Patterned substrate, preparation method thereof, light emitting diode and preparation method of light emitting diode

A patterned substrate and substrate technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of decreased epitaxy surface ratio, epitaxy difficulties, unfavorable epitaxial epitaxial layers, etc., to improve quality and increase light output effect, the effect of reducing the dislocation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

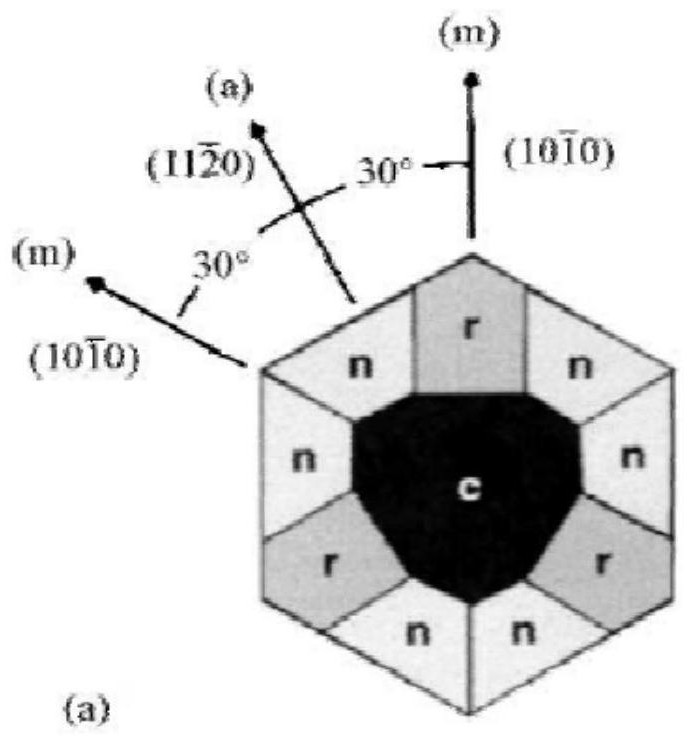

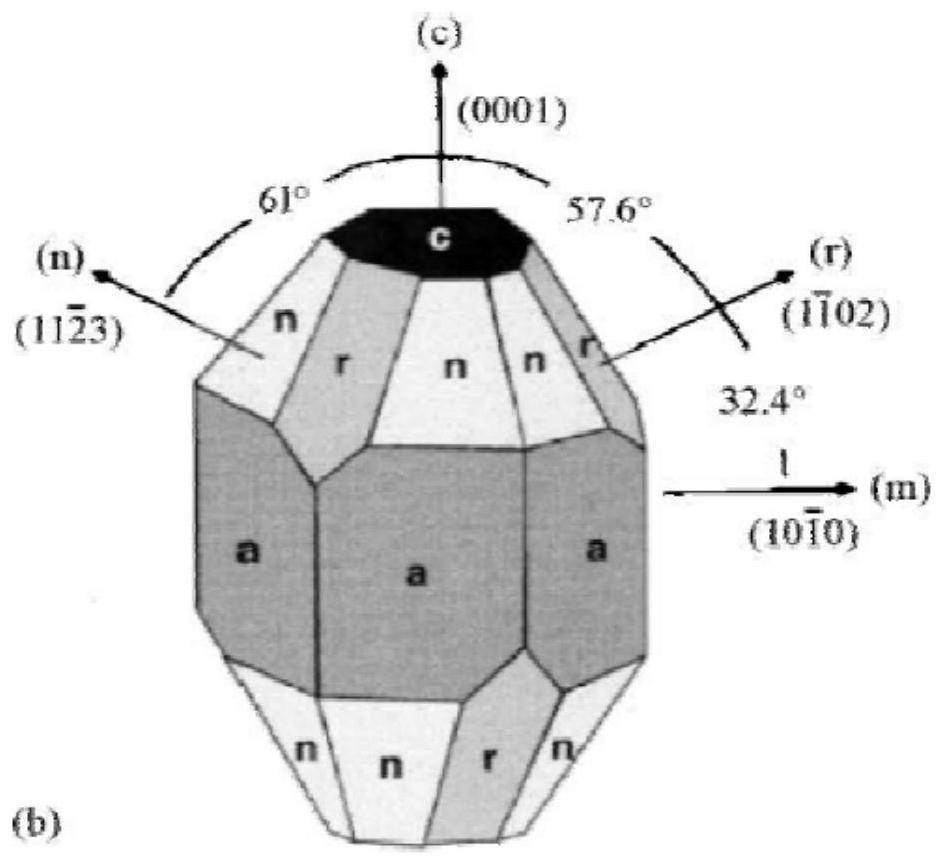

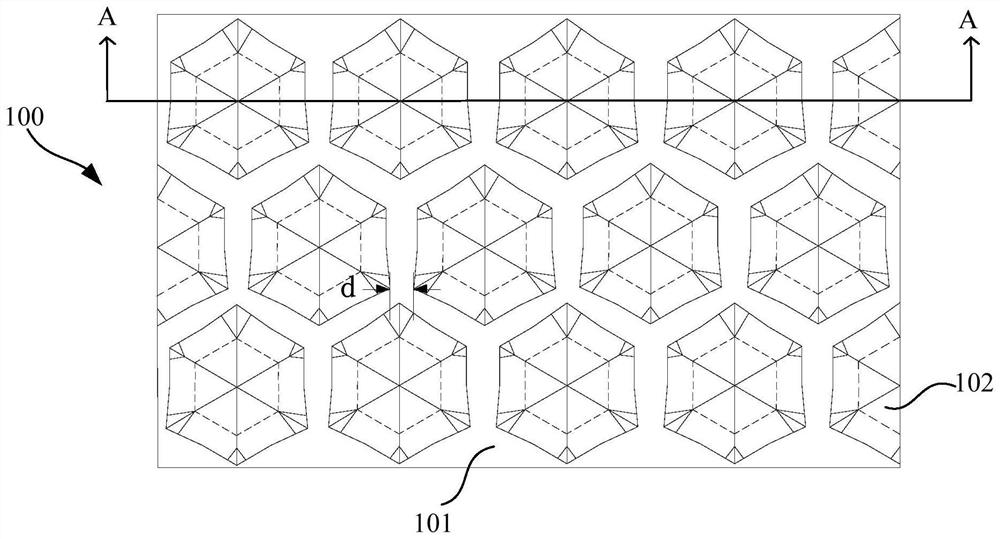

[0092] This embodiment provides a patterned substrate, which includes a substrate and a number of periodic and closely arranged pattern structures formed on the surface of the substrate, and the minimum distance d between adjacent pattern structures is less than or Equal to 0.1 μm. The graphic structure includes a first part formed on the surface of the substrate and a second part formed above the first part. The first part includes: a cylindrical part formed with an inscribed circle inscribed with the upper surface of the first part as a bottom surface. and a plurality of first protrusions and a plurality of second protrusions uniformly arranged around the cylindrical portion; the first protrusions and the second protrusions are spaced apart from each other, and the cross-sectional area of the first protrusions is greater than or equal to the second The cross-sectional area of the protrusion. Since the proportion of the epitaxial surface of the substrate exposed between ...

Embodiment 2

