A square core optical fiber

A core fiber, core layer technology, applied in the direction of multi-layer core/cladding fiber, cladding fiber, optical waveguide light guide, etc., can solve the problems of poor feasibility, difficult to improve coupling efficiency, difficult to control rectangular quartz tube, etc. Achieve the effect of easy control of core aspect ratio and core-skin ratio, improved mode field matching and coupling efficiency, and improved mode division multiplexing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

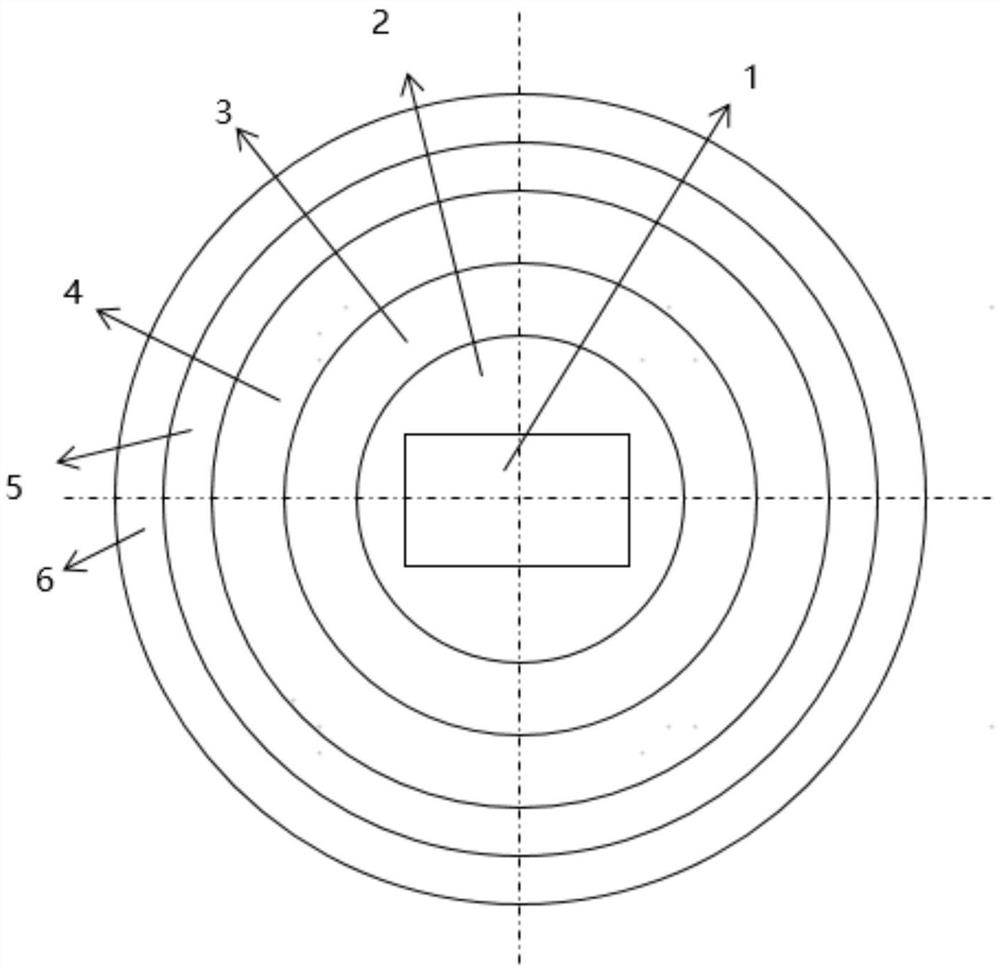

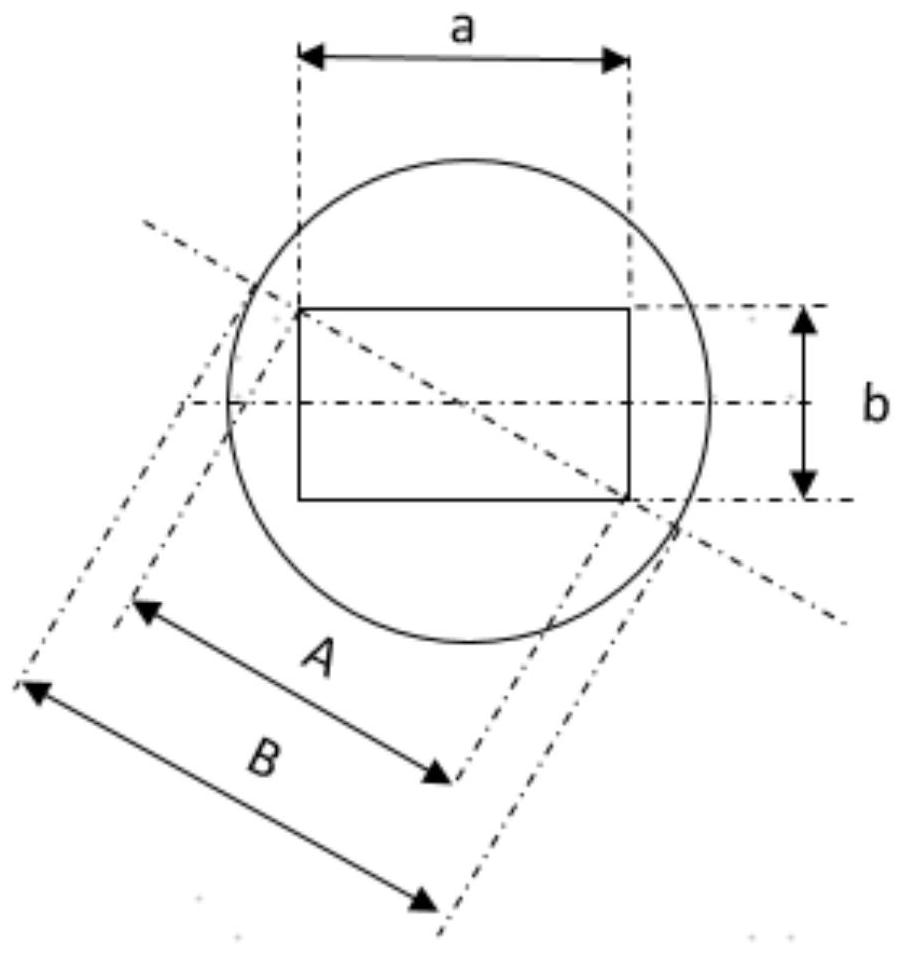

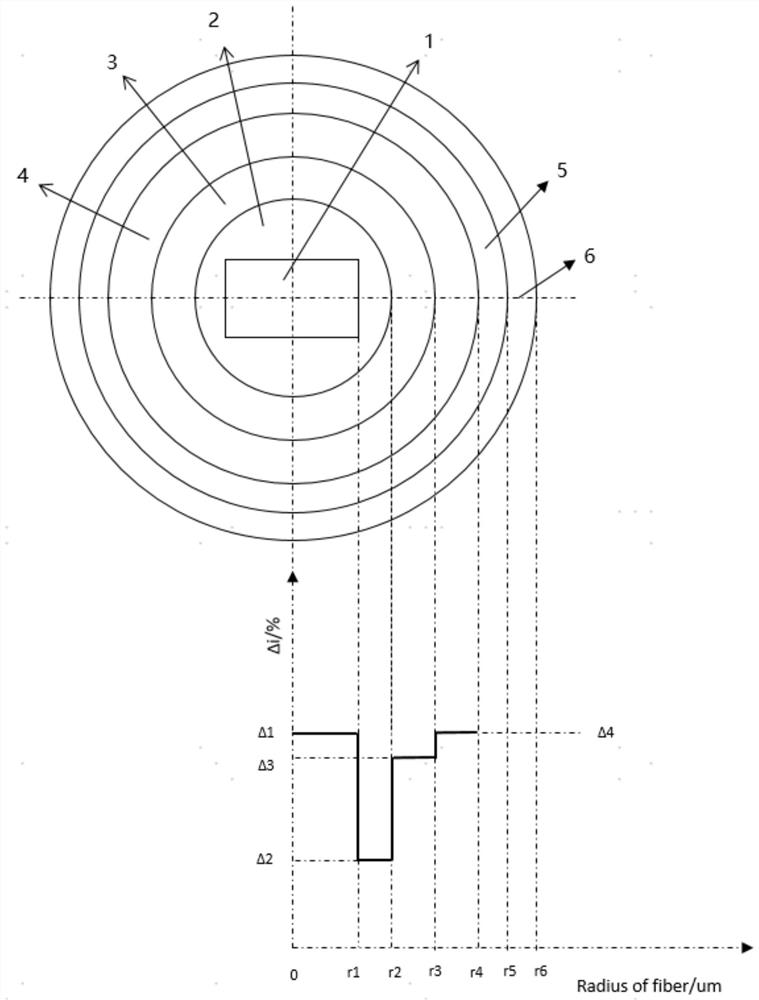

[0026] The first example is Figure 4 As shown, the square core optical fiber comprises a core layer 1, an inner cladding layer 2, an intermediate cladding layer 3, an outer cladding layer 4 and an inner coating layer 5 and an outer coating layer 6 of a resin coating layer; the shape of the core layer is a rectangle (rectangular or square), the relative refractive index difference Δ1 of the core layer is 0% to 0.3%, the aspect ratio a / b of the core layer is 2.0 to 3.0, the core layer length a is 16 to 30 μm, and the core layer width b is 5 ~15μm, the core layer is composed of silicon dioxide prepared by PCVD, the silicon dioxide can be pure silicon dioxide, or doped with germanium or fluorine, or both doped with germanium and fluorine, or doped with germanium and fluorine One or two kinds of alkali metals are added; the inner cladding layer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com