Flame-retardant PE breathable film composite material and preparation method thereof

A technology for composite materials and breathable membranes, which is applied in the field of flame-retardant PE breathable membrane composite materials and its preparation, and can solve problems such as the difficulty of flame-retardant modification, the difficulty of flame-retardant modification of PE materials, and the reduction of flame-retardant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

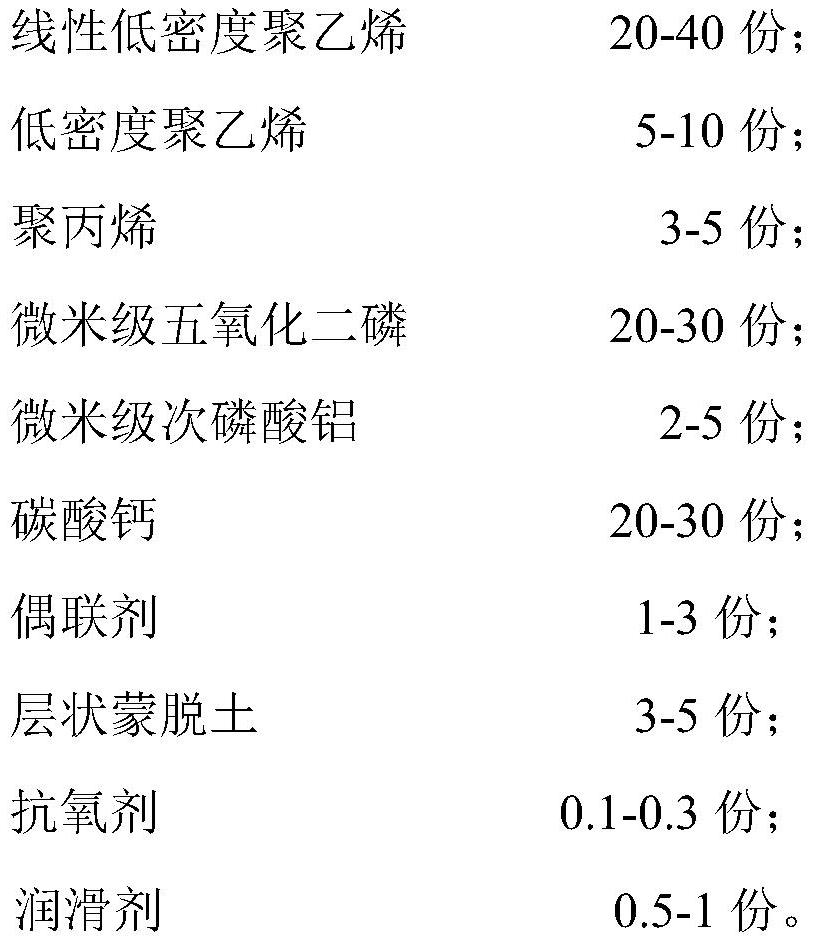

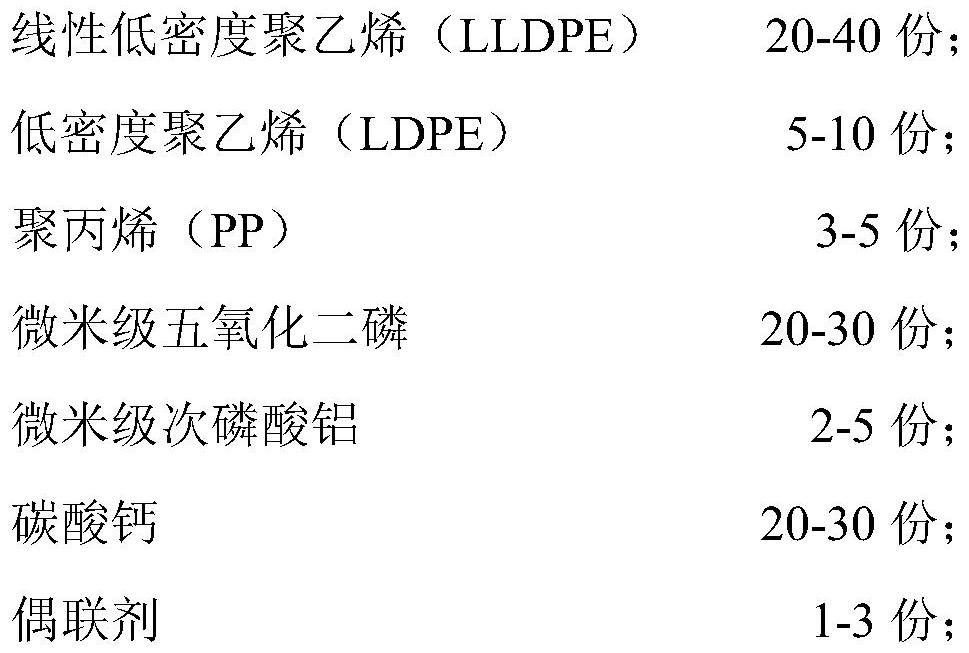

Method used

Image

Examples

Embodiment 1

[0034] LLDPE: 40 parts;

[0035] LDPE: 5 parts

[0036] PP: 5 parts

[0037] Micron grade phosphorus pentoxide: 20 parts

[0038] Micron aluminum hypophosphite: 5 parts

[0039] Calcium carbonate: 20 parts

[0040] Titanate coupling agent AC-211 (Nanjing Aocheng): 3 parts

[0041] Sodium-based layered montmorillonite G105 (NANOCO, USA): 2 parts

[0042] Antioxidant MD-697 (Lianlong): 0.3 parts

[0043] Hyperbranched polyether C100T (Wuhan hyperbranched resin): 0.6 parts

[0044] Polysiloxane SF1550 (Momentive): 0.3 parts

Embodiment 2

[0046] LLDPE: 30 parts

[0047] LDPE: 8 parts

[0048] PP: 3 parts

[0049] Micron grade phosphorus pentoxide: 20 parts

[0050] Micron-sized aluminum hypophosphite: 2 parts

[0051] Calcium carbonate: 30 parts

[0052] Titanate coupling agent AC-211 (Nanjing Aocheng): 2 parts

[0053] Sodium-based layered montmorillonite G105 (NANOCO, USA): 5 parts

[0054] Antioxidant MD-697 (Lianlong): 0.1 parts

[0055] Hyperbranched polyether C100T (Wuhan hyperbranched resin): 0.3 parts

[0056] Polysiloxane SF1550 (Momentive): 0.15 parts

Embodiment 3

[0058] LLDPE: 32 parts

[0059] LDPE: 10 parts

[0060] PP: 4 parts

[0061] Micron-sized phosphorus pentoxide: 22 parts

[0062] Micron-sized aluminum hypophosphite: 3 parts

[0063] Calcium carbonate: 22 parts

[0064] Titanate coupling agent AC-211 (Nanjing Aocheng): 1 part

[0065] Sodium-based layered montmorillonite G105 (NANOCO, USA): 4 parts

[0066] Antioxidant MD-697 (Lianlong): 0.25 parts

[0067] Hyperbranched polyether C100T (Wuhan hyperbranched resin): 0.2 parts

[0068] Polysiloxane SF1550 (Momentive): 0.1 parts

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com