Preparation method of composite substrate, composite substrate and composite film

A composite substrate and composite film technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as increasing the risk of debonding of radio frequency filters, reducing the service life of radio frequency filters, and falling off functional films. , to reduce the risk of debonding, prolong the service life, and avoid falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

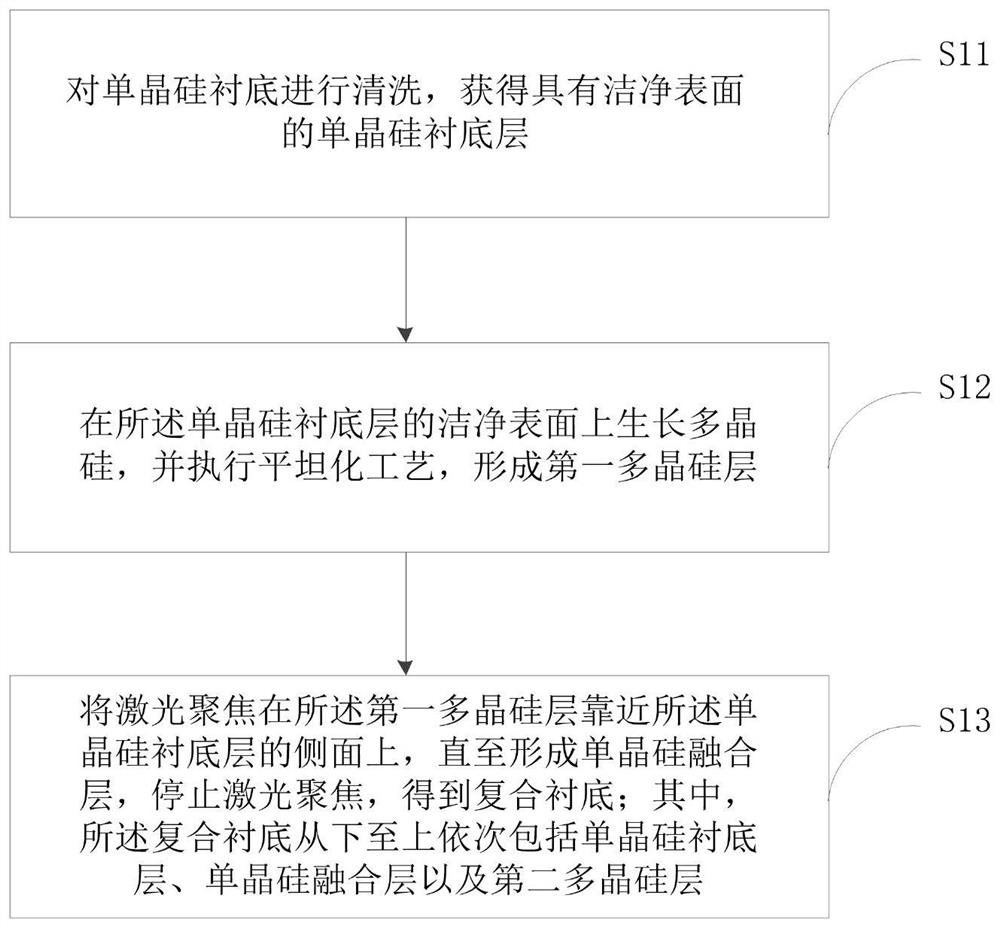

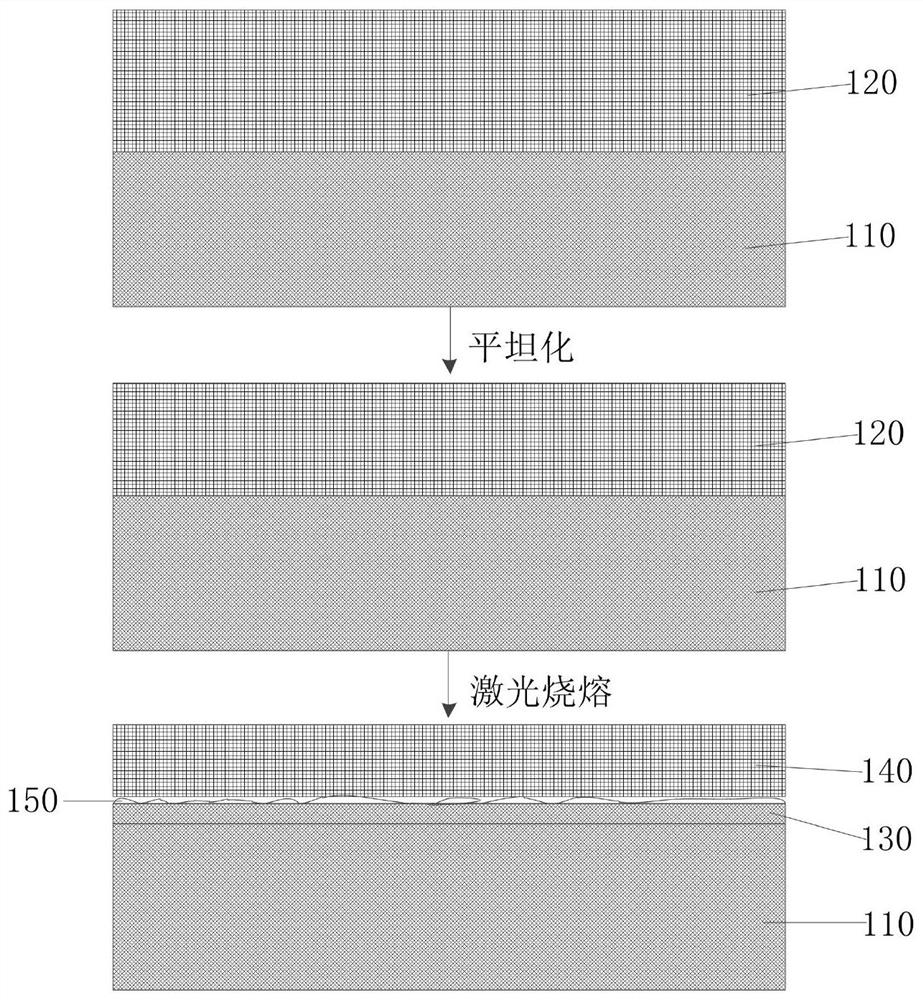

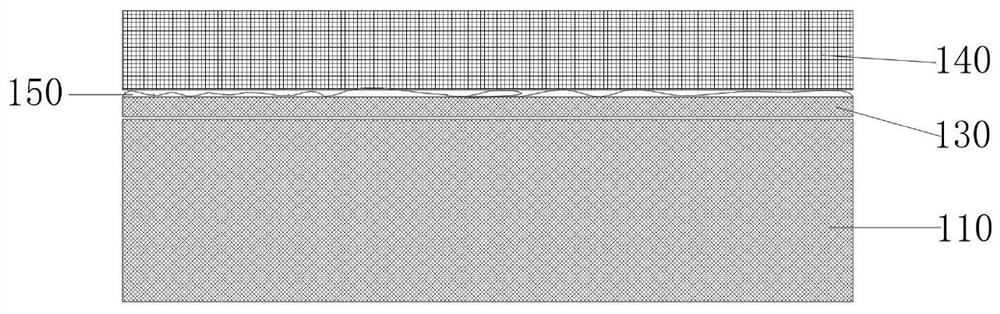

[0026] The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present application. Obviously, the described embodiments are only some of the embodiments of the present application, not all of them. Based on the embodiments in this application, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of this application.

[0027] As mentioned in the background technology of this application, in the prior art, the volume of the radio frequency filter is relatively small, and the cutting size of the lithium tantalate thin film wafer needs to be smaller. Therefore, the bonding force between the layers of the lithium tantalate thin film wafer is It becomes a key factor in the utilization rate of lithium tantalate film and the yield of devices. If the adhesion of polysilicon depos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com