A kind of glass polishing liquid and its application

A polishing liquid and glass technology, applied in glass production, polishing compositions containing abrasives, etc., can solve the problem that the performance of polishing liquid still needs to be optimized, so as to improve surface quality, reduce surface defects, improve dispersion and anti-settling sexual effect

Active Publication Date: 2022-07-08

安徽中飞科技有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the performance of the current polishing fluid still needs to be optimized

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0025] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below with reference to specific embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

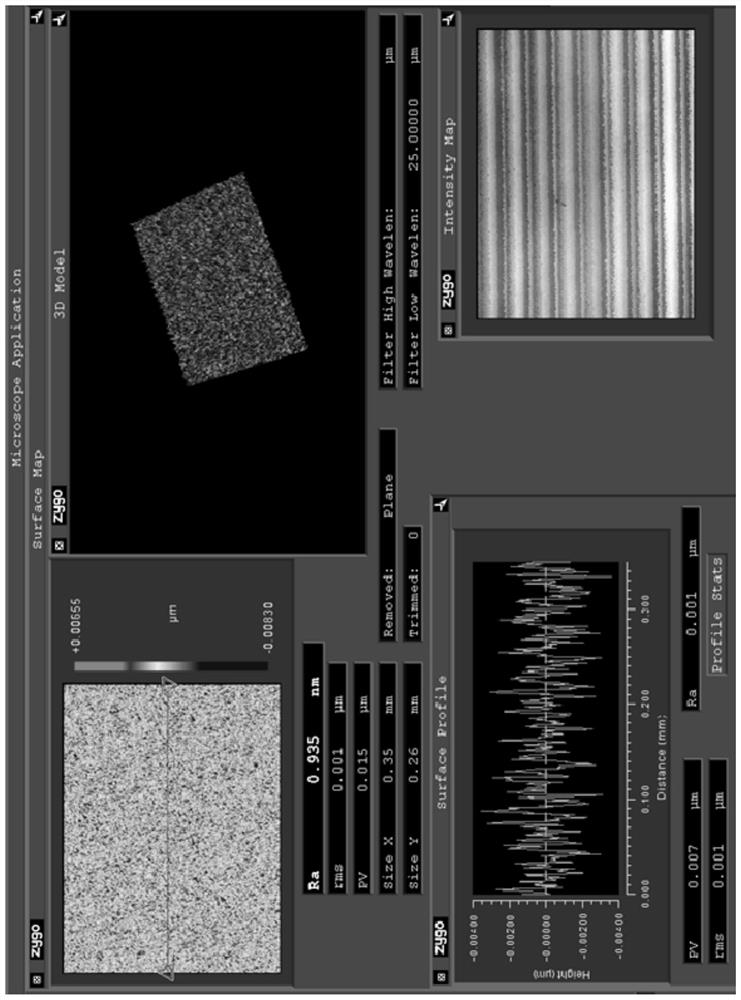

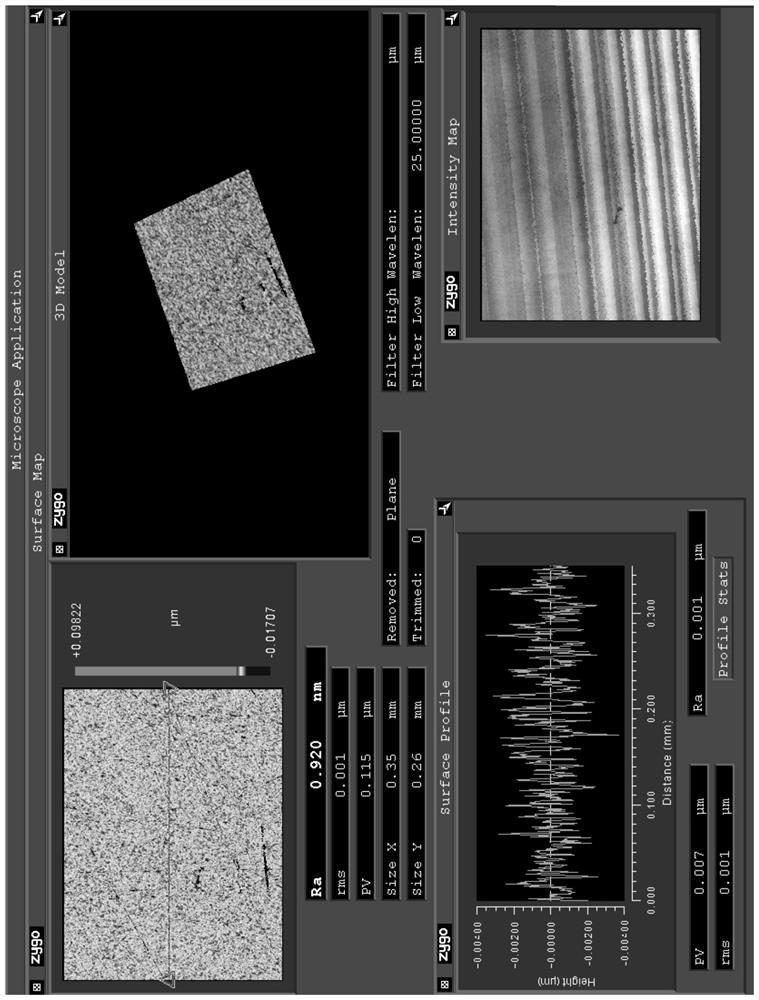

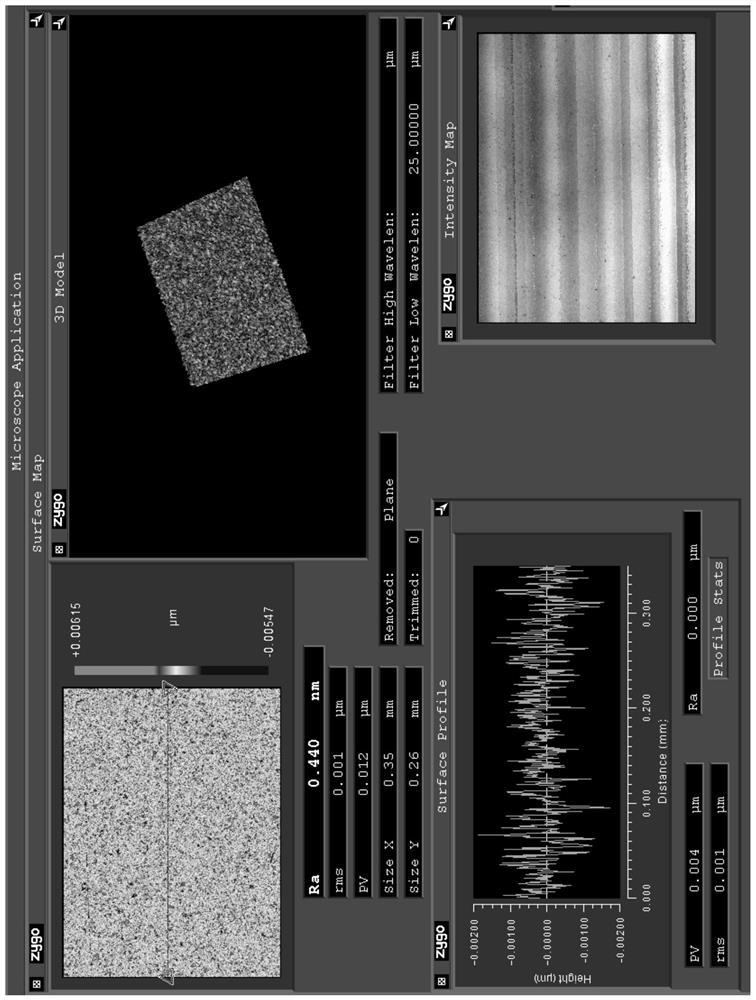

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a polishing liquid for glass, which belongs to the field of glass surface processing. The polishing liquid for glass of the present invention includes the following components: polishing powder 4-10g / L, dispersant 300-315g / L, oxidizing etchant 20-120g / L, alkaline etchant 3-15g / L, acid-base reagent 0.1 ‑1g / L, and the balance is water; wherein the acid-base reagent is at least one of an acid reagent and an alkaline reagent, and the dispersant is polydimethylsiloxane. The polishing liquid for glass of the present invention uses the synergistic effect of mechanical grinding and chemical corrosion to reduce the surface defects caused by the traditional polishing method and improve the surface quality of the glass. At the same time, polydimethylsiloxane is used as a dispersant to better improve the The dispersibility and anti-settling properties of the polishing powder give full play to the mechanical grinding effect of the polishing powder.

Description

technical field [0001] The invention belongs to the field of glass surface processing, and in particular relates to a polishing liquid for glass and its application. Background technique [0002] At present, the research direction and application of infrared technology has become an important direction of the development of modern optical technology, and it has promoted the development and progress of infrared material technology. Common infrared optical crystal materials such as germanium, silicon, zinc sulfide, zinc selenide, and chalcogenide glass are the main optical materials currently used, which are not only limited in type, but also expensive. Chalcogenide glass is a special glass material with excellent infrared transmission properties. In recent years, it has received extensive attention due to its outstanding performance in optics. [0003] Chalcogenide glass has the advantages of low thermal difference coefficient, wide transmission range, high transmittance, go...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09G1/02

CPCY02P40/57

Inventor 杨安潘慧

Owner 安徽中飞科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com