A kind of electrode electroplating nickel plating process

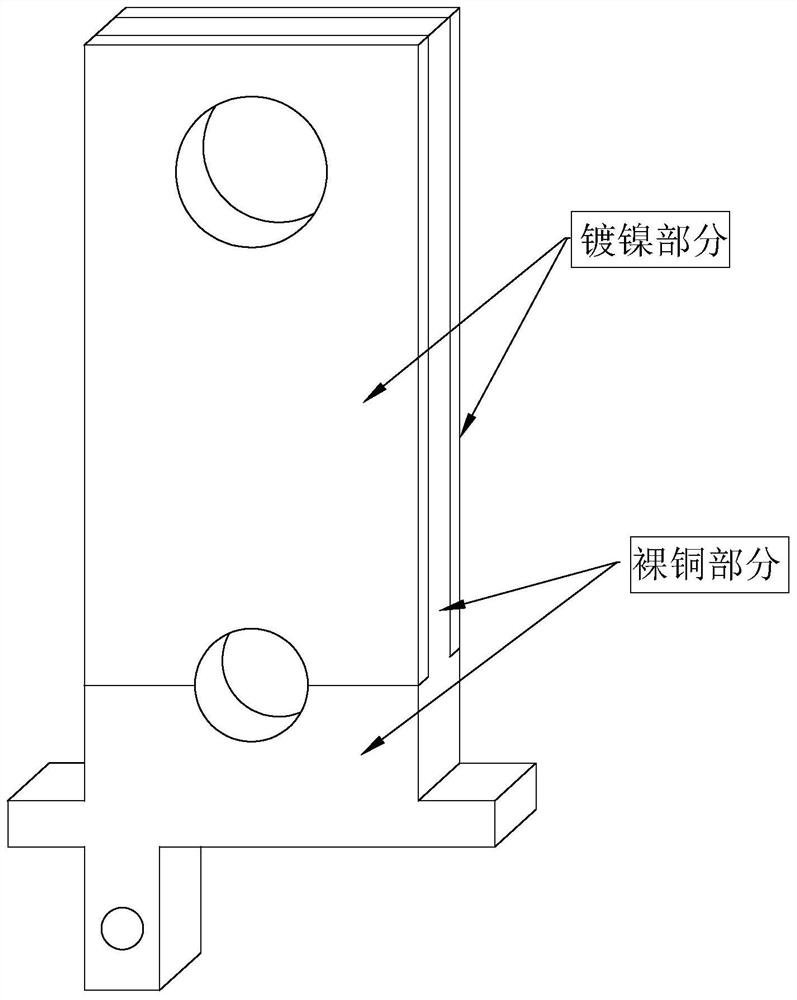

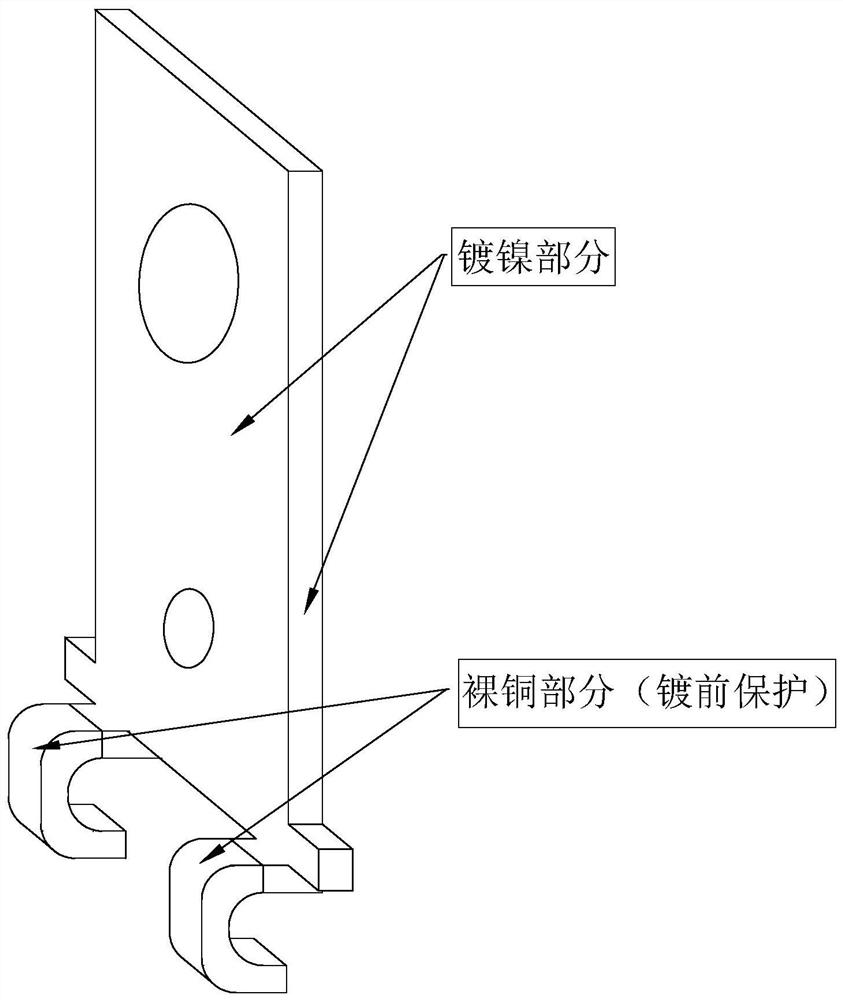

An electrode and nickel-plating technology, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve the problems of affecting the service life and safety of IGBT, fatal danger of automobile safety, and exposed side of electrodes, etc. The effect of electroplating surface quality, convenient plating adhesion, and improving roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below:

[0031] The electroplating nickel plating process of a kind of electrode in the present embodiment comprises the following specific steps:

[0032] (1) Carry out the following pretreatment to the electrode;

[0033] Degreasing and derusting: Put the polished electrode into the drum, which contains 1 / 2 volume of degreasing and derusting solution, which contains: Accelerator 2.5-3.5g / L, diffusing agent 1.5-2.5g / L, penetrating agent 2-3g / L and 20wt%-50wt% nitric acid. The reasonable proportion of accelerator, diffusing agent and penetrating agent can speed up the dissolution of oil stains on the electrode surface. Nitric acid can effectively remove rust stains and oxides on the electrode surface. Clean under rotation for 30-60 minutes to achieve the purpose of degreasing and rust removal, and improve the smoothness of the electrode surface;

[0034] Ultrasonic cleaning: The electrode after degreasing and rust remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com