Device and method for recovering low-calorific-value converter gas

A technology of converter gas and low calorific value, which is applied in waste gas treatment, manufacturing converters, climate sustainability, etc., and can solve problems such as waste of energy, air pollution, and low CO content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] The average flow rate of converter gas recovery during converter blowing in a certain iron and steel enterprise is 30000m3 / h, and the converter gas pressure during recovery is 2-3Kpa.

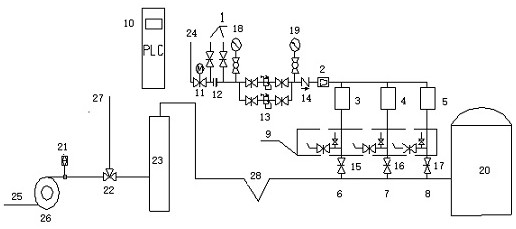

[0036] 1. From the upper guide pipe of the refined coke oven gas pipeline with a pressure of 0.3MPa to the vicinity of the converter gas pipeline in front of the converter gas cabinet, it is connected to the nozzle, and the electric butterfly valve, nitrogen purge head 1, and eyes are installed on the refined coke oven gas pipeline in sequence according to the flow direction of the medium Valve, nitrogen purge head 2, pressure gauge 1, pressure reducing valve group, pressure gauge 2, check valve and flowmeter, the main pipe behind the flowmeter is connected to four branch pipes. The four branch pipes are connected in parallel, and each branch pipe is equipped with a nozzle control box, a nozzle control gate valve and a nozzle according to the flow direction of the medium. Reduce the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com