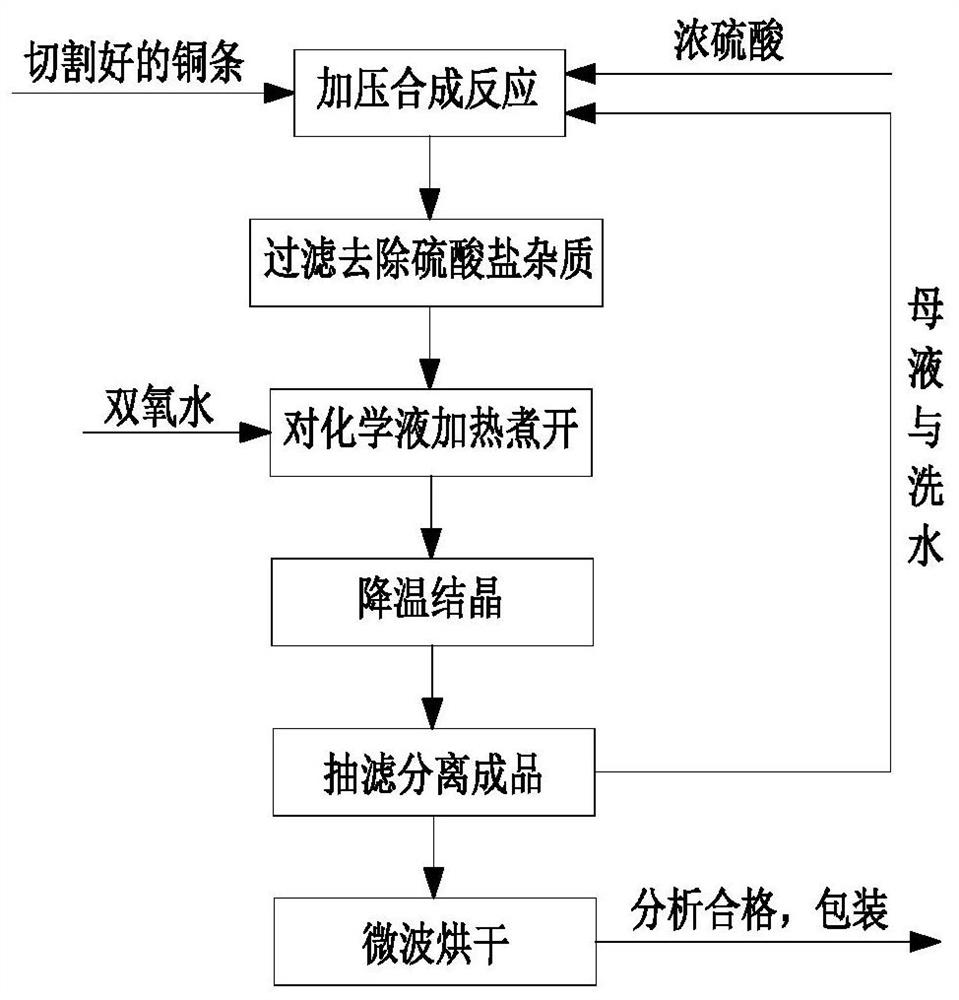

Production process for producing high-purity copper sulfate by pressurization method

A production process, copper sulfate technology, applied in the direction of copper sulfate, etc., can solve the problems of high cost, poor product quality, large quantity, etc., and achieve the effects of improving reaction speed, improving production efficiency, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Weigh 40 kg of copper bars and place them in a 25L reactor to 2 / 3 of the volume, and add 20L of copper sulfate mother liquor with a copper ion content of 60±5g / L and a sulfuric acid content of 14-18%. When it reaches 80 degrees, stop heating. Analyze copper ions and acidity content. Pressurized reaction, after 4 hours of pressurized reaction, detect the rising speed of copper ions in time intervals, when the copper ions rise to 140g / L, the material is discharged, filtered to remove impurities, cooled to crystallize, separated and dried. Get the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com