[0101] This embodiment discloses a method for preparing a patterned substrate, including: providing a substrate, forming several pattern structures on the surface of the substrate, and the pattern structures are periodically arranged closely on the surface of the substrate; adjacent patterns The minimum distance between structures is less than or equal to 0.1 μm. Wherein, the graphic structure includes a first part located on the surface of the substrate and a second part located above the first part, and the first part includes: a cylindrical part formed with an inscribed circle inscribed with the upper surface of the first part as a bottom surface; And the first protrusion and the second protrusion evenly arranged around the cylindrical part; area.

[0102] In one embodiment of the present invention, refer to Figures 5a-5f and 2a-2b, including:

[0103] S101: Provide a substrate, and form a nucleation inhibiting material layer on the surface of the substrate, where the m...

Embodiment 3

[0119] This embodiment discloses a light emitting diode, refer to Image 6 ; The light-emitting diode includes a substrate and an epitaxial layer formed on the surface of the substrate, wherein the substrate is a patterned substrate as in Embodiment 1 or 2, and the epitaxial layer is formed on the side of the patterned substrate with a pattern structure.

[0120] Specifically, refer to Image 6 , on the patterned side of the patterned substrate 100, the epitaxial layer composed of the first semiconductor layer 110, the active layer 120 and the second semiconductor layer 130 opposite to the type of the first semiconductor layer 110 is included in sequence; The first electrode 140 is formed on the second semiconductor layer 130 , and the second electrode 150 is formed on the first semiconductor layer 110 . Optionally, a transparent conductive layer, such as ITO, is further formed on the first semiconductor layer 130 and the second semiconductor layer 140; both the first electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com