Flame-treatment-free polypropylene composition for automobile bumper and preparation method of flame-treatment-free polypropylene composition

A polypropylene composition and the technology of the composition are applied in the field of polypropylene composition for automobile bumpers and its preparation, which can solve the problems that the addition of a large amount of polar modifier on the surface of oligomers affects the mechanical properties, etc., and achieve the improvement of paint Molecular weight, excellent surface polarity, and the effect of overcoming precipitation defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

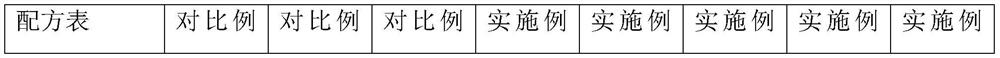

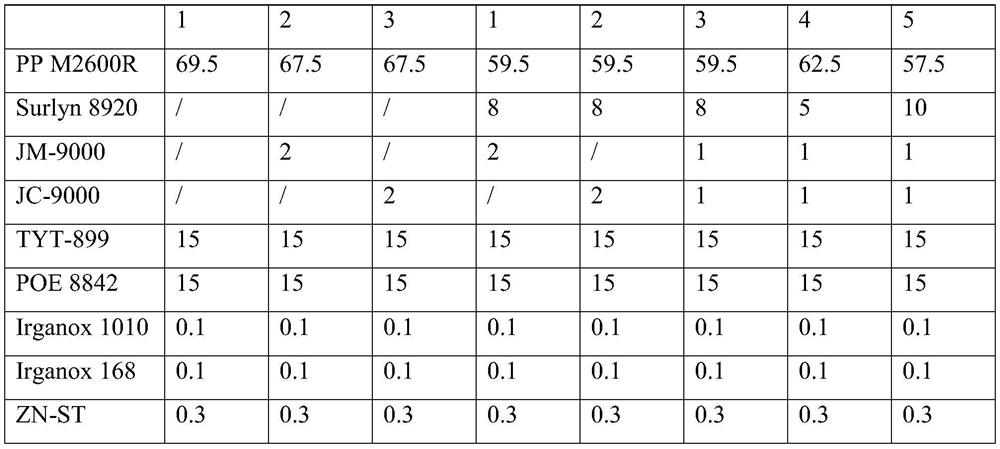

[0028] According to the weight ratio shown in Table 1, 59.5 parts by weight of polypropylene PP M2600R, 8 parts by weight of ionic polymer Surlyn 8920, 2 parts by weight of polyetheramine JM-9000, 15 parts by weight of talcum powder TYT-899, and 15 parts by weight of elastomer POE8842, 0.1 weight part of hindered phenolic primary antioxidant Irganox 1010, 0.1 weight part of phosphite secondary antioxidant Irganox 168, 0.3 weight part of processing aid zinc stearate ZN-ST were mixed evenly, and passed through 56:1 long Diameter ratio twin-screw extrusion granulation, the extrusion temperature is 200 ℃.

Embodiment 2

[0030] According to the weight ratio shown in Table 1, 59.5 parts by weight of polypropylene PP M2600R, 8 parts by weight of ionic polymer Surlyn 8920, 2 parts by weight of polyether polyol JC-9000, 15 parts by weight of talcum powder TYT-899, 15 parts by weight of elastic Body POE8842, 0.1 weight part of hindered phenolic primary antioxidant Irganox 1010, 0.1 weight part of phosphite secondary antioxidant Irganox 168, 0.3 weight part of processing aid zinc stearate ZN-ST are mixed uniformly, passed 56:1 Aspect ratio twin-screw extrusion granulation, the extrusion temperature is 200 ℃.

Embodiment 3

[0032] According to the weight ratio shown in Table 1, 59.5 parts by weight of polypropylene PP M2600R, 8 parts by weight of ionic polymer Surlyn 8920, 1 part by weight of polyetheramine JM-9000, 1 part by weight of polyether polyol JC-9000, 15 parts by weight Talc powder TYT-899, 15 parts by weight of elastomer POE 8842, 0.1 part by weight of hindered phenolic primary antioxidant Irganox 1010, 0.1 part by weight of secondary phosphite antioxidant Irganox 168, 0.3 part by weight of processing aid stearic acid Zinc ZN-ST is mixed evenly, and granulated by twin-screw extrusion with a length-to-diameter ratio of 56:1, and the extrusion temperature is 200°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com