Ion exchange method for gas generation in uranium extraction process

A technology for ion exchange and extraction process, which is applied in the field of ion exchange where gas is generated in the uranium extraction process, and can solve the problems of increased dosage of transformation agent, more waste water, and reduced saturated working capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

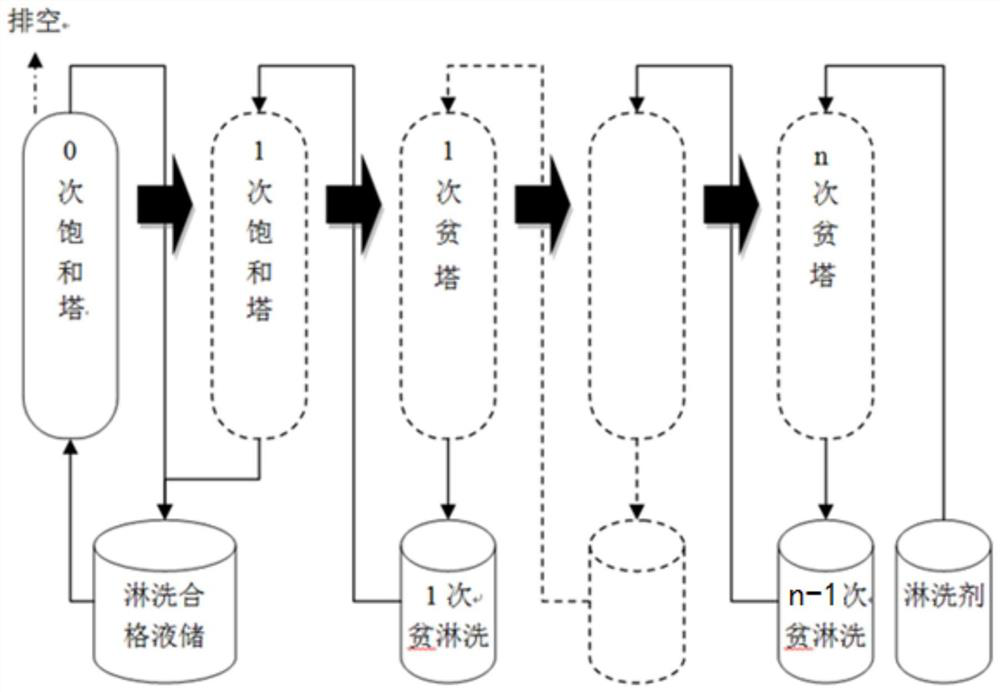

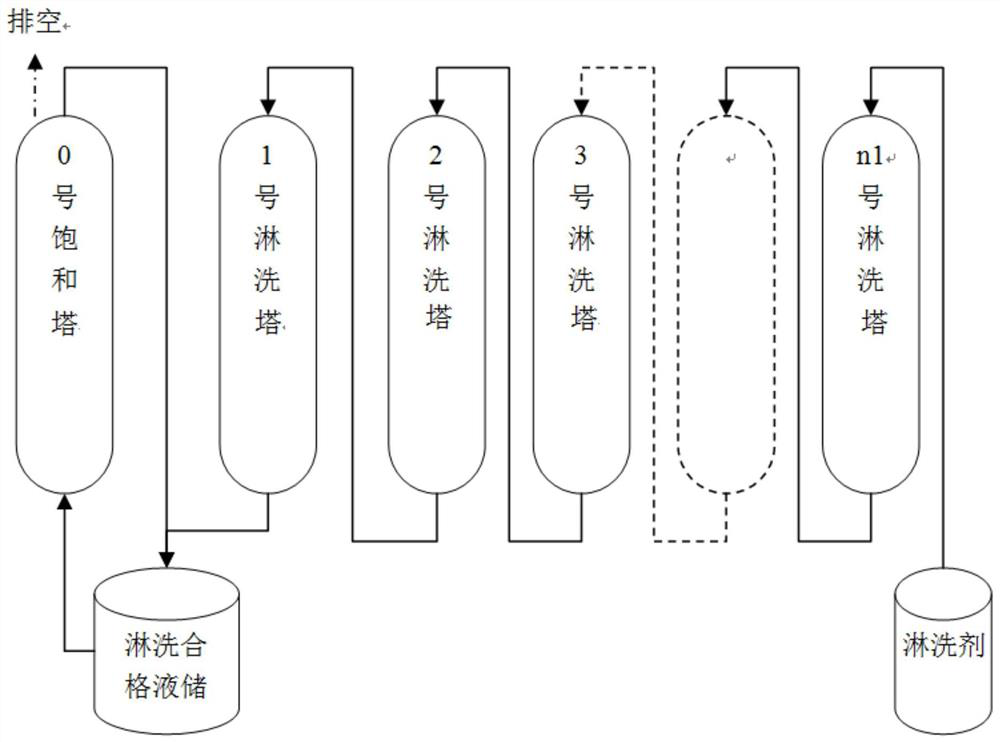

Method used

Image

Examples

Embodiment 1

[0064] Weakly basic anion resin is used to adsorb uranium in a certain carbonate system, and the carbonate is leached.

[0065] The solution was adjusted to pH 6.0 by adding sulfuric acid. Fixed-bed 5-column adsorption in series. The bed height is 60% of the effective height in the tower, and the contact time for a single tower is 10 minutes. The liquid is fed from the top, and the top of the tower is exhausted. The height of the liquid level is controlled at 85-95% of the tower height, and the exhaust control P1 / P0≥95%. The first tower adsorption tail liquid is dynamically adjusted to pH 6.0. The concentration of uranium in the adsorption tail liquid of the fourth tower reaches 1mg / L, and the first tower is cut out, and the bottom liquid of the fifth tower is circulated and exhausted. The looseness of the exhaust bed is 1.4. The tower is used, and then the tail is cut into the new tower after transformation and washing. The uranium concentration of the loaded resin is 70m...

Embodiment 2

[0068] Weakly basic anion resin is used to adsorb uranium in a sulfuric acid system, and carbonate leaching is used.

