Single-component thermocuring organic silicon adhesive for bonding electric kettle and preparation method of single-component thermocuring organic silicon adhesive

An electric kettle, one-component technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of poor storage performance, poor adhesion of substrates, and inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

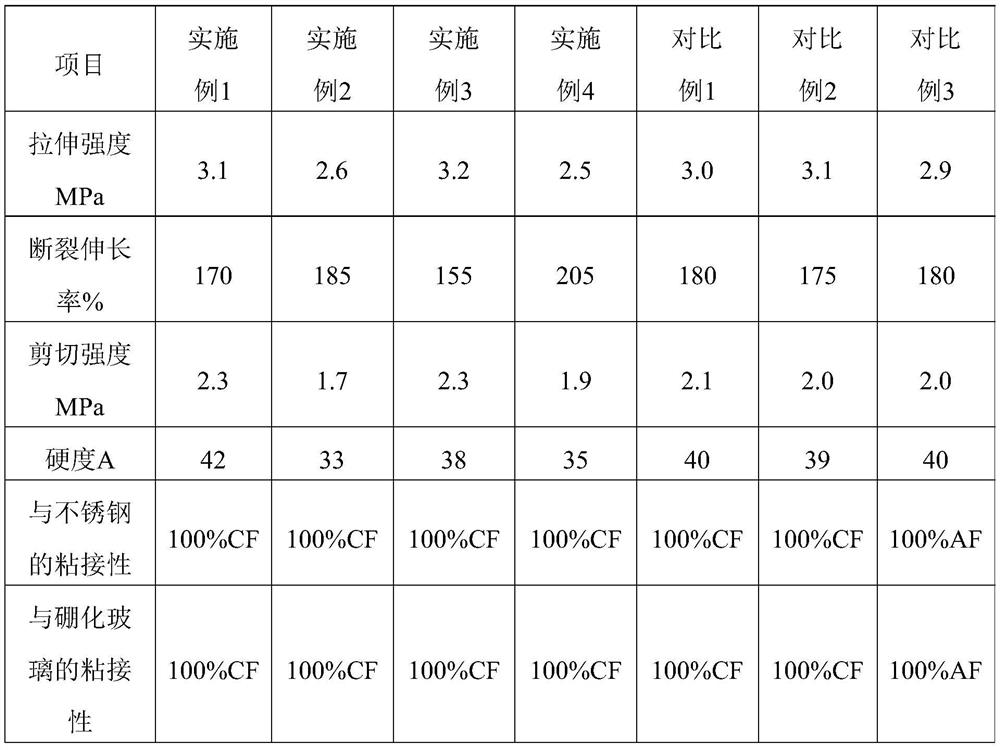

Examples

Embodiment 1

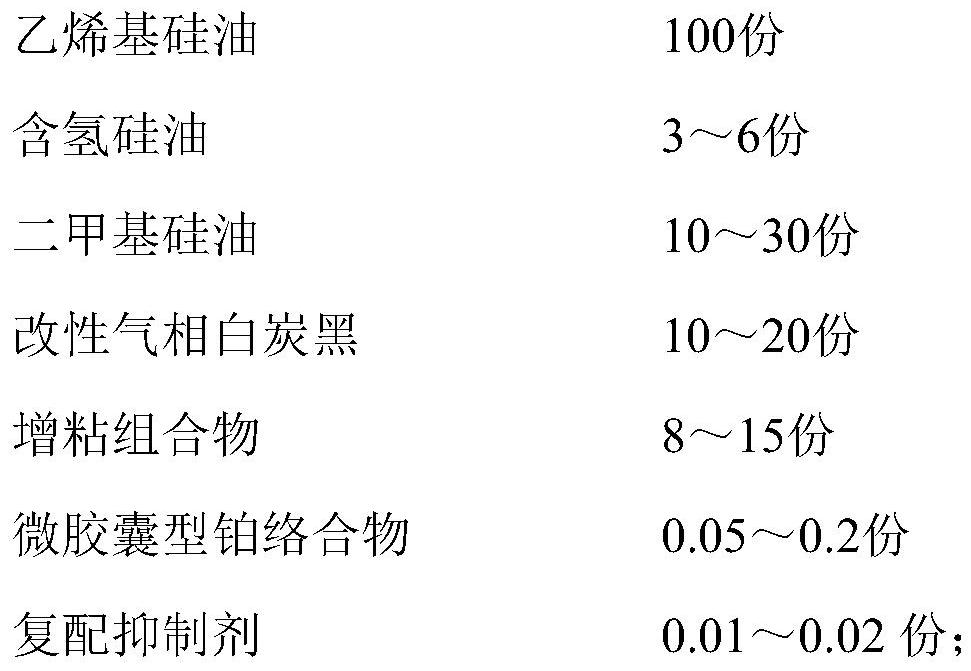

[0033] A kind of one-component heat-curable silicone adhesive adhesive for electric kettle bonding of this embodiment, the parts by weight of each component in its formula are:

[0034] Vinyl silicone oil 100 parts

[0035] 4 parts hydrogen silicone oil

[0036] 12 parts of simethicone

[0037] Modified fumed silica 11 parts

[0038] 8 parts viscosifying composition

[0039] Microencapsulated platinum complex 0.2 parts

[0040] Compound inhibitor 0.01 part.

[0041] Among them, the viscosity of vinyl silicone oil is 10000mpa.s, and its vinyl content is 0.15%.

[0042] Among them, hydrogen-containing silicone oil is a compound of low-hydrogen-containing silicone oil and high-hydrogen-containing silicone oil. The hydrogen content of low-hydrogen-containing silicone oil is 0.36%, and the hydrogen content of high-hydrogen-containing silicone oil is 1.58%. The compounding ratio of silicone oil is 1:0.9.

[0043] Wherein, the viscosity of simethicone is 350mpa.s.

[0044]Whe...

Embodiment 2

[0058] A kind of one-component heat-curable silicone adhesive adhesive for electric kettle bonding of this embodiment, the parts by weight of each component in its formula are:

[0059] Vinyl silicone oil 100 parts

[0060] 5 parts of hydrogen silicone oil

[0061] 20 parts of simethicone

