Quick-setting modified unsaturated resin for steel bridge deck maintenance, preparation method and mixture preparation method

An unsaturated, steel bridge deck technology, applied in the field of resin materials for road and bridge pavement, can solve the problems of high construction environment requirements, prone to rutting and secondary cracking at the repair site, so as to improve the overall mechanical properties, shorten the curing time, The effect of alleviating traffic pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

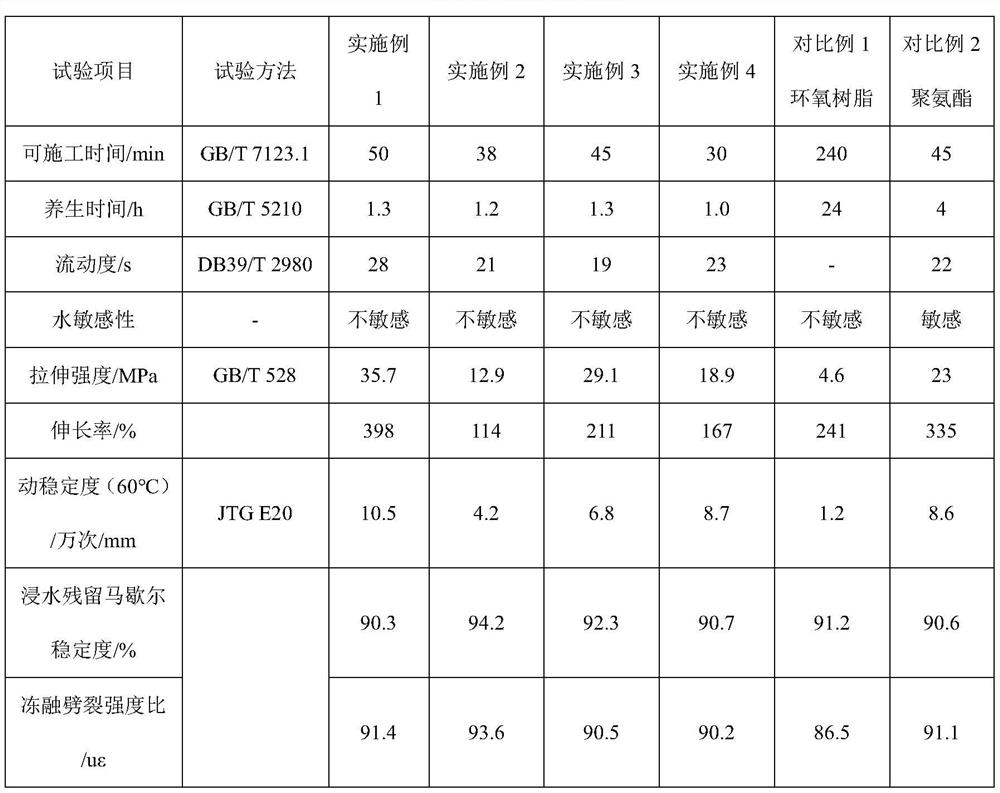

Embodiment 1

[0045] The preparation process of modified unsaturated resin is as follows:

[0046] A1. Add 160 parts of unsaturated resin monomer 1,2-propylene glycol, 150 parts of phthalic anhydride, and 100 parts of maleic anhydride into the reaction kettle, and react at 200-230°C under the protection of inert gas to obtain polyester ;

[0047] A2. Add 20 parts of modified material PA6 to the polyester, and continue to react for 0.5~1h;

[0048] A3. Add the material prepared in A2 into a reaction kettle containing 170 parts of styrene polymerization inhibitor, and mix at 60-80° C. to obtain a modified unsaturated resin.

[0049] The preparation method of the fast-curing modified unsaturated resin mixture for steel bridge deck maintenance is as follows:

[0050] S1. 40 parts of unsaturated resin (191), 60 parts of modified unsaturated resin, 10 parts of graphene powder, 10 parts of silsesquioxane, 10 parts of dopa (DOPA) and 1 part of accelerator (cycloalkane Cobalt acid) was added into...

Embodiment 2

[0054] The preparation process of modified unsaturated resin is as follows:

[0055] A1. Add 160 parts of unsaturated resin monomer 1,2-propylene glycol, 150 parts of phthalic anhydride, and 100 parts of maleic anhydride into the reaction kettle, and react at 200-230°C under the protection of inert gas to obtain polyester ;

[0056] A2. Add 20 parts of modified material PA6 to the polyester, and continue to react for 0.5~1h;

[0057] A3. Add the material prepared in A2 into a reaction kettle containing 170 parts of styrene polymerization inhibitor, and mix at 60-80° C. to obtain a modified unsaturated resin.

[0058] The preparation method of the fast-curing modified unsaturated resin mixture for steel bridge deck maintenance is as follows:

[0059] S1. 80 parts of unsaturated resin (196), 20 parts of modified unsaturated resin, 2 parts of graphene powder, 5 parts of silsesquioxane, dopa (3PEG-DOPA) 3 ) and 2 parts of accelerator (DMA) were sequentially added into 10 parts ...

Embodiment 3

[0063] The preparation process of modified unsaturated resin is as follows:

[0064] A1. Add 160 parts of unsaturated resin monomer 1,2-propylene glycol, 150 parts of phthalic anhydride, and 100 parts of maleic anhydride into the reaction kettle, and react at 200-230°C under the protection of inert gas to obtain polyester ;

[0065] A2. Add 20 parts of modified material PA6 to the polyester, and continue to react for 0.5~1h;

[0066] A3. Add the material prepared in A2 into a reaction kettle containing 170 parts of styrene polymerization inhibitor, and mix at 60-80° C. to obtain a modified unsaturated resin.

[0067] The preparation method of the fast-curing modified unsaturated resin mixture for steel bridge deck maintenance is as follows:

[0068] S1. 50 parts of unsaturated resin (323), 50 parts of modified unsaturated resin, 8 parts of graphene powder, 7 parts of silsesquioxane, dopa (5PEG-DOPA) 3 ) and 1.5 parts of accelerator (DMT) were sequentially added to 18 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com