[0069] Fixed-bed 5-column adsorption in series. The bed height is 70% of the effective height in the tower, and the contact time for a single tower is 5 minutes. The liquid is fed from the top, and the top of the tower is exhausted. The height of the liquid level is controlled at 90-95% of the tower height, and the exhaust control P1 / P0≥90%. The first tower adsorption tail liquid is dynamically adjusted to pH ≤ 2.0. The concentration of uranium in the adsorption tail liquid of the 4th tower reaches 1mg / L, the first tower is cut out, and the bottom of the 5th tower is circulated and exhausted. The looseness of the exhaust bed is 1.2. The tower is used, and then the tail is cut into the new tower after transformation and washing. The uranium concentration of the loaded resin is 100mg / ml.

[0070] Use the eluting qualified liquid to carry out circular elutria...

Embodiment 3

[0074] Use weakly acidic cationic resin to adsorb uranium in a certain carbonate system, and rinse with hydrochloric acid.

[0075] The solution was adjusted to pH 6.0 by adding sulfuric acid. Fixed-bed 6-column adsorption in series. The bed height is 50% of the effective height in the tower, and the contact time for a single tower is 10 minutes. The liquid is fed from the top, and the top of the tower is exhausted. The height of the liquid level is controlled at 85-95% of the tower height, and the exhaust control P1 / P0≥85%. The first tower adsorption tail liquid is dynamically adjusted to pH 6.0. The concentration of uranium in the adsorption tail liquid of the fifth tower reaches 1mg / L, and the first tower is cut out, and the lower inlet liquid of the sixth tower is circulated and exhausted. The looseness of the exhaust bed is 1.8. The tower is used, and then the tail is cut into the new tower after transformation and washing. The uranium concentration of the loaded resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com