[0062] Modified fumed silica 15 parts

[0063] 10 parts of viscosifying composition

[0064] Microencapsulated platinum complex 0.15 parts

[0065] Compound inhibitor 0.01 part.

[0066] Among them, the viscosity of vinyl silicone oil is 5000mpa.s, and its vinyl content is 0.3%.

[0067] Among them, the hydrogen-containing silicone oil is a compound of low-hydrogen-containing silicone oil and high-hydrogen-containing silicone oil. The hydrogen content of low-hydrogen-containing silicone oil is 0.45%, and the hydrogen content of high-hydrogen-containing silicone oil is 1.55%. The compounding ratio of silicone oil is 1:0.9.

[0068] Wherein, the viscosity of simethicone is 100mpa.s.

...

Embodiment 3

[0078] A kind of one-component heat-curable silicone adhesive adhesive for electric kettle bonding of this embodiment, the parts by weight of each component in its formula are:

[0079] 100 parts of vinyl silicone oil,

[0080] 5 parts of hydrogen silicone oil

[0081] 25 parts of simethicone

[0082] Modified fumed silica 15 parts

[0083] 12 parts of tackifying composition

[0084] Microencapsulated platinum complex 0.15 parts

[0085] Compound inhibitor 0.02 part.

[0086] Among them, the viscosity of vinyl silicone oil is 20000mpa.s, and its vinyl content is 0.15%.

[0087] Among them, the hydrogen-containing silicone oil is a compound of low-hydrogen-containing silicone oil and high-hydrogen-containing silicone oil. The hydrogen content of low-hydrogen-containing silicone oil is 0.5%, and the hydrogen content of high-hydrogen-containing silicone oil is 1.6%. The compounding ratio of silicone oil is 1:1.2.

[0088] Wherein, the viscosity of simethicone is 500mpa.s. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com