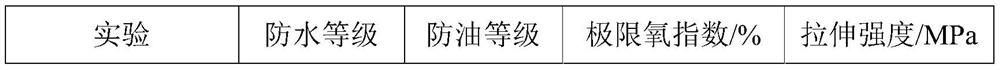

Flame-retardant, waterproof and oil-proof finishing agent and preparation method thereof

A waterproof and oil-proof finishing agent technology, which is applied in the direction of flame-retardant fibers, fiber treatment, textiles and papermaking, etc., can solve problems such as lack, and achieve the effects of improving fabric strength, high flame-retardant performance, and good waterproof and oil-proof effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The second aspect of the present invention provides a method for preparing a flame-retardant waterproof and oil-repellent finishing agent, comprising the following steps:

[0050] S1: Add the dried and dehydrated acrylate into the reactor, then add the solvent, and stir until dissolved at 60-70 degrees Celsius;

[0051] S2: Add fluoroester and compound A containing ring structure to step S1, cool down to 20-35 degrees Celsius, add initiator, polyoxyethylene lauryl ether, stir for 10-30 minutes, then stop stirring, and react 1- 2 hours;

[0052] S3: washing and purifying the reactant obtained in step S2 with methanol to obtain a flame-retardant, waterproof and oil-repellent finishing agent.

[0053] The method of using the flame-retardant, waterproof and oil-repellent finishing agent in the present invention is not particularly limited, and the fabric can be finished and used according to methods well known to those skilled in the art. For example, after diluting the f...

Embodiment 1

[0058] A flame-retardant waterproof and oil-repellent finishing agent, the preparation raw materials include 60 parts of stearyl acrylate, 24 parts of hexafluoro-2-methylisopropyl acrylate, 15 parts of compound A, azobisisobutyronitrile 0.03 parts, 5 parts of polyoxyethylene lauryl ether, and 100 parts of methyl ethyl ketone.

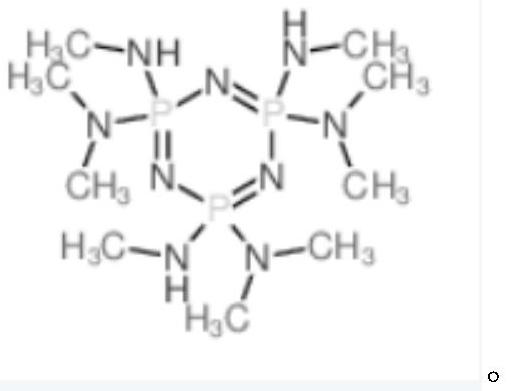

[0059] The structural formula of the described compound A part is: CAS number 6633-79-0.

[0060] The weight ratio of the stearyl acrylate to hexafluoro-2-methylisopropyl acrylate is 2.5:1.

[0061] The weight ratio of the hexafluoro-2-methylisopropyl acrylate to the compound A is 1.6:1.

[0062] Octadecyl acrylate, CAS No.: 4813-57-4, purchased from Zhejiang Kangde New Material Co., Ltd.; Hexafluoro-2-methylisopropyl acrylate, CAS No.: 53038-41-8, purchased from Xiamen Hui Jia Biotechnology Co., Ltd.

[0063] A preparation method of a flame-retardant waterproof and oil-repellent finishing agent, comprising the following steps:

[0064] S1: Add th...

Embodiment 2

[0068] A flame-retardant waterproof and oil-repellent finishing agent, the specific implementation method of which is the same as that of Example 1, except that octadecyl acrylate is replaced by dodecyl acrylate, CAS number: 2156-97-0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com