High-speed railway brake pad friction block adopting composite material transition layer and preparation method thereof

A composite material and transition layer technology, applied in the direction of friction lining, mechanical equipment, etc., can solve the problems of the friction material and the steel back detachment, the decrease of the bonding force between the friction material and the steel back, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

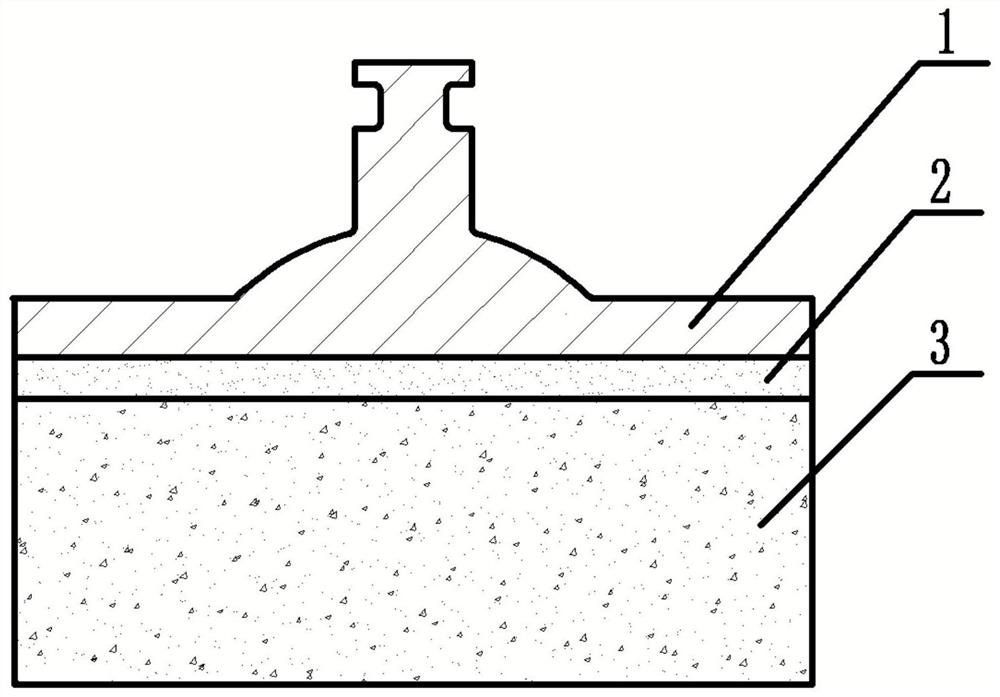

[0048] A method for preparing a high-speed rail brake pad friction block using a composite material transition layer, comprising the following steps:

[0049] a. Using weighing equipment, weigh the raw materials of each material according to the weight ratio of the materials in the transition layer 2 of the composite material, put the raw materials into the three-dimensional mixer, and stir evenly. The mixing time is 0.5 to 4 hours, and the composite material transition layer is obtained. Layer mix;

[0050] b. First pour the friction material into the material cavity of the steel mould, then pour the mixed material of the transition layer of the composite material into the upper layer of the friction material in the material cavity of the steel mold, and mix the mixture of the transition layer of the composite material with the friction material The materials are pressed at the same time to obtain compacts, and the pressing pressure of cold pressing is 100-1500MPa;

[0051] ...

Embodiment example 1

[0059] Use weighing equipment, weigh raw materials according to the weight and number ratio of each material raw material of composite material transition layer 2, take 68 parts of copper powder, 28 parts of iron powder, 4 parts of calcium sulfate, put the above-mentioned raw materials in the three-dimensional mixer, Stir evenly, and the mixing time is 0.5h to obtain the mixture of the transition layer of the composite material;

[0060] Pour the friction material raw material into the material cavity of the steel mold, then pour the mixture of the transition layer of the composite material into the upper layer of the friction material in the material cavity of the steel mold, and mix the mixture of the transition layer of the composite material and the friction material at the same time Pressing to obtain a compact, the cold forming pressing pressure is 750Mpa;

[0061] The steel back 1 was placed on the compact, and pressure-sintered in a hydrogen atmosphere sintering furnac...

Embodiment example 2

[0063] Using weighing equipment, weigh the raw materials according to the ratio of the weight and number of each material in the transition layer 2 of the composite material, take 68 parts of copper powder, 30 parts of iron powder, and 2 parts of potassium titanate, and put the above raw materials into the three-dimensional mixer , stir evenly, and the mixing time is 0.5h to obtain the mixture of the transition layer of the composite material;

[0064] Pour the friction material raw material into the material cavity of the steel mold, then pour the mixture of the transition layer of the composite material into the upper layer of the friction material in the material cavity of the steel mold, and mix the mixture of the transition layer of the composite material and the friction material at the same time Pressing to obtain a compact, the cold forming pressing pressure is 300Mpa;

[0065] Place the steel back 1 on the green compact, pressurize and sinter in a hydrogen atmosphere ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com