 is provided on the foundation 1.

[0045] The first track 21, the fifth track 41, the sixth track 7, the seventh track 61 and the eighth track 88 have a total of two, and are mutually

[0046] In addition, another real-time manner of this embodiment is that the suspension frame 54 is installed on the support frame in a telescopic manner

[0053] The foregoing descriptions of specific exemplary embodiments of the present invention have been presented for purposes of illustration and description. these descriptions

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com