Preparation method of diamine ternary eutectic solvent and application of diamine ternary eutectic solvent to efficient capture of SO2

A low eutectic solvent, SO2 technology, applied in separation methods, chemical instruments and methods, dispersed particle separation and other directions, can solve the problems of complicated synthesis steps, expensive raw materials, weak physical effects, etc., and achieves simple and efficient operation and simple synthesis method. , the effect of efficient capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

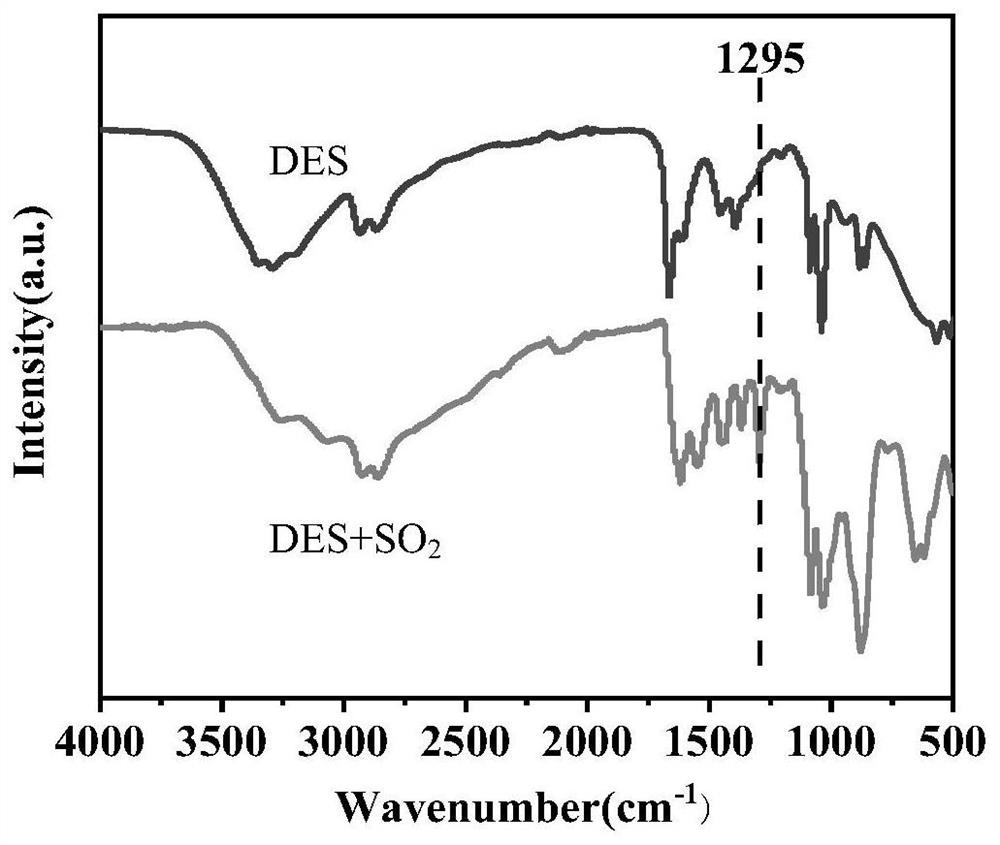

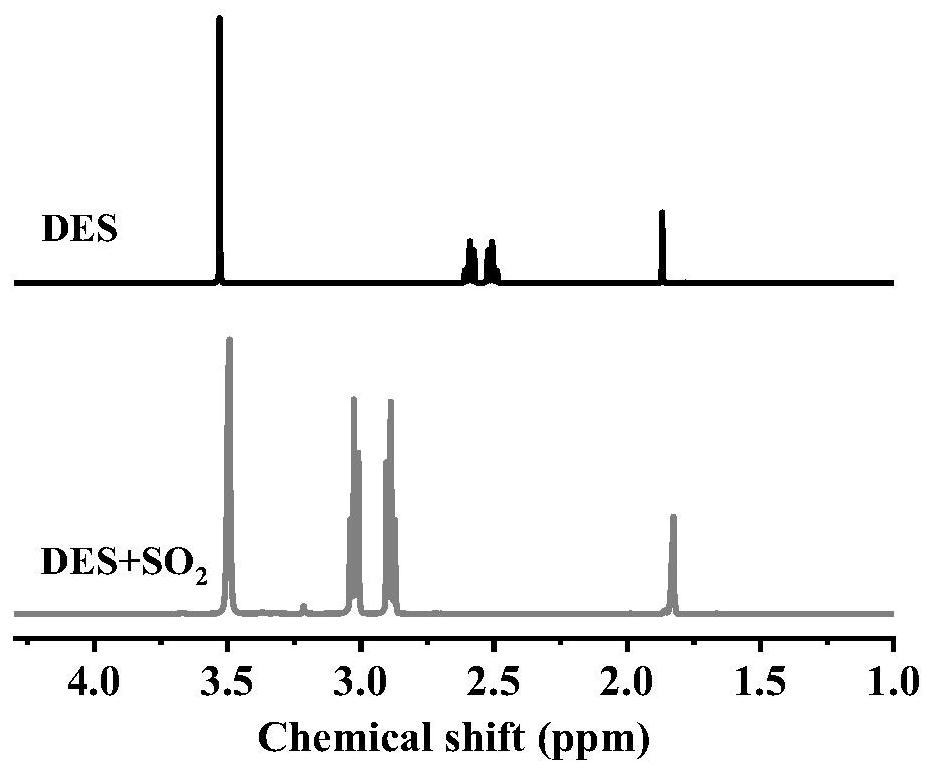

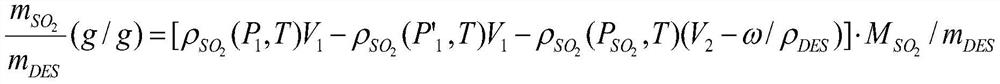

[0026] Weigh 0.1000g of pre-prepared diamine tertiary DES (the ratio of diethylenetriamine, acetamide and ethylene glycol is 1:1:2, and stir for 2 hours under the condition of 80°C oil bath to synthesize ) placed in the absorption tank and stirred with a magnetic stirrer, the absorption tank and the gas storage tank were sealed and then placed in a constant temperature water bath with precise temperature control at 25°C, filled with SO 2 , the absorption reaches equilibrium and remains unchanged for 2 hours, and the maximum absorption capacity is 0.82g / g.

Embodiment 2

[0028] Weigh 0.1000g of pre-prepared diamine tertiary DES (the ratio of diethylenetriamine, acetamide and ethylene glycol is 1:1:2, and stir for 2 hours in an oil bath at 70°C to synthesize ) placed in the absorption tank and stirred with a magnetic stirrer, the absorption tank and the gas storage tank were sealed and then placed in a constant temperature water bath with precise temperature control at 25°C, filled with SO 2 , the absorption reached equilibrium and remained unchanged for 2 hours, and the maximum absorption capacity was 0.74g / g.

Embodiment 3

[0030] Weigh 0.1000g of pre-prepared diamine tertiary DES (the ratio of diethylenetriamine, acetamide and ethylene glycol is 1:1:2, and stir for 2 hours in an oil bath at 90°C to synthesize ) placed in the absorption tank and stirred with a magnetic stirrer, the absorption tank and the gas storage tank were sealed and then placed in a constant temperature water bath with precise temperature control at 25°C, filled with SO 2 , the absorption reaches equilibrium and remains unchanged for 2 hours, and the maximum absorption capacity is 0.71g / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com