Amino polyether polyol for low-boiling-point low-density quick-release system, preparation method, rigid polyurethane foam prepared from amino polyether polyol and preparation method of rigid polyurethane foam

A polyether polyol, amino polyether technology, applied in the field of polyols, can solve the problems of bulging and debonding, poor foam curing, short foam curing time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

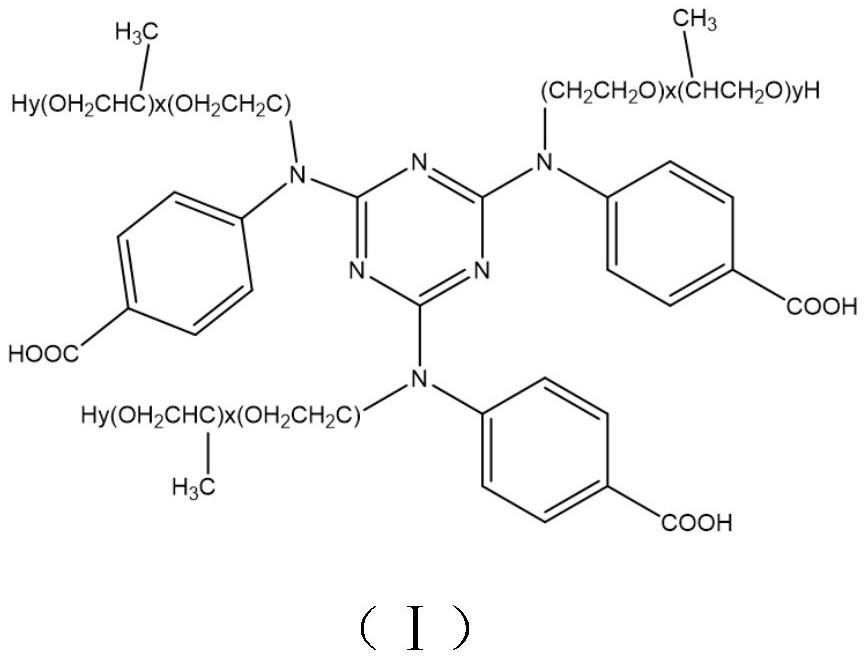

[0064] 1) Add water (17775g, 987.5mol) and 2,4,6-tris[(p-carboxyphenyl)amino]-1,3,5-triazine (1222g, 2.51mol) into the reactor, nitrogen replacement Pressure test, start stirring and heat to 100°C. Add 340 g of propylene oxide into the reactor by metering a flow rate of 650 g / h. Then the reaction was continued for 1 hour, and then the temperature was raised to 125° C. for another 1 hour.

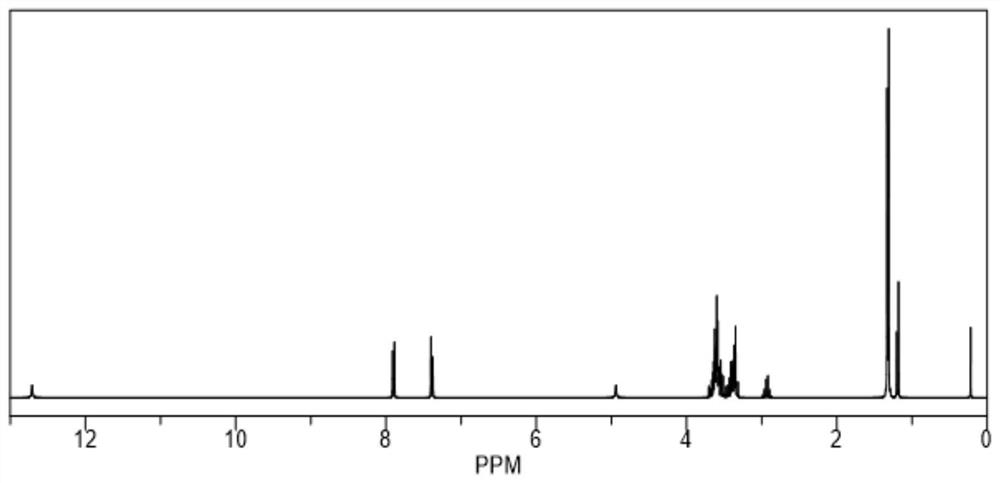

[0065] 2) Vacuum and remove water at 115°C for 2 hours. Add remaining propylene oxide 410g by metering flow rate 750g / h. After continuing the reaction for 2 hours, the temperature was raised to 145° C. for another 3 hours to obtain the final product amino polyether polyol. In the obtained polyol, x and y are 0 and 6 respectively, and the hydroxyl value is 450 mgKOH / g in the titration test using the method of phthalic anhydride esterification, and the functionality is 6 by calculation. The NMR data are as follows: 1H NMR (300MHz, DMSO) δ=12.74(s, 3H), 7.90(d, J=4.8Hz, 6H), 7.39(d, J=4.8Hz...

