High-toughness bi-component epoxy structural adhesive and preparation method thereof

An epoxy structural adhesive, two-component technology, used in epoxy resin adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of poor impact resistance, epoxy structural adhesive constraints, Problems such as low fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

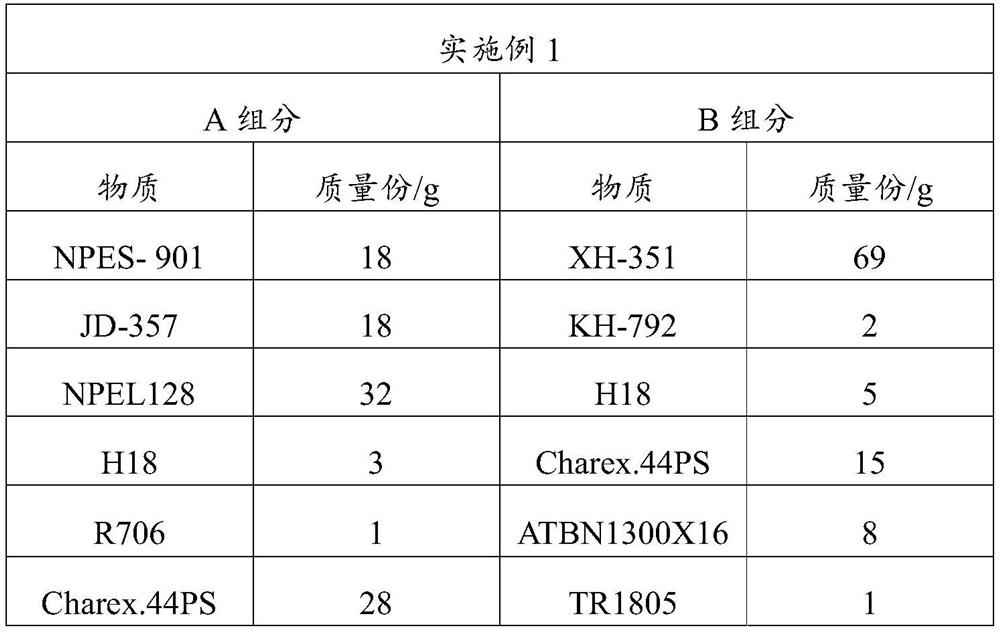

Embodiment 1

[0031] The components and component weights of the high-toughness two-component epoxy structural adhesive are shown in the following table:

[0032]

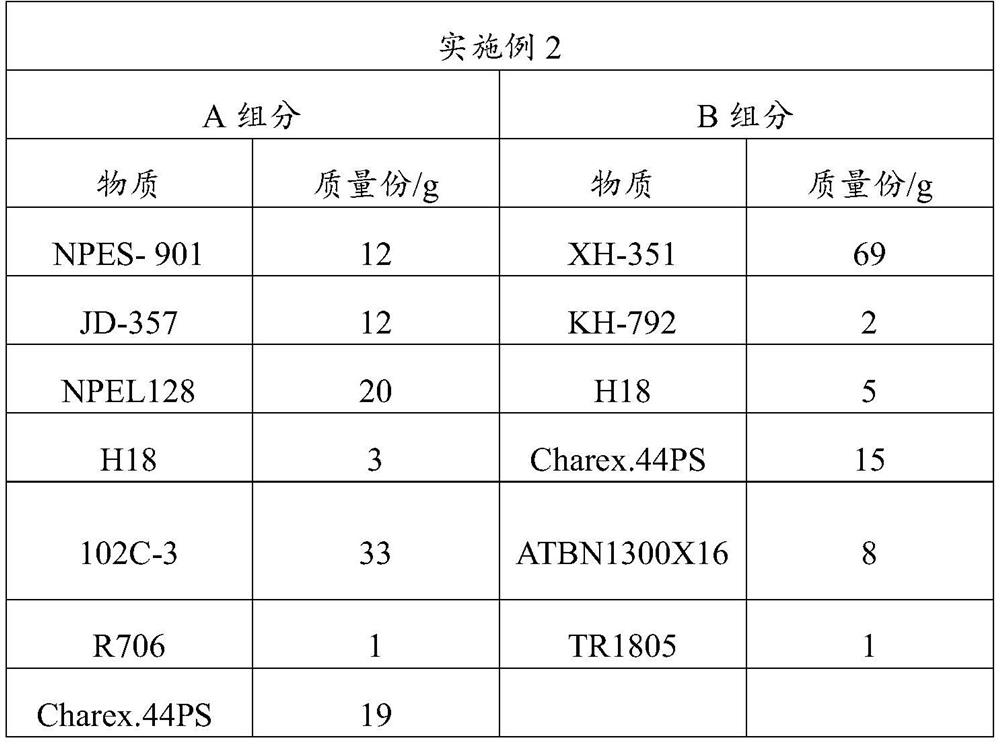

Embodiment 2

[0034] The components and component weights of the high-toughness two-component epoxy structural adhesive are shown in the following table:

[0035]

Embodiment 3

[0037] The components and component weights of the high-toughness two-component epoxy structural adhesive are shown in the following table:

[0038]

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Lap shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com