Embodiment 2

[0068] 1) Add water (14150g, 786.1mol) and 2,4,6-tris[(p-carboxyphenyl)amino]-1,3,5-triazine (1205g, 2.48mol) into the reactor, nitrogen replacement Pressure test, start stirring and heat to 90°C. Measured at a flow rate of 600g / h, add 300g of ethylene oxide and propylene oxide into the reactor at a mass ratio of 3:7. Then continue to react for 2.5h, then raise the temperature to 120°C and react for another 2.5h.

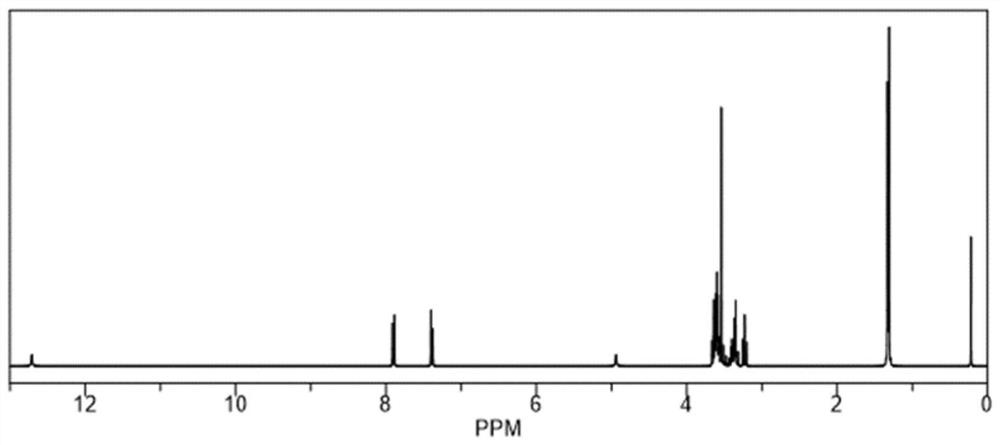

[0069] 2) Vacuum and remove water at 100°C for 1 hour. According to flow rate 400g / h metering add remaining epoxide 360g, the mass ratio of ethylene oxide and propylene oxide is 3:7. After continuing the reaction for 2.5 hours, the temperature was raised to 140° C. for another 3 hours to obtain the final product amino polyether polyol. In the obtained polyol, x and y are 2 and 5 respectively, and the hydroxyl value is 500 mgKOH / g through titration test by the method of phthalic anhydride esterification, and the calculated functionality is 5.1. The NMR data are a...

Embodiment 3

[0073] A low-density quick-release 134a system polyurethane rigid foam, the raw material composition:

[0074] The mass ratio of combined polyether to foaming agent and polyisocyanate is 100:20:150, specifically:

[0075] The composition of the combined polyether is as follows: 91.6 parts of polyether composition, 3 parts of surfactant, 3.4 parts of composite catalyst, and 2.0 parts of distilled water;

[0076]Foaming agent (mass ratio): CP: 245fa: 134a = 11:7:2;

[0077] Polyisocyanate: Polymerized MDI, Wanhua PM-200 150 parts.

[0078] In combination polyether:

[0079] The polyether composition consists of 15 parts by weight of 2,4,6-tris[(p-carboxyphenyl)amino]-1,3,5-triazine polyether polyol (prepared in Example 2): sucrose polyether polyol Alcohol (hydroxyl value 410mgKOH / g, functionality 6.5) 51.6 parts, sorbitan polyether polyol (hydroxyl value 432mgKOH / g, functionality 5.8) 20 parts, glycerin polyether polyol (hydroxyl value 192mgKOH / g, functionality is 2.3) 